Linear reciprocating motor

A linear reciprocating, motor stator technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of reduced mechanical efficiency, high production costs, and many transmission links, so as to improve mechanical efficiency, reduce production costs, and reduce transmission link effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail below in conjunction with accompanying drawing:

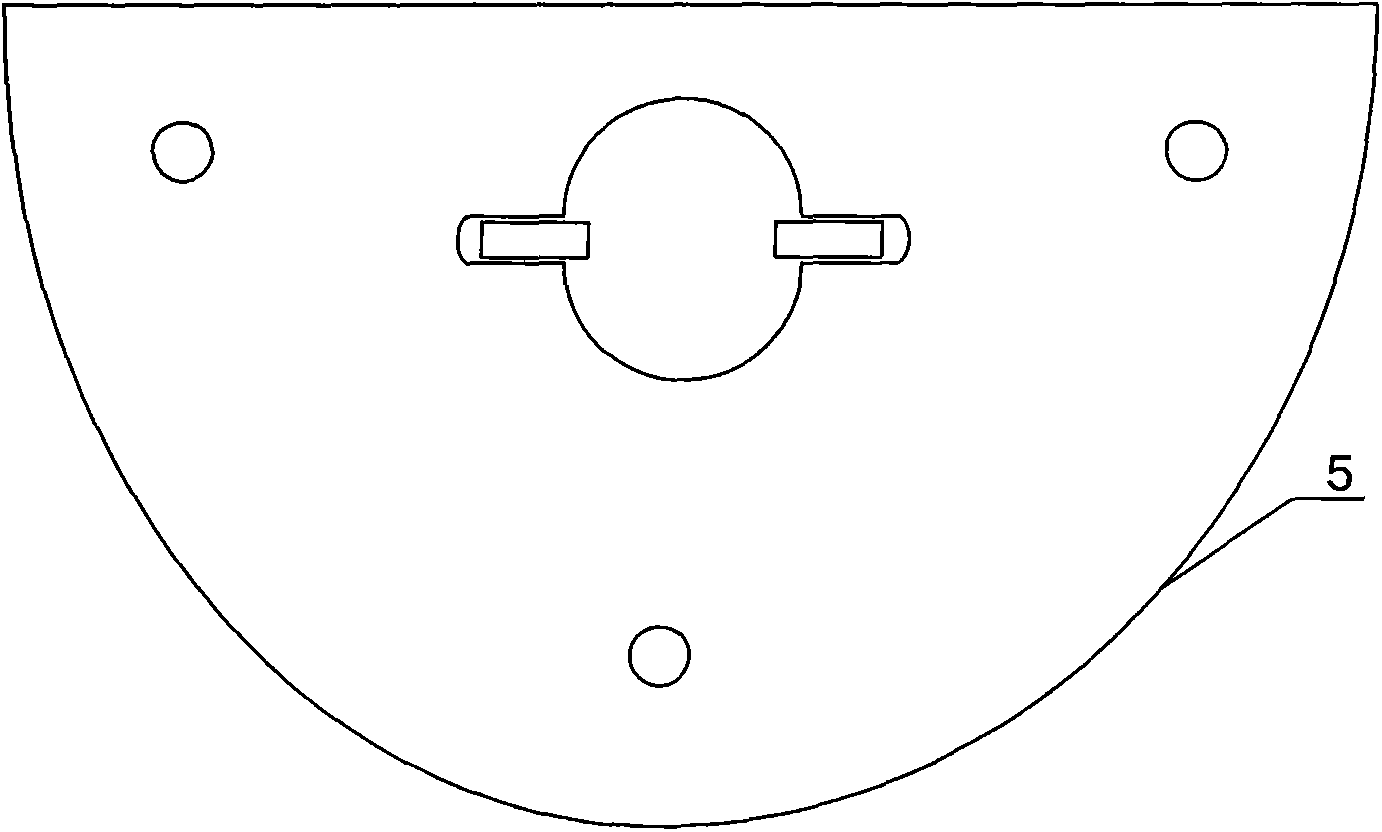

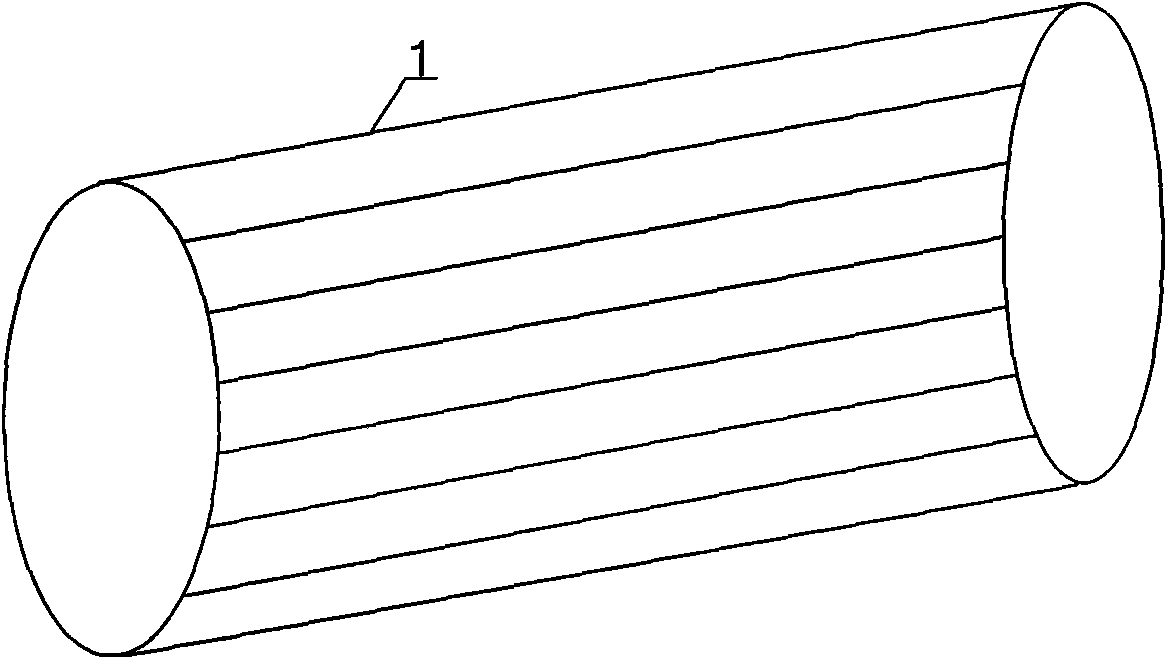

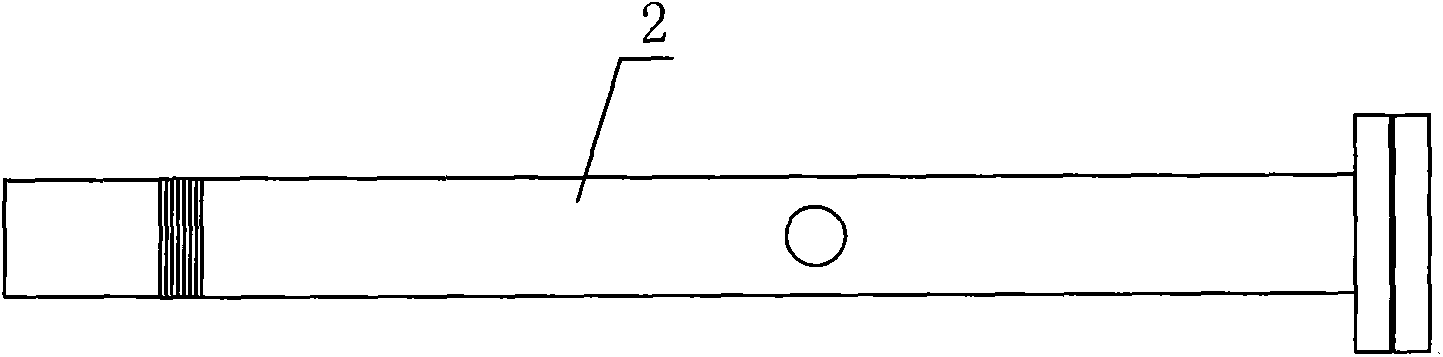

[0019] see Figure 1 to Figure 6 , a linear reciprocating motor, including a reciprocating screw rod 4, the reciprocating screw rod 4 is covered with a hollow shaft 2 with a circular hole in the side wall, and the guide block 3 is placed in the circular small hole of the hollow shaft and connected with the reciprocating wire The two-way chute of the rod 4 is in contact, and the outer side of the hollow shaft 2 on which the guide block 3 is installed is covered with a rotor 1, and the rotor 1 is covered with a motor stator.

[0020] see Figure 4 The guide block 3 includes a guide handle with a round top and a guide slider arranged below the guide handle, and the shape of the contact end of the guide slider and the two-way chute of the reciprocating screw rod 1 is crescent-shaped.

[0021] The sidewalls at the two ends of the reciprocating screw mandrel 4 are symmetri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com