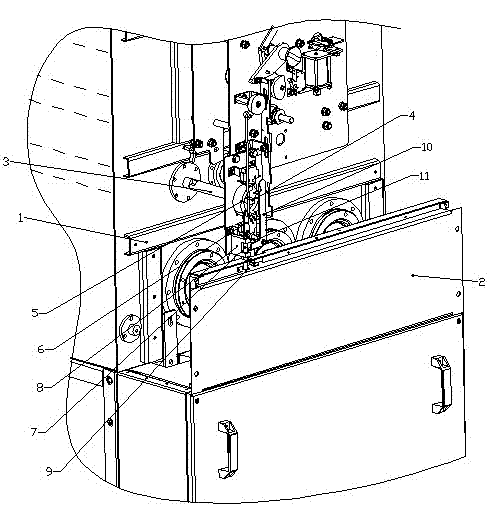

Switch cabinet grounding switch and lower door interlocking mechanism

A grounding switch and switchgear technology, applied in the field of switchgear grounding switch and lower door interlocking mechanism, can solve the problems of unsatisfactory operation requirements, poor interlocking reliability, complex structure, etc., and achieve simple structure and high operation reliability , the effect of fewer transmission links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

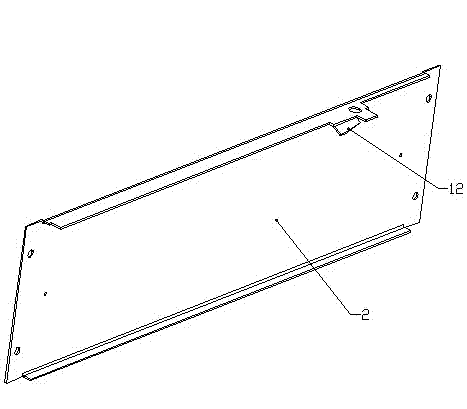

[0009] As shown in the figure, the interlock mechanism between the grounding switch and the lower door of the switchgear includes a cabinet body 1 of the switchgear body, a grounding switch is installed in the middle of the cabinet body, a fuse room is arranged at the lower part of the cabinet body, and a lower door 2 is arranged at the front end of the fuse room The operating shaft 3 of the grounding switch is arranged vertically and horizontally, and the front end of the operating shaft is a shaft head 4 that can be plugged and matched with the operating handle; the shaft head is located above the top frame of the lower door 2, and the shaft head 4 is connected to a The interlocking disc 5 that can rotate with the shaft head has a connecting rod 6 hinged on the edge of the interlocking disc, and the lower end of the connecting rod 6 is hinged with a lock pin 7; the lock pin 7 is vertically inserted into a guide hole on a guide seat 8 Among them, the rotation of the interlocki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com