System and method for bending strip material to create cutting dies

a technology of cutting dies and strips, applied in the direction of metal-working equipment, metal-working tools, metal-working tools, etc., can solve the problem that the method is often no longer economically viabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

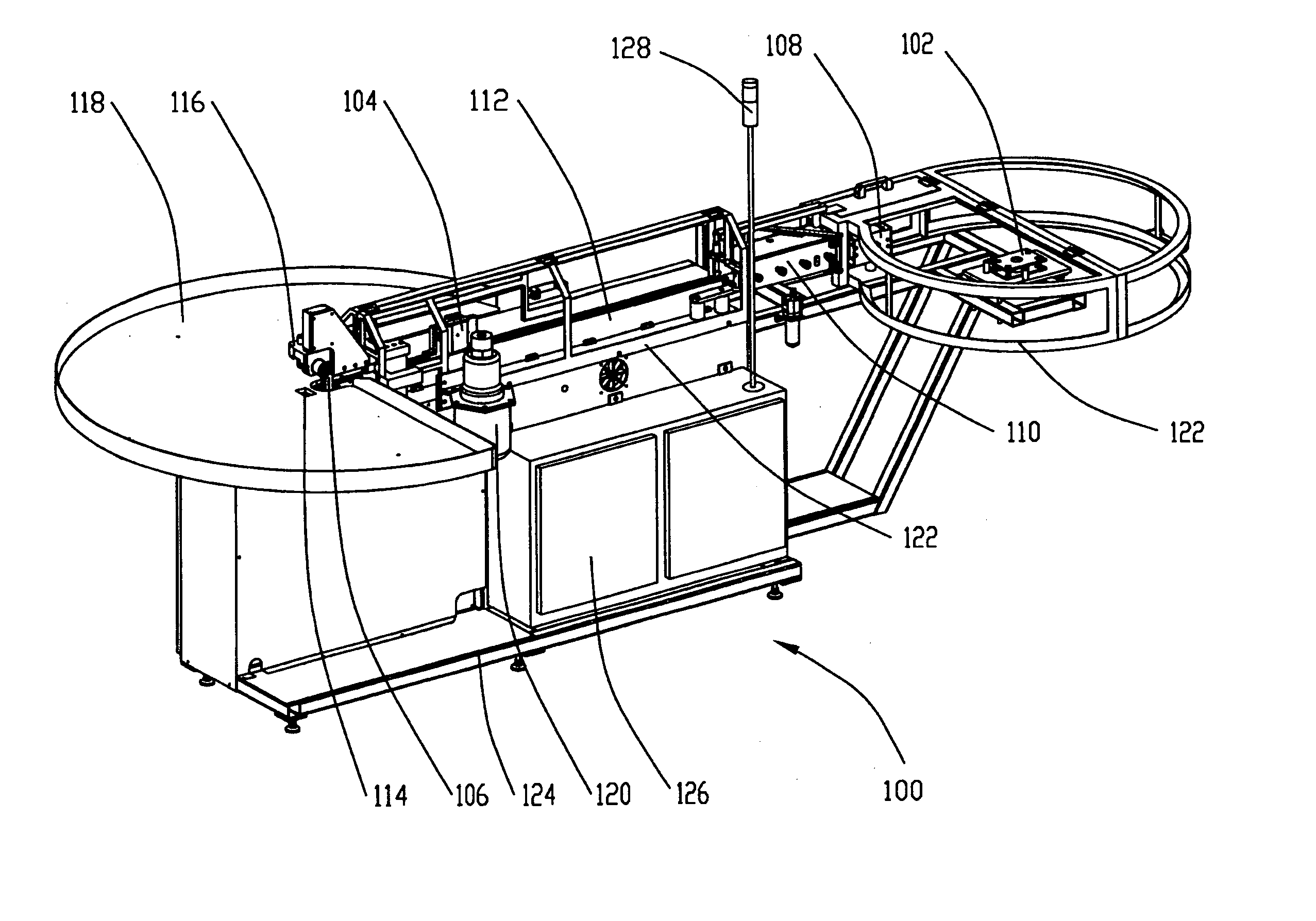

[0044] The production of an accurate cutting die is far from simple. To aid the reader in understanding the complexity of a cutting die, we refer now to FIG. 1a. FIG. 1a is an isometric view of cutting die shown generally as 10. Cutting die 10 is constructed from a piece for material 12 bent at various angles. Material 12 has a cutting edge 14. Cutting edge 14 may be one of many different shapes depending upon the product to be cut by the die 10. Material 12 may have many different characteristics, one having a cutting edge 14 that is heat treated, sharpened and serrated. Die 10 may be reinforced by braces 16 to ensure that die 10 does not deform during use. If used, braces 16 would typically be welded to material 12. Braces 16 may also optionally include one or more mounting holes 18 to allow die 10 to be attached to a cutting board or press (not shown).

