Flexible plate punching machine manipulator

A technology of manipulators and flexible boards, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve problems such as safety hazards, fatigue, and defects, and achieve the effects of preventing safety accidents, ensuring movement accuracy, and avoiding troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

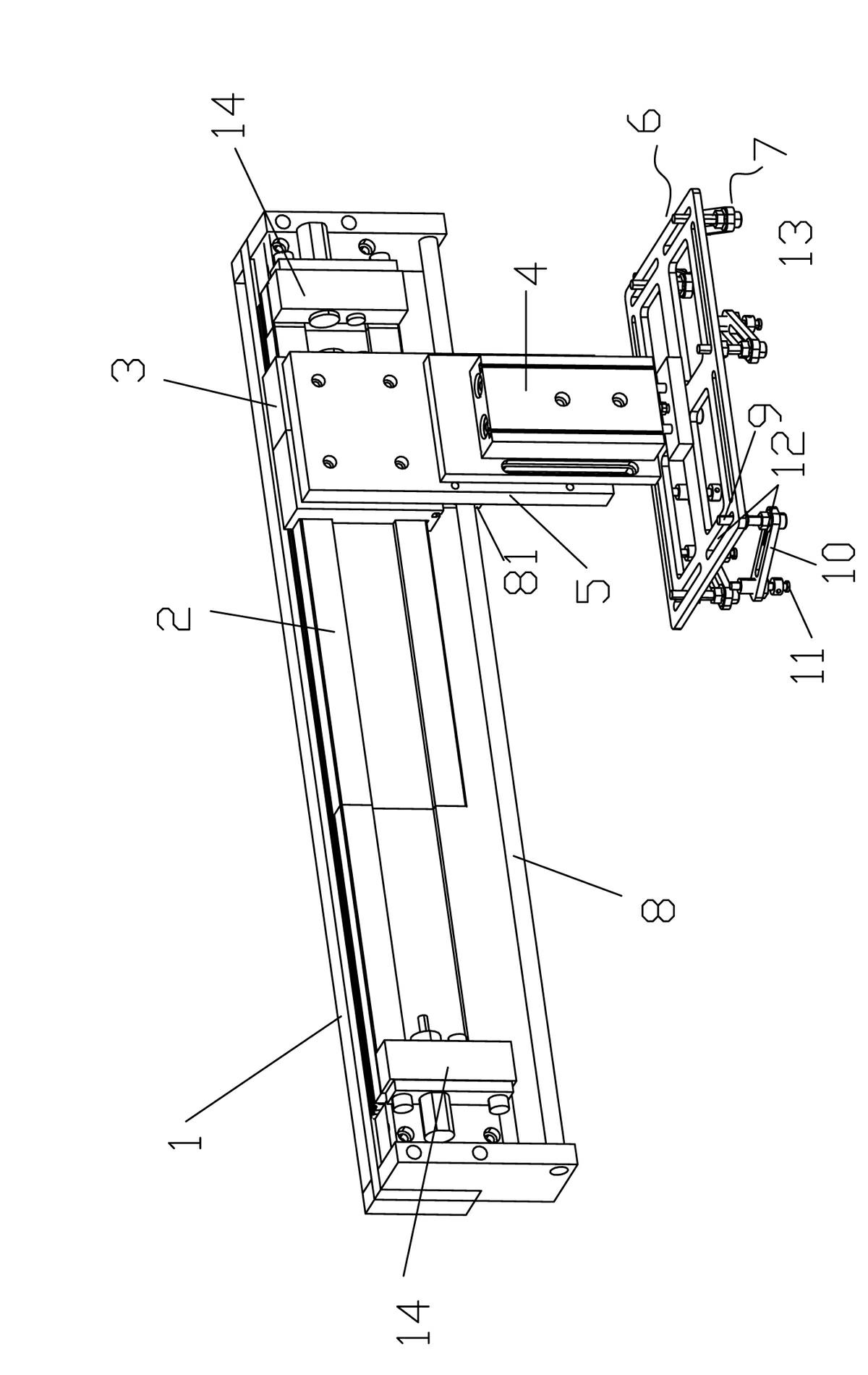

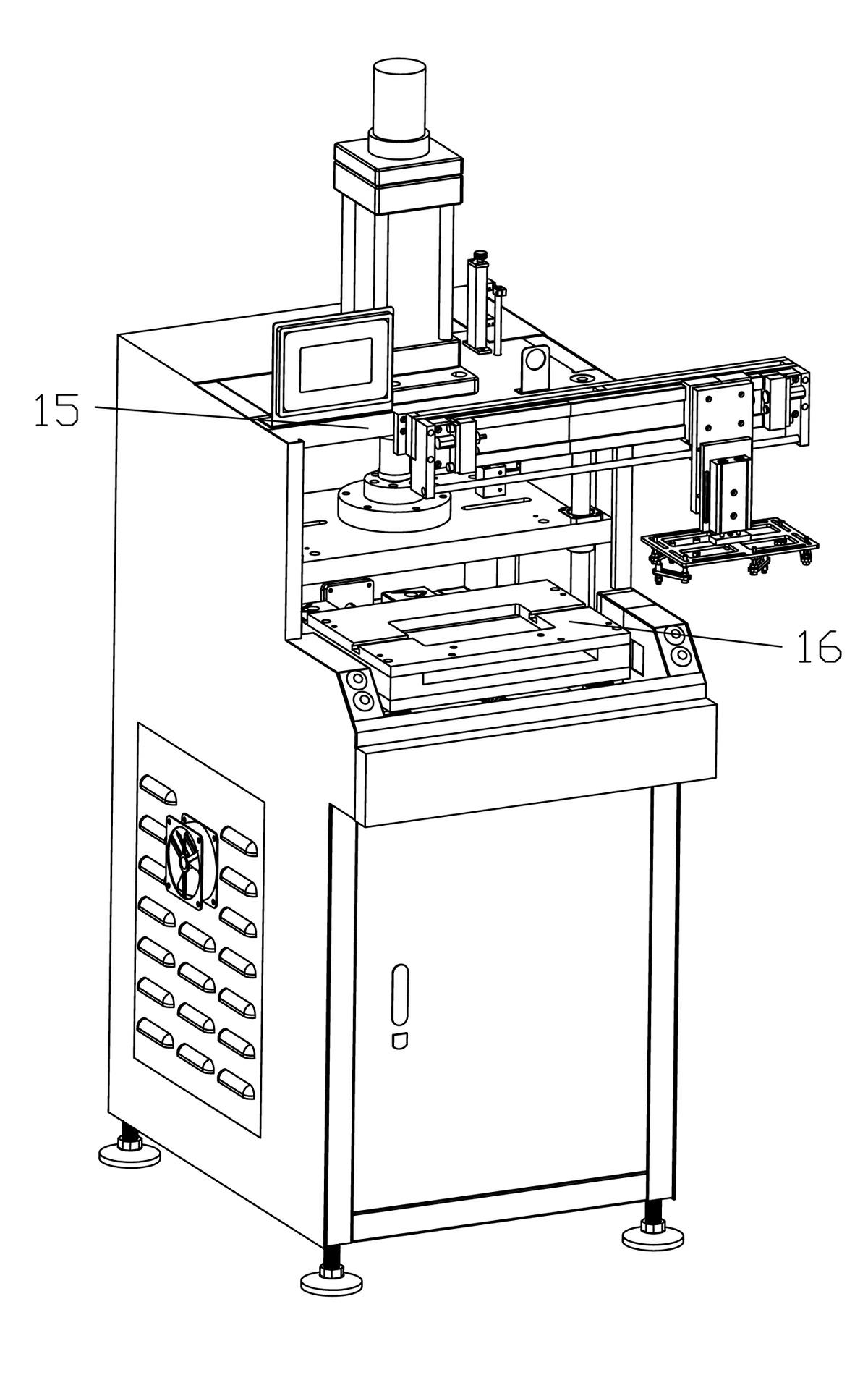

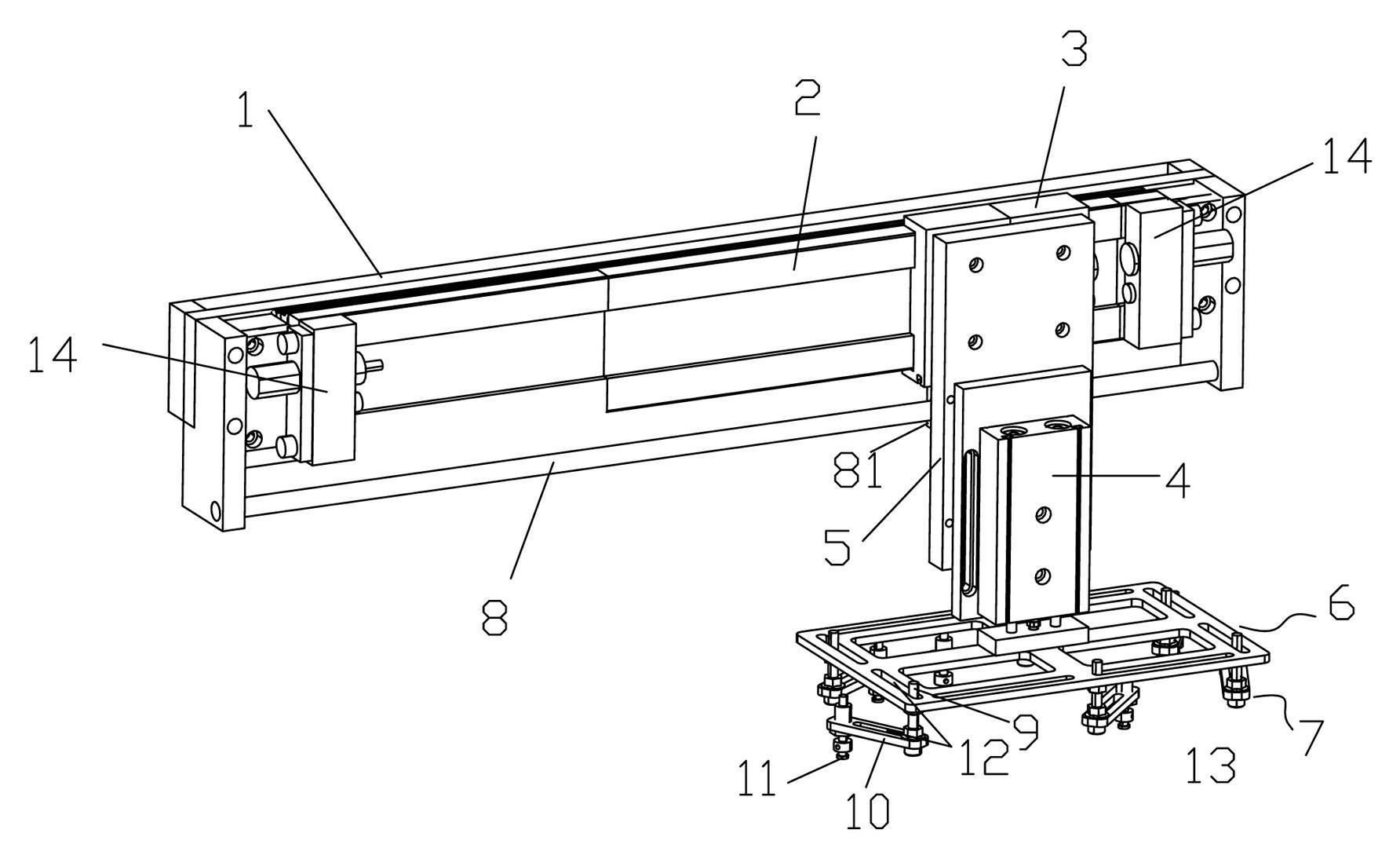

[0014] refer to figure 1 , a flexible plate punching machine manipulator of the present invention, comprising a mounting seat 1, a transverse guide rail 2, a slide table 3, a lifting and discharging cylinder 4, a cylinder mounting plate 5, a nozzle fixing plate 6 and a number of nozzle parts 7, and the transverse guide rail 2 is fixed on the mounting base 1, the sliding table 3 is set on the horizontal guide rail 2, the sliding table driving part 7 that can drive the sliding table 3 to move along the horizontal guide rail 2 is installed on the mounting base 1, and the cylinder mounting plate 5 is fixed on the sliding table 3 Above, the lifting and discharging cylinder 4 is installed on the cylinder mounting plate 5, the suction nozzle fixed plate 6 is arranged under the lifting and discharging cylinder 4 and connected with the driving end of the lifting and discharging cylinder 4, and the suction nozzle parts 7 are distributed on the suction nozzle fixed Plate 6. In an actual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com