Multi-procedure punching compound die

A composite mold, multi-process technology, applied in the field of stamping composite molds, can solve the problems of low production efficiency, increased manufacturing difficulty, and difficulty in guaranteeing the size of the workpiece, and achieve the effects of high production efficiency and quality, and easy mold operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

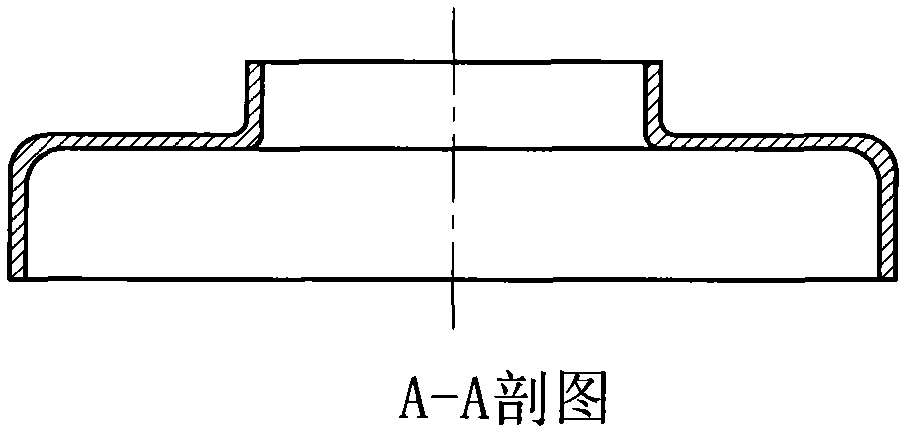

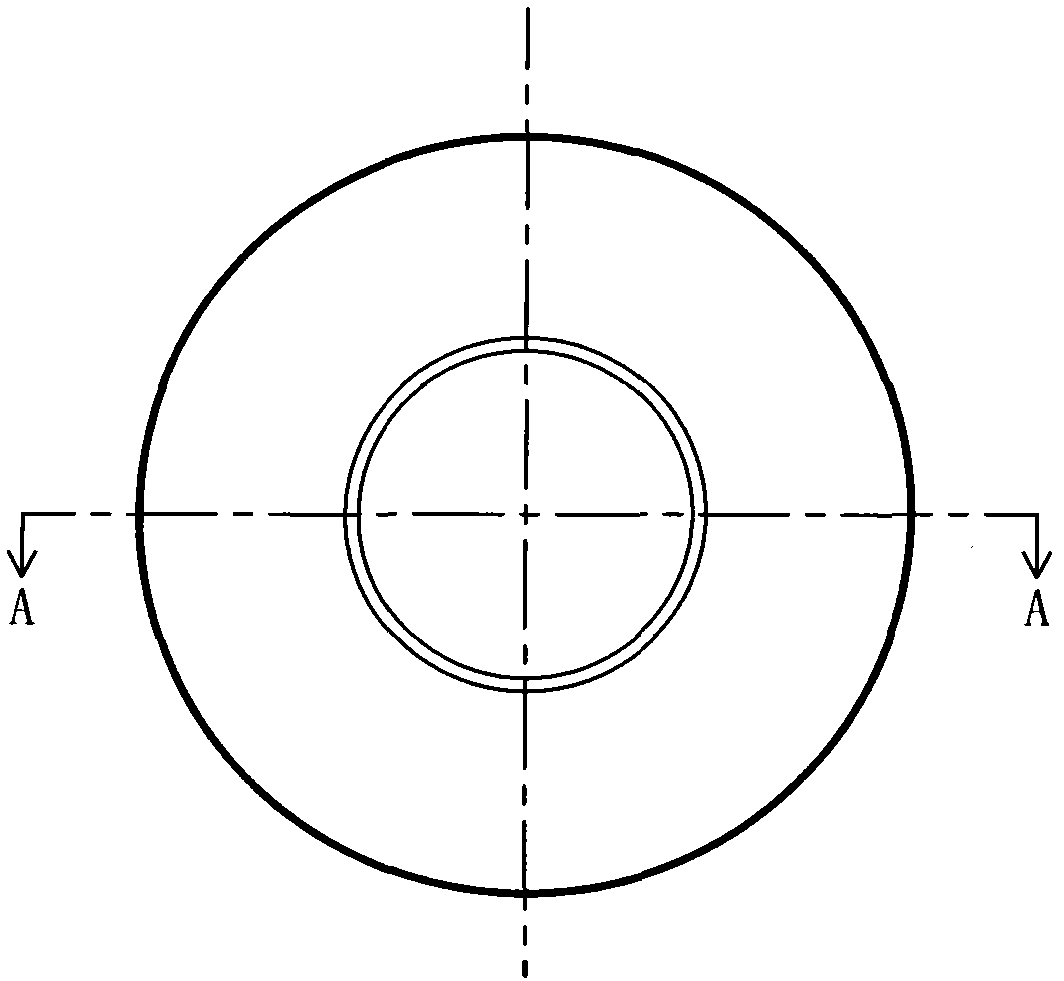

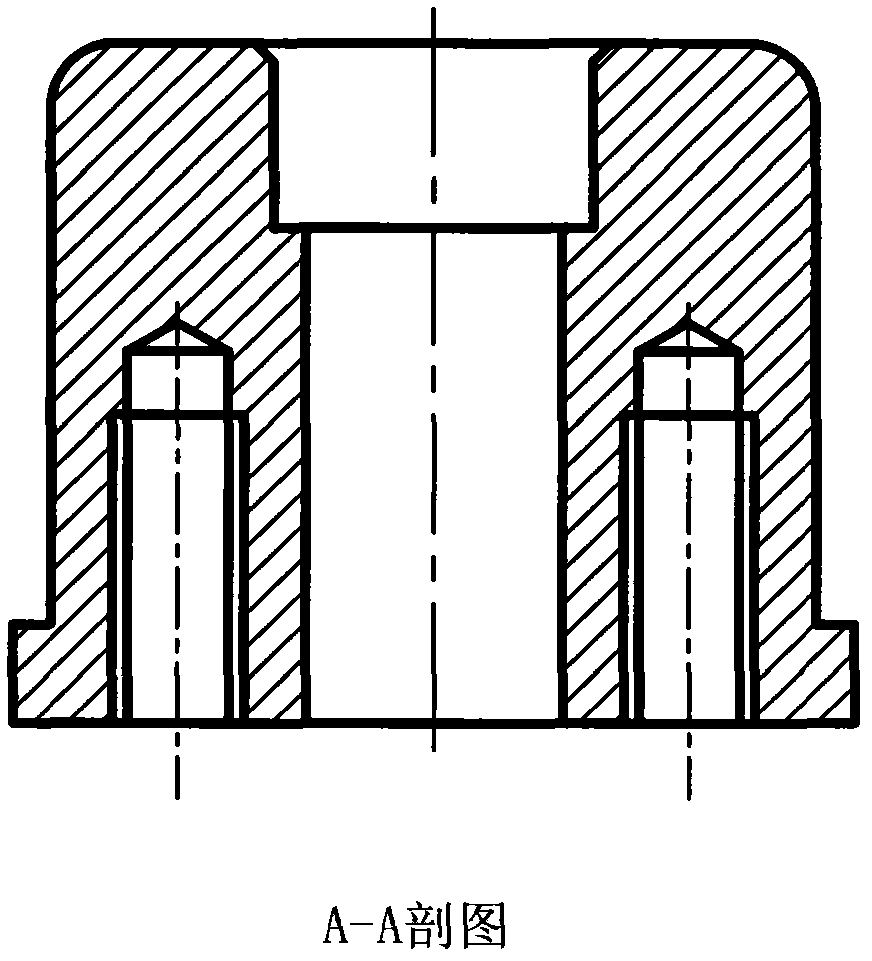

[0039] Embodiment 1, the mold of the present invention is described in detail by taking a flangeless cylindrical rotary drawing part as an example.

[0040] The material of this part is suitable for deep drawing with 08F cold-rolled thin steel plate. The thickness is 1.5mm. It can be seen from the drawings that the shape is simple and symmetrical. The diameter tolerance of the two circular openings is relatively large. There are no special requirements for tolerance and workpiece thickness. The part is designed as a hollow shell with a diameter of 60. The production process of the workpiece is determined as: blanking, punching, deep drawing, and flanging. The four processes are completed in one mold at a time.

[0041]A multi-process stamping composite mold, mainly composed of an upper mold part and a lower mold part, the upper mold part includes a limit post 2, a guide post 3, a guide sleeve 4, an upper die seat 5, a discharge plate 6, a spring 7. Cylindrical pin 8, pushing b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com