Bender for bending material, such as tube, rod section and/or metal wire rod

A metal wire, bending tube technology, applied in the field of bending machines, can solve the problems of precise dismantling and accurate positioning of difficult-to-bend parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

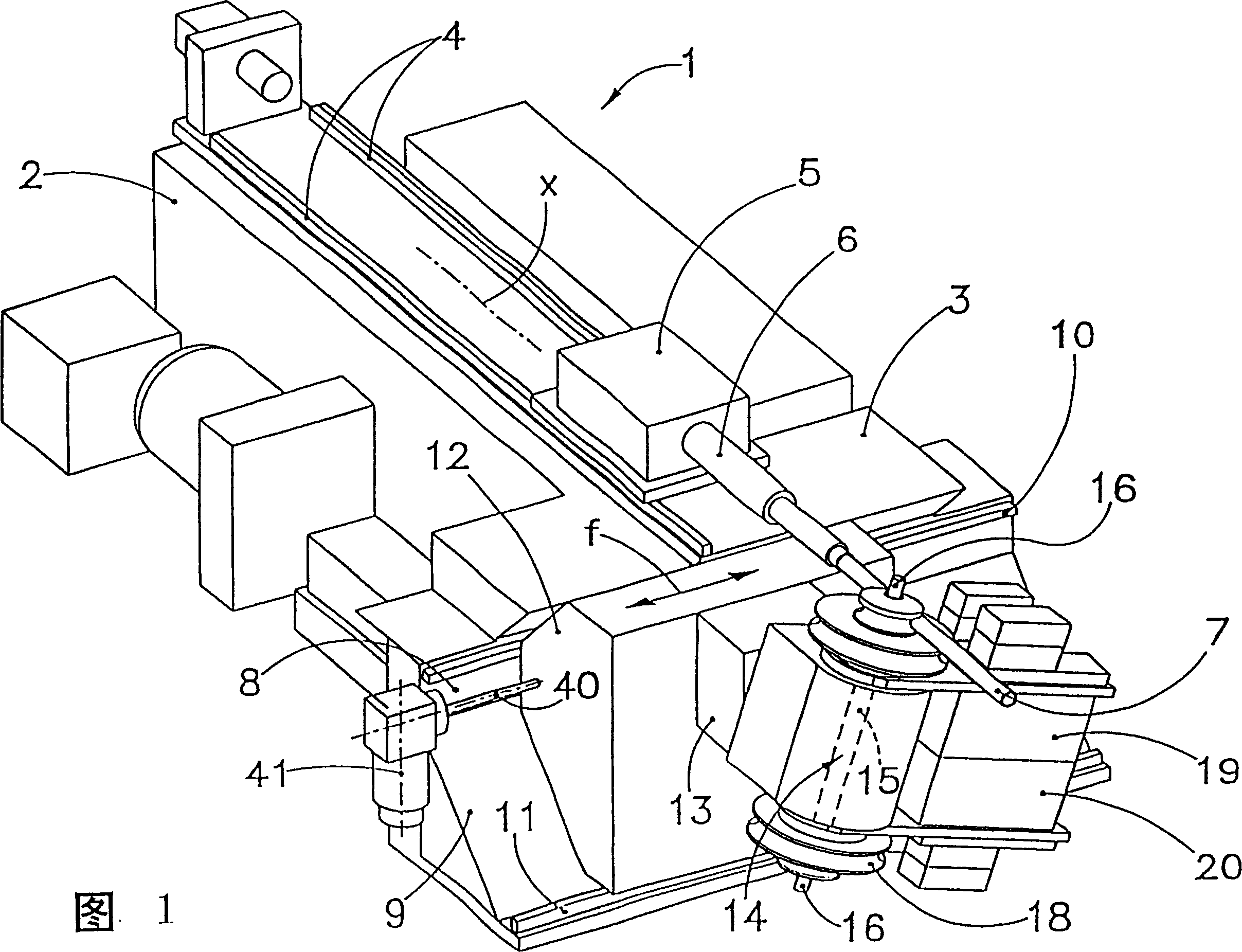

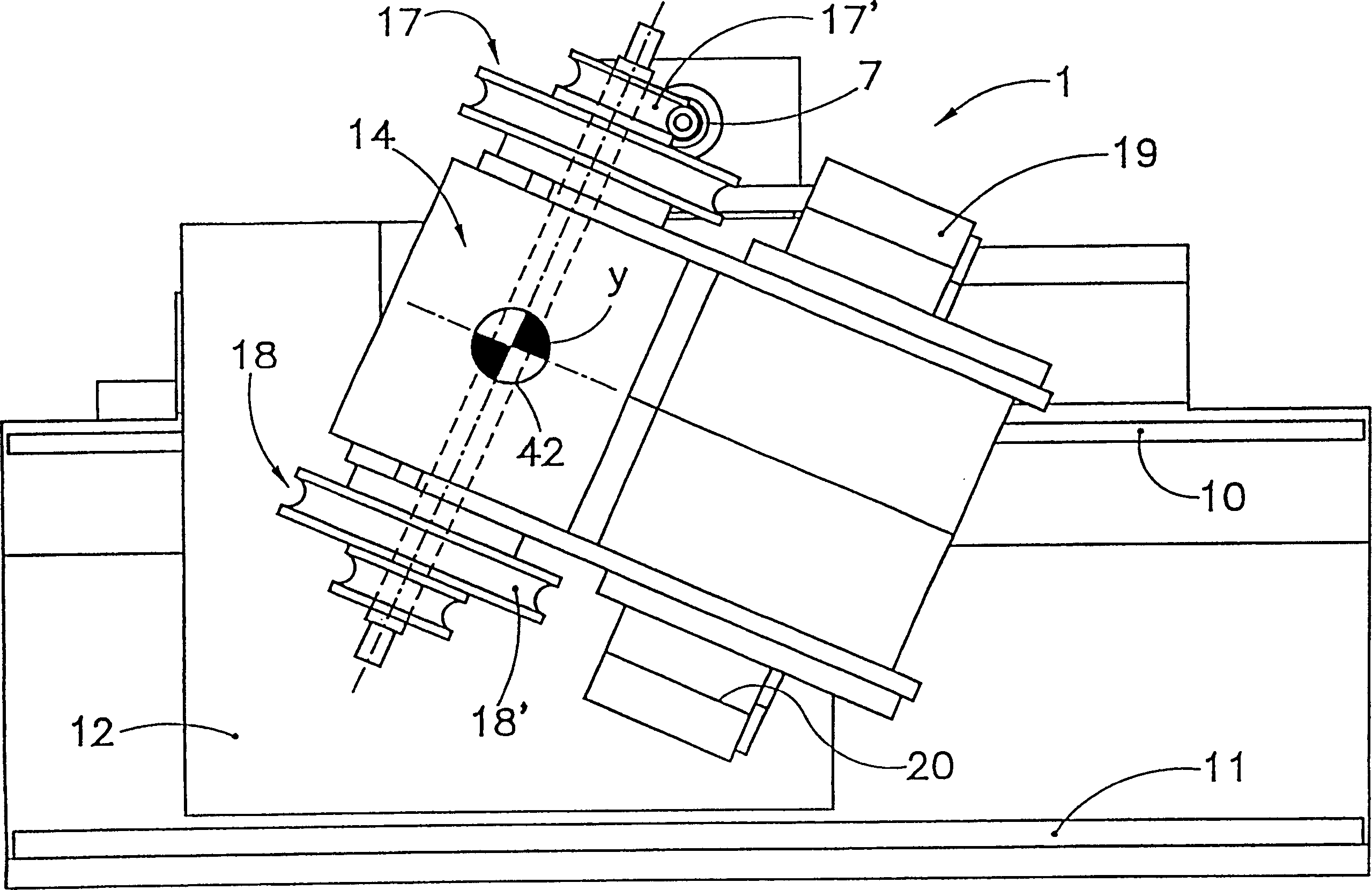

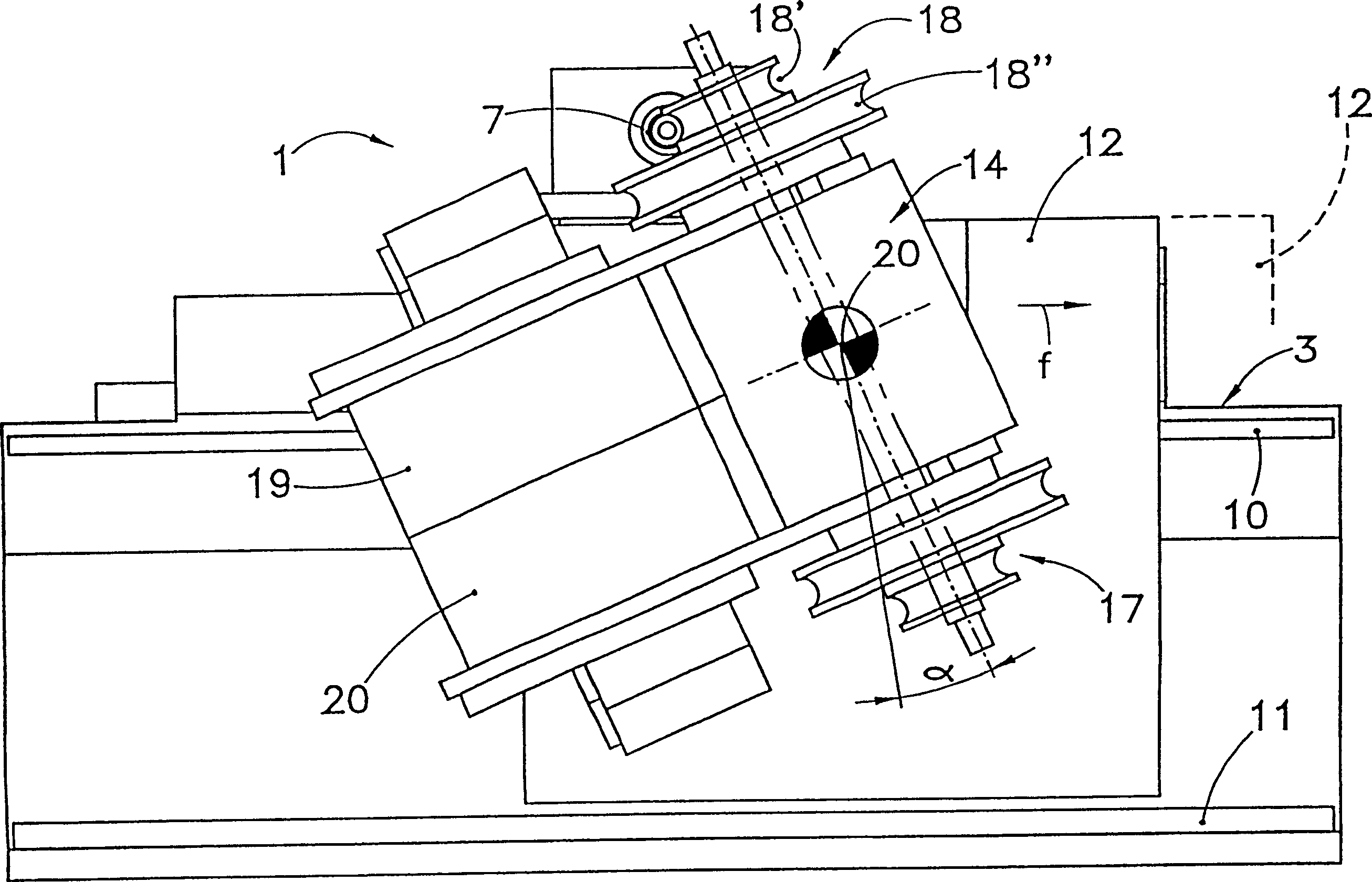

[0021] As shown in FIG. 1 , the bending machine, generally designated 1 , is equipped with a T-shaped machine comprising a longitudinal section 2 and a cross piece 3 forming the front end of the bending machine 1 .

[0022] On its top face, the machine tool is equipped with precisely parallel rail mechanisms 4, on which a known bracket 5 is movably supported, which includes a Indicates) pipe clamp 6 that rotates.

[0023] On its front side, the cross piece 3 is equipped with a vertical wall 8 which intersects an oblique forward wall 9 which supports a precision guide boss 10 and which is provided at the end of the oblique wall 9 Another precision guide boss 11 is provided.

[0024] In the cavity defined by the walls 8, 9, a prismatic support 12 is arranged.

[0025] On its top side, the bracket 12 rests on the precision guide boss 10 , while on its bottom side it rests on the precision guide boss 11 .

[0026] For example by means of a ball recirculating screw 40 and a cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com