High voltage vacuum circuit breaker

A vacuum circuit breaker, high-voltage technology, applied in high-voltage air circuit breakers, high-voltage/high-current switches, circuits, etc., can solve the problems of slow response speed, damage to vacuum tube contacts, large closing inrush current, etc., and achieve the goal of reducing force Loss, reduce friction link, reduce the effect of overvoltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

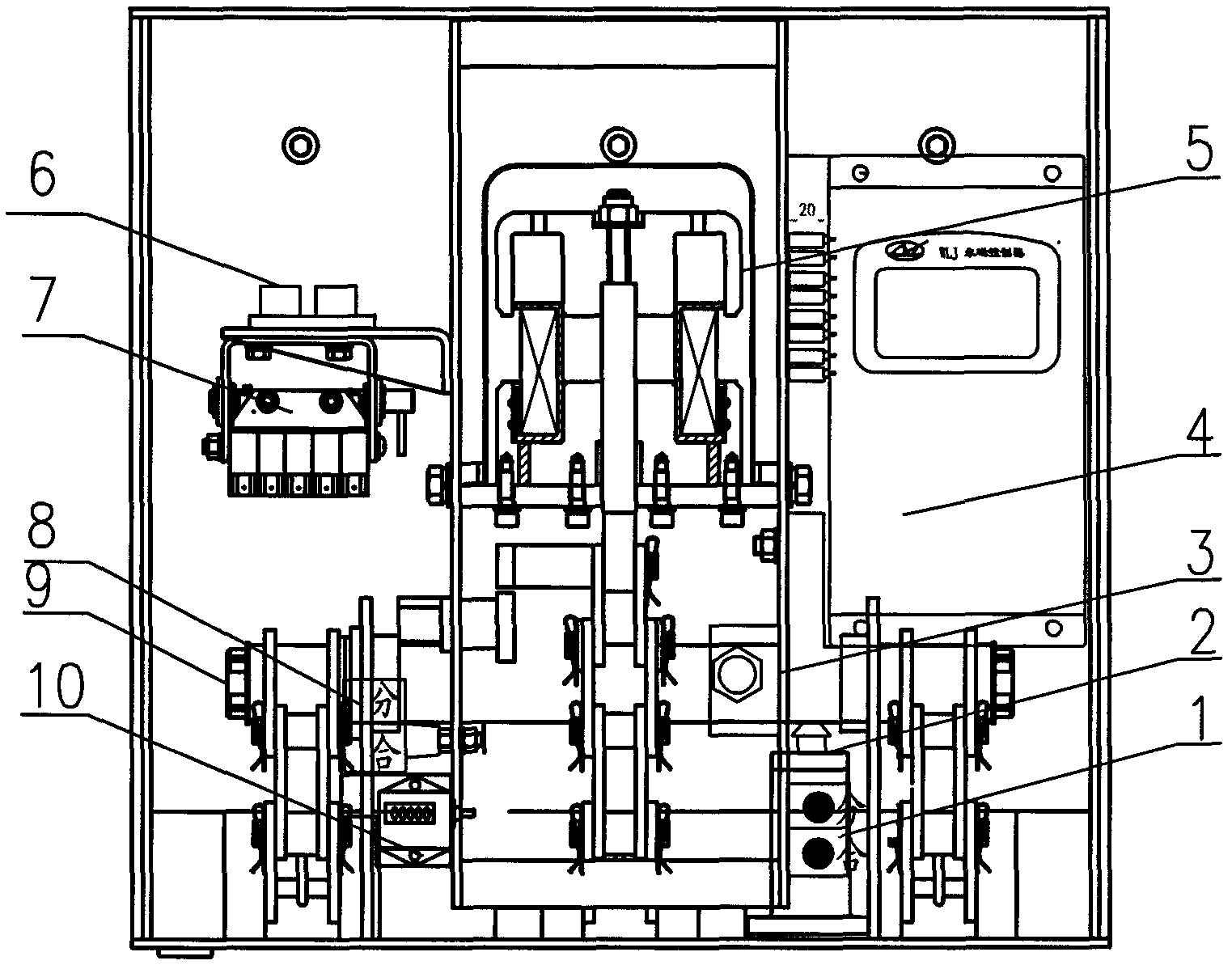

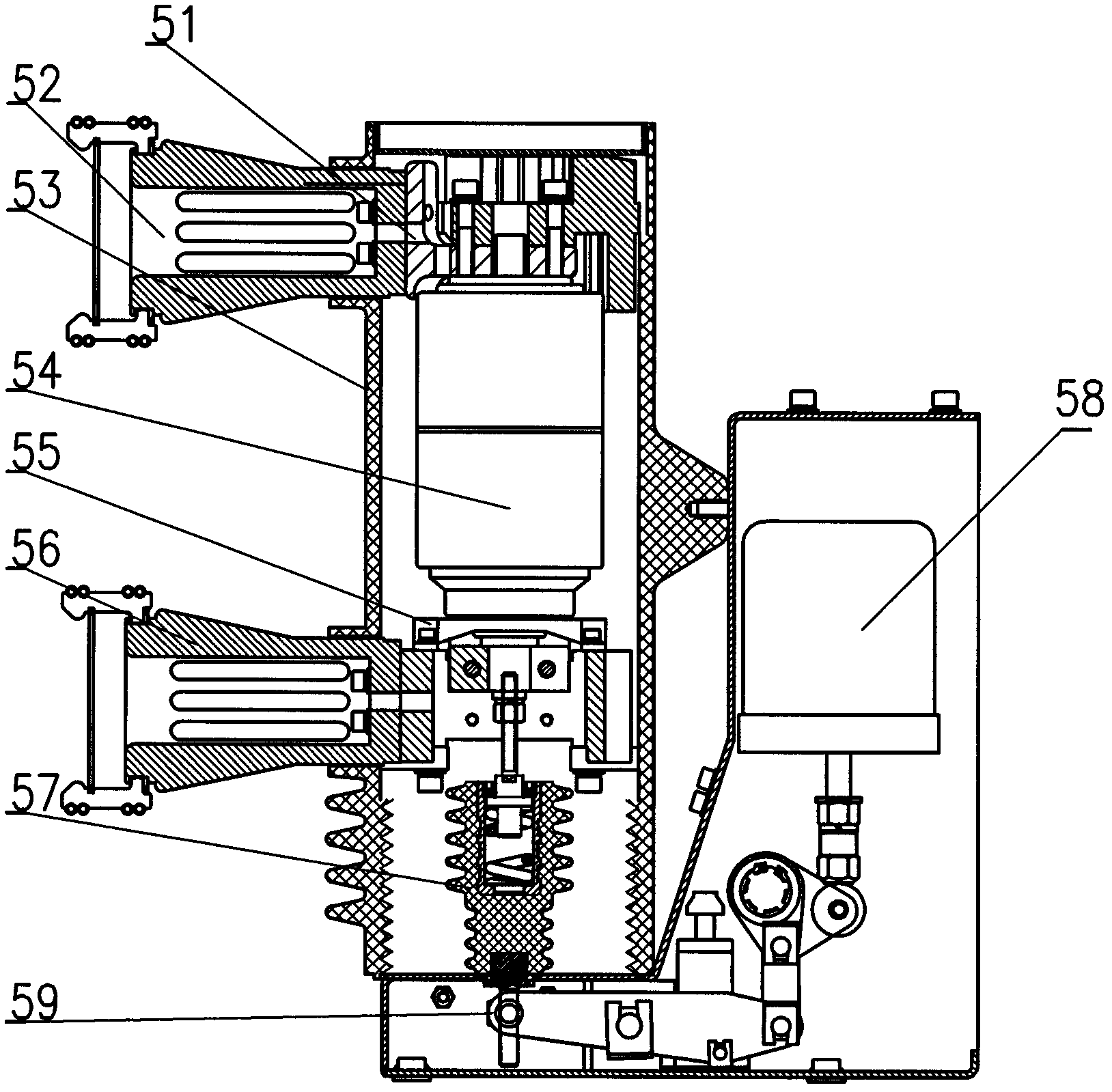

