Automatic angle making device of 180-degree for grinding bent axle slotted lever neck

A crankshaft connecting rod and automatic indexing technology, which is applied in the direction of grinding workpiece supports, abrasive belt grinders, etc., can solve the problems of high price, affecting grinding efficiency, difficult to guarantee indexing accuracy and stability, and achieve simple structure, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

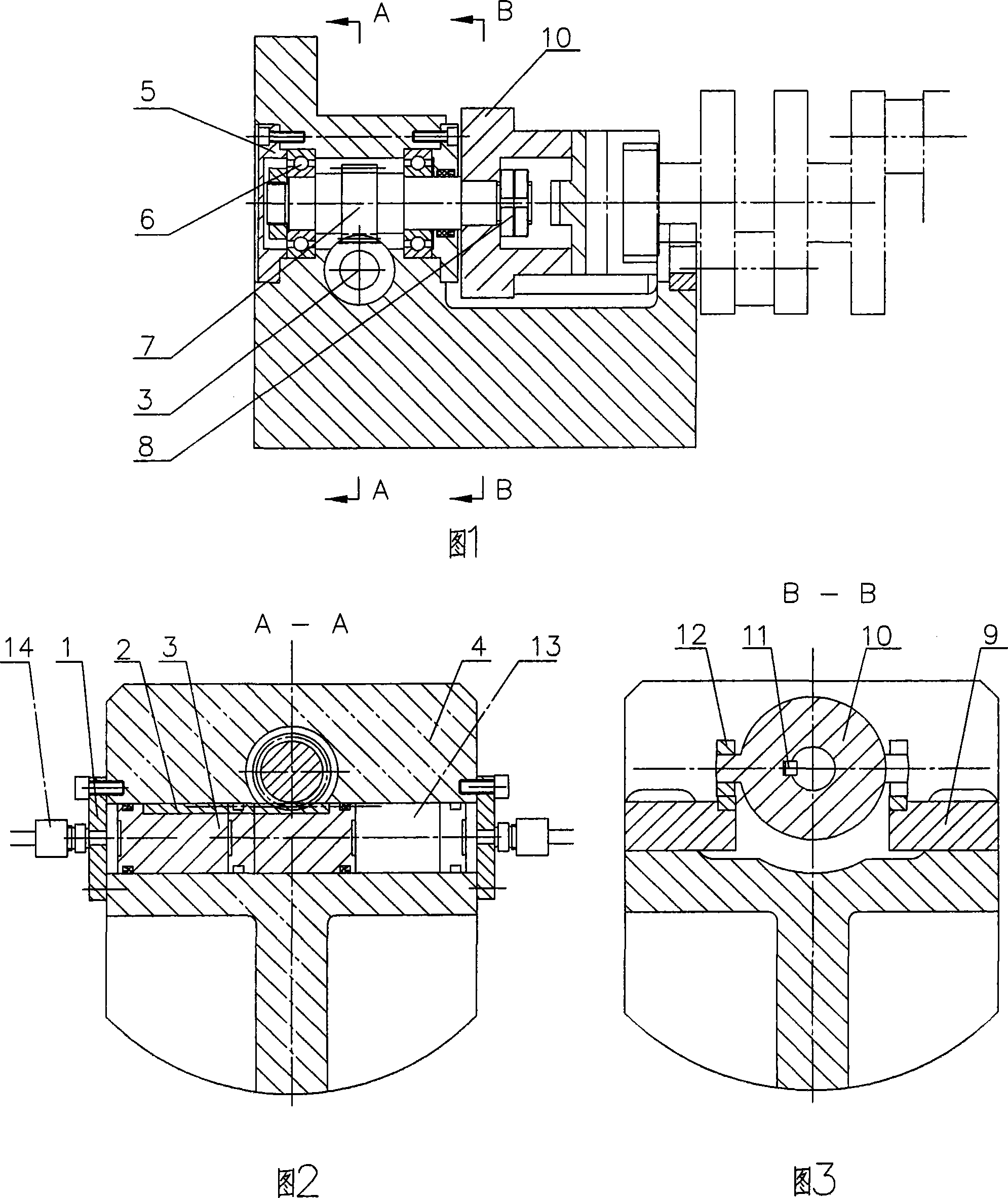

[0015] Referring to Fig. 1, Fig. 2 and Fig. 3, the gear shaft 7 is provided on the clamp body 4 through the bearing 6, and the index plate 10 is installed on the gear shaft 7 through the lock nut 8 and the key 11, and the two sides of the clamp body 4 are installed There are indexing positioning stoppers 9 and adjusting pads 12 corresponding to the indexing plate 10, an oil cylinder 13 and its piston 3 are arranged inside the clamp body 4, and an oil cylinder gland 1 and a hydraulic oil pipe 14 are arranged at both ends of the oil cylinder 13, and the piston 3 is located between the two oil cylinder glands 1 in the oil cylinder 13, and the piston 3 is provided with a toothed rack 2 meshing with the pinion shaft 7 for transmission.

[0016] Referring to Fig. 1, Fig. 2 and Fig. 3, the present invention uses the structural principles of gears and racks, hydraulic oil drives the piston 3 to move left and right in the oil cylinder 13 through the hydraulic oil pipe 14 on the cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com