High-voltage circuit breaker device

A circuit breaker and high-voltage technology, which is applied in high-voltage air circuit breakers, high-voltage/high-current switches, circuits, etc., can solve the problems of inability to effectively maintain the high vacuum of the arc extinguishing chamber, unfavorable circuit breaking, and high cost. The process is simple and easy, which is conducive to circuit breaking and ensures the effect of high vacuum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

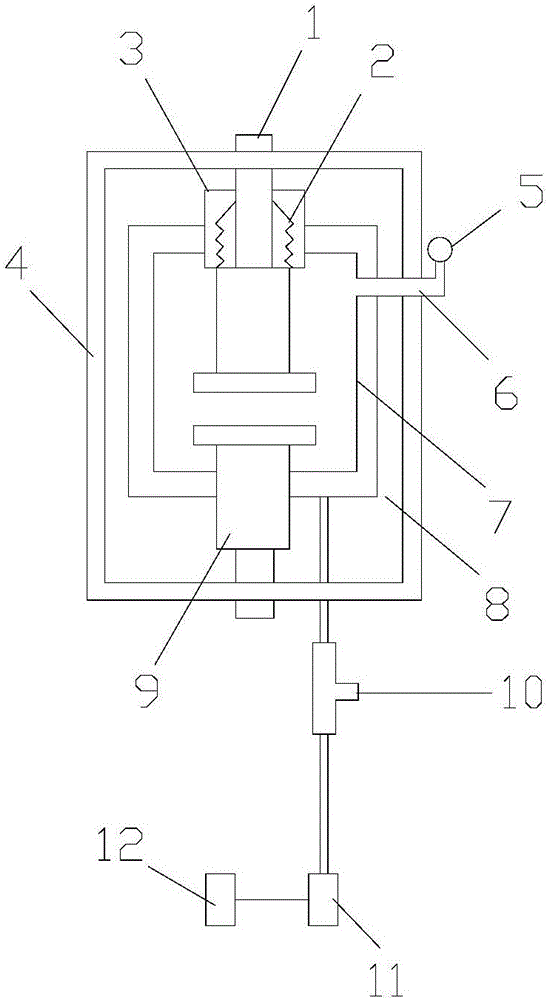

[0017] Referring to 1, a high-voltage circuit breaker includes an insulating case 4, a movable conductive rod 1, a fixed conductive rod 9, a first vacuum cover 8, a second vacuum cover 7, and a pressure measurement mechanism. The movable conductive rod 1 and the fixed conductive rod One end of the conductive rod 9 is respectively located in the first vacuum cover 7, and the other ends of the movable conductive rod 1 and the fixed conductive rod 9 respectively extend to the outside of the first vacuum cover 8, and the first vacuum cover 8 is also provided with a second Two vacuum covers 7, the side wall of the second vacuum cover 7 communicates with a glass tube 6, the glass tube 6 extends to the outside of the first vacuum cover 8, the end of the glass tube 6 is provided with a pressure measuring mechanism, the second An insulating shell 4 is arranged on the outside of a vacuum cover 8, and the second vacuum cover 7 is connected with a crank arm 10, and the crank arm 10 is conn...

Embodiment 2

[0026] Referring to 1, a high-voltage circuit breaker includes an insulating case 4, a movable conductive rod 1, a fixed conductive rod 9, a first vacuum cover 8, a second vacuum cover 7, and a pressure measurement mechanism. The movable conductive rod 1 and the fixed conductive rod One end of the conductive rod 9 is respectively located in the first vacuum cover 7, and the other ends of the movable conductive rod 1 and the fixed conductive rod 9 respectively extend to the outside of the first vacuum cover 8, and the first vacuum cover 8 is also provided with a second Two vacuum covers 7, the side wall of the second vacuum cover 7 communicates with a glass tube 6, the glass tube 6 extends to the outside of the first vacuum cover 8, the end of the glass tube 6 is provided with a pressure measuring mechanism, the first An insulating shell 4 is arranged on the outside of a vacuum cover 8, and the second vacuum cover 7 is connected with a crank arm 10, and the crank arm 10 is conne...

Embodiment 3

[0035] Referring to 1, a high-voltage circuit breaker includes an insulating case 4, a movable conductive rod 1, a fixed conductive rod 9, a first vacuum cover 8, a second vacuum cover 7, and a pressure measurement mechanism. The movable conductive rod 1 and the fixed conductive rod One end of the conductive rod 9 is respectively located in the first vacuum cover 7, and the other ends of the movable conductive rod 1 and the fixed conductive rod 9 respectively extend to the outside of the first vacuum cover 8, and the first vacuum cover 8 is also provided with a second Two vacuum covers 7, the side wall of the second vacuum cover 7 communicates with a glass tube 6, the glass tube 6 extends to the outside of the first vacuum cover 8, the end of the glass tube 6 is provided with a pressure measuring mechanism, the first An insulating shell 4 is arranged on the outside of a vacuum cover 8, and the second vacuum cover 7 is connected with a crank arm 10, and the crank arm 10 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com