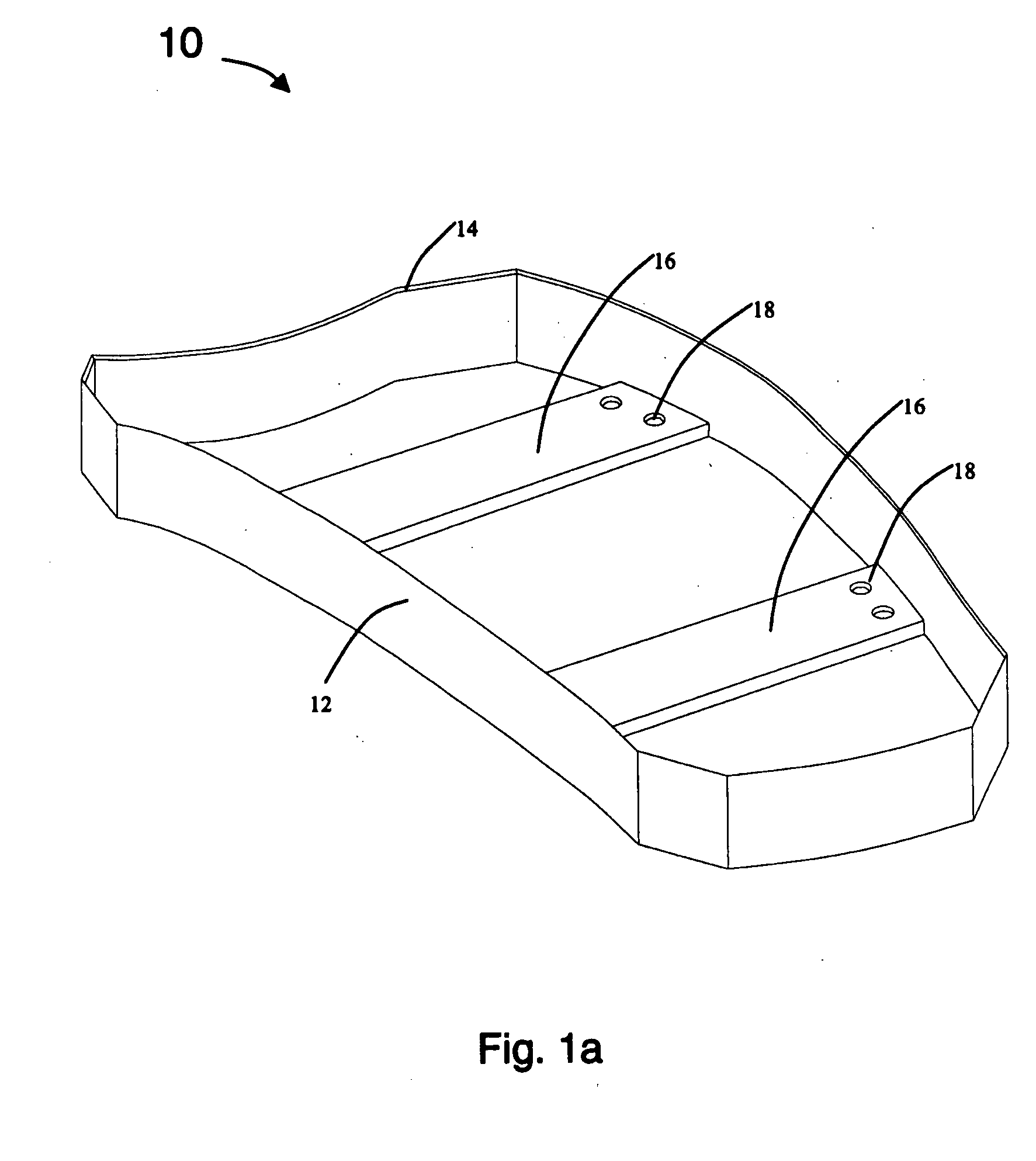

[0045] Referring now to FIG. 1b an isometric view of a cutting die with nicks is shown generally as 20. Cutting die 20 is of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com