Full-automatic plate bending machine and control method thereof

A plate rolling machine, fully automatic technology, applied in the direction of digital control, electrical program control, manufacturing tools, etc., can solve the problems of low production efficiency, high labor intensity, affecting production efficiency, etc., to improve production efficiency, reduce labor intensity, The effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

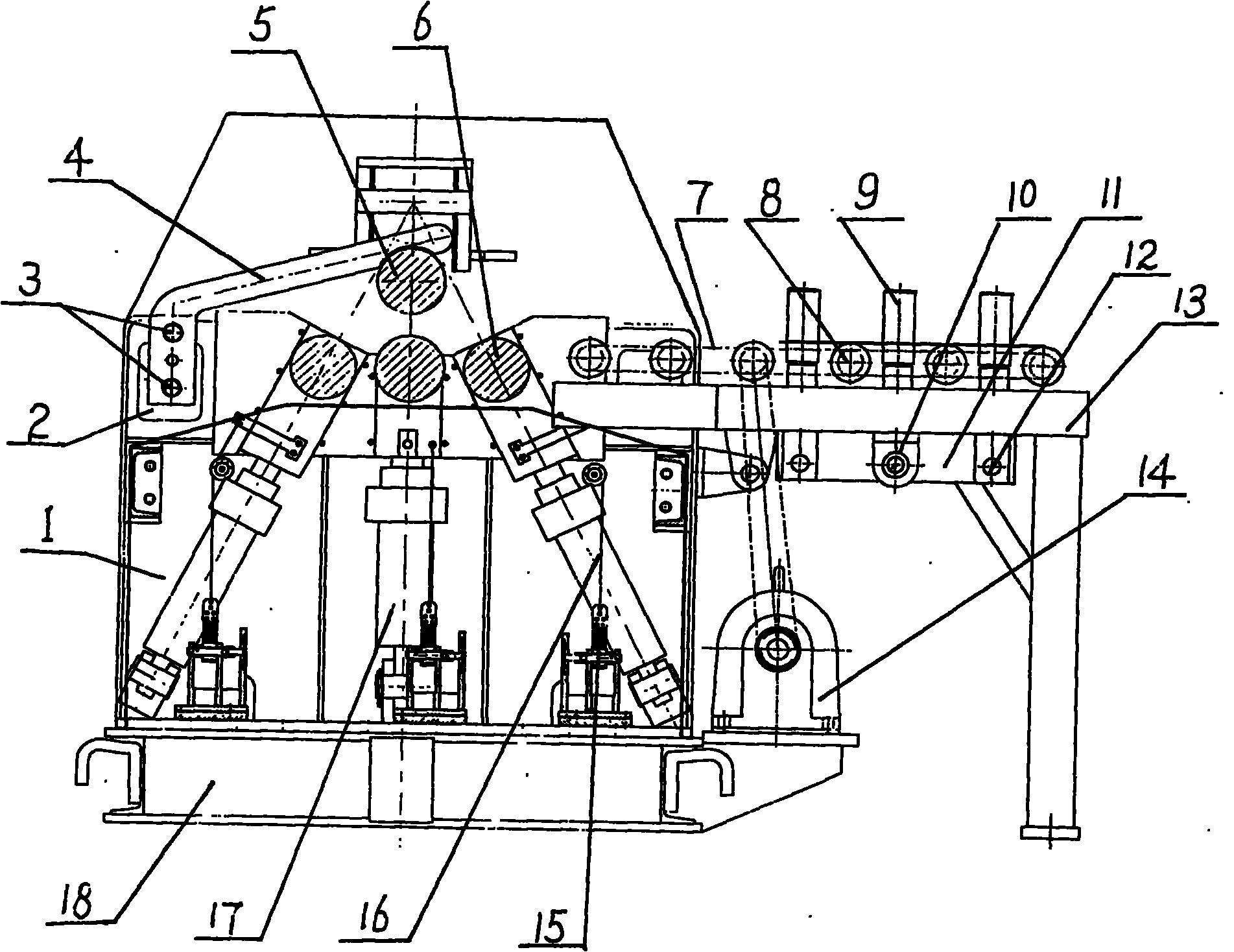

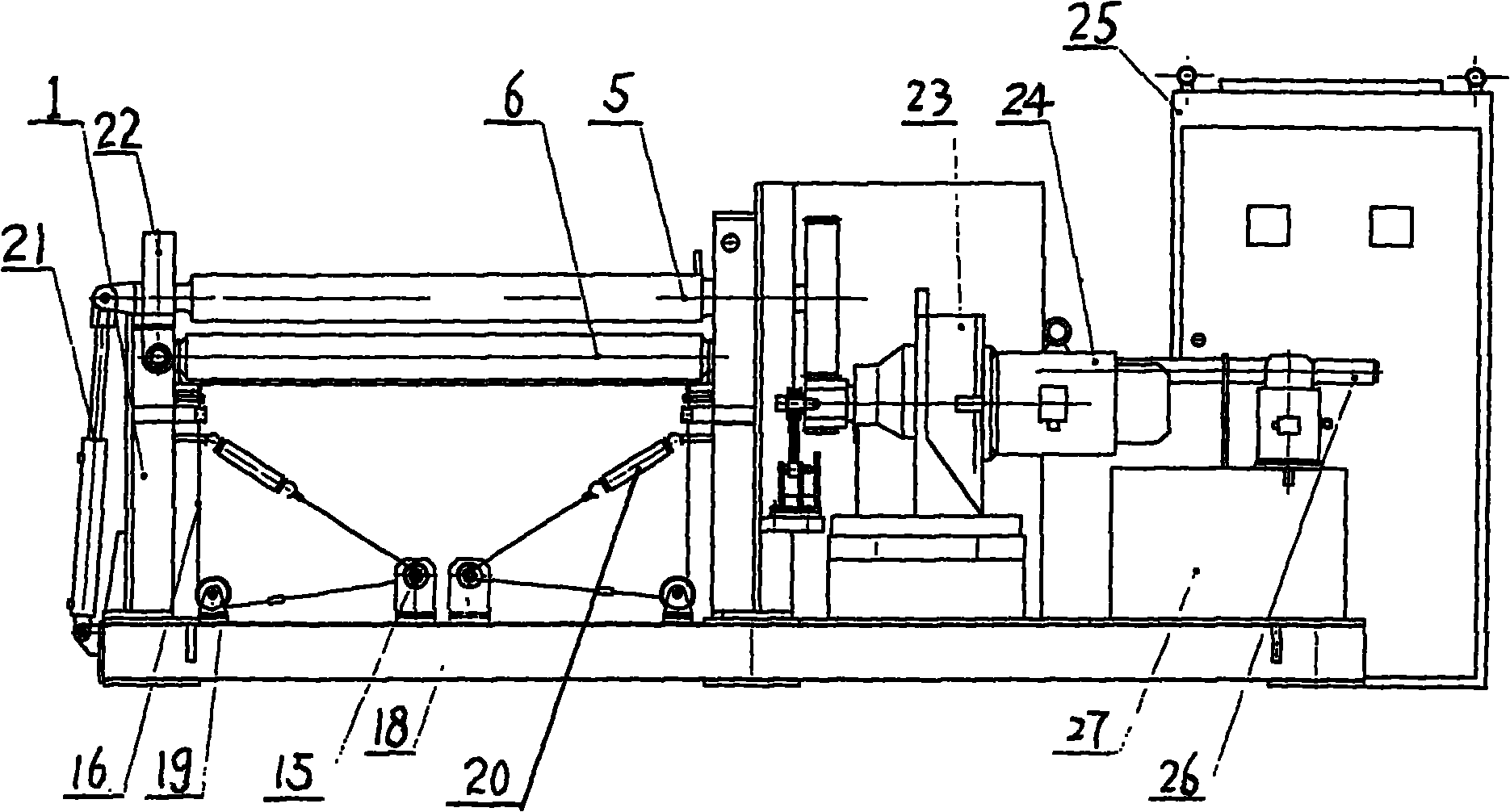

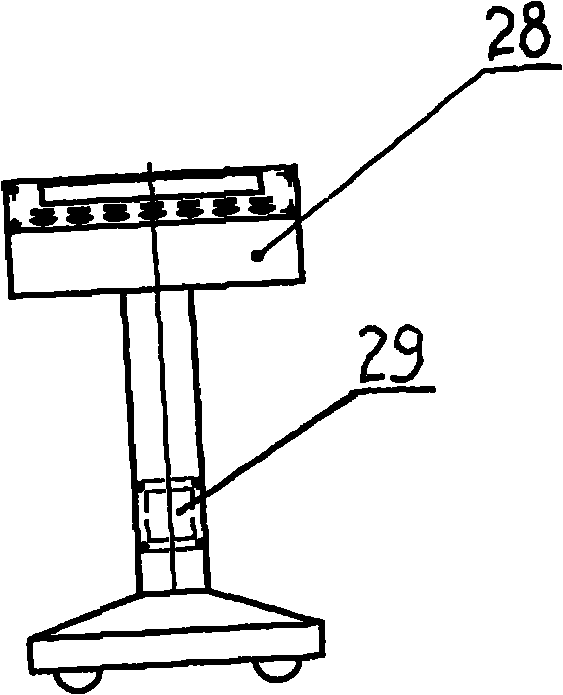

[0046] see figure 1 , figure 2 , image 3 , the labels in the figure are: machine body 1, support 2, feeding guide rod 3, material shifting arm 4, fixed driving roller 5, movable passive roller 6, chain transmission part 7, feeding roller 8, feeding righting clamping column 9. Telescopic hydraulic cylinder 10, sliding seat 11, guide rod 12, bracket 13, feeding motor 14, photoelectric encoder 15, pull wire 16, lifting hydraulic cylinder 17, bottom beam 18, fixed pulley 19, tension spring 20, movable shaft Seat opening and closing hydraulic cylinder 21, rolling roller movable shaft seat 22, reducer 23, hydraulic motor 24, electric control cabinet 25, blanking hydraulic cylinder or cylinder 26, hydraulic pump station 27, touch display 28, programmable controller PLC29.

[0047]The fully automatic plate rolling machine of the present invention includes a machine body 1, a main motor or a hydraulic motor 24, a reducer 23, a fixed driving roller 5, 3 movable passive rollers 6, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com