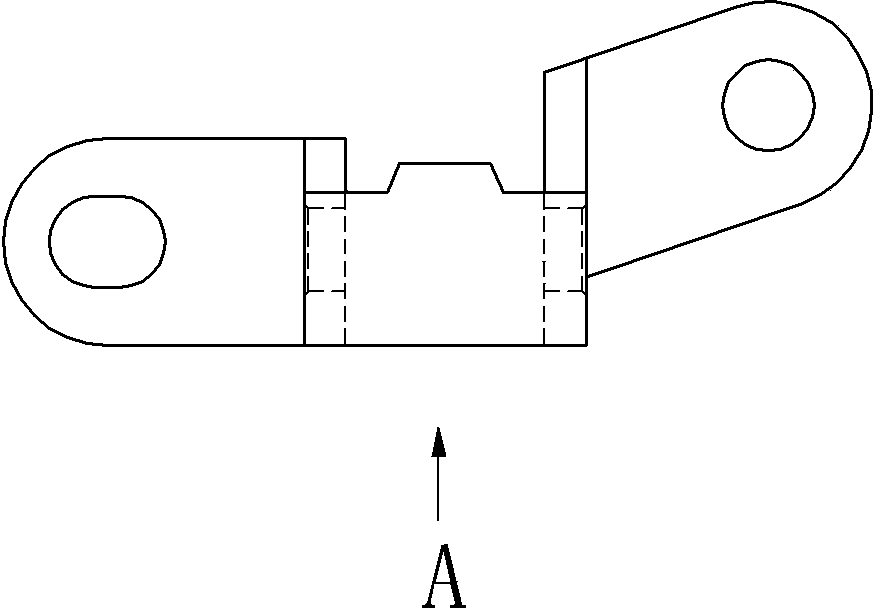

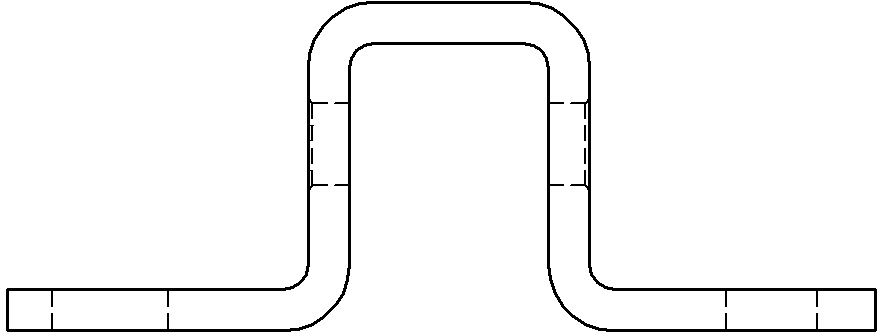

Bending and shaping die for automobile upper door hinge brackets

A technology for bending and forming, automobile doors, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problem of inaccurate positioning of workpieces, and achieve the effect of ensuring reliable positioning and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

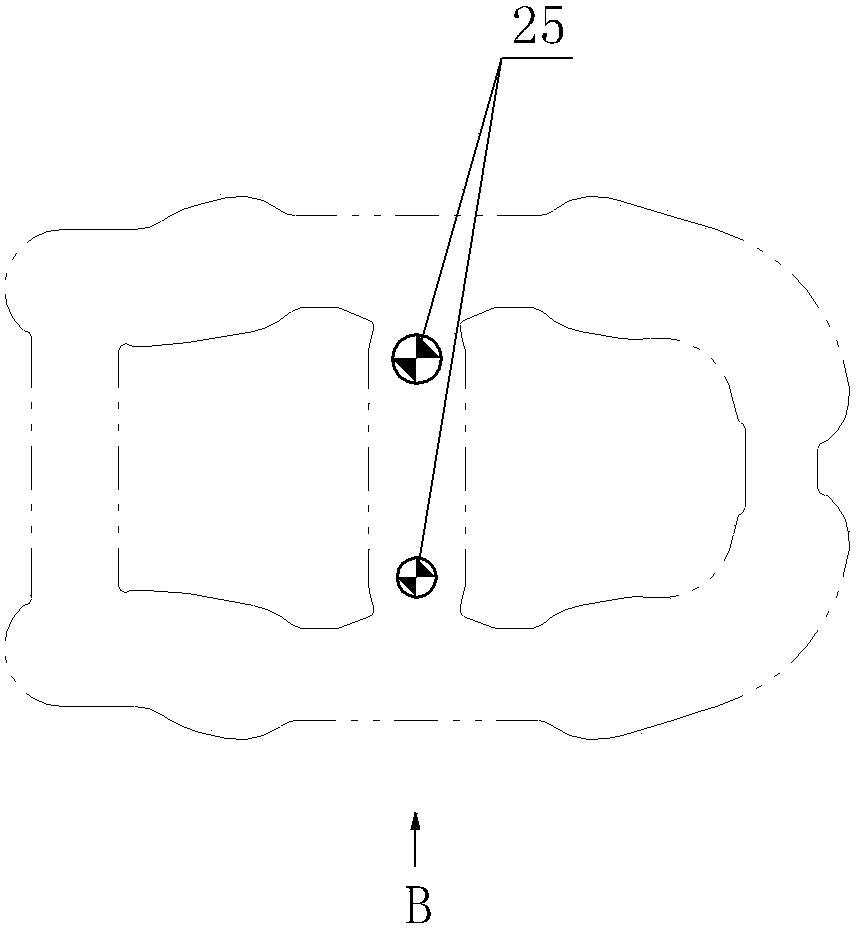

[0018] See Figure 5 , the mold of the present invention includes an upper mold structure and a lower mold structure, the upper mold structure includes an upper template 1, an upper backing plate 6 is installed under the upper template 1, an upper foot 5 is installed on the upper template 1, and the lower mold structure includes a lower template 2, A lower backing plate 7 is installed on the lower formwork 2, and a mounting plate 4 is installed under the lower formwork 2 through the lower feet 3, and the upper formwork 1 and the lower formwork 2 are guided by a sliding guide column assembly 17 for mold clamping. It is characterized in that: the upper cushion A forming punch is installed under the plate 6, a die frame 8 is installed on the lower backing plate 7, a top block 9 is inlaid in the die frame 8, and a positioning nail 14 is vertically installed in the top block 9, and the positioning nail 14 is from bottom to bottom. The top passes through the top block 9, and an ejec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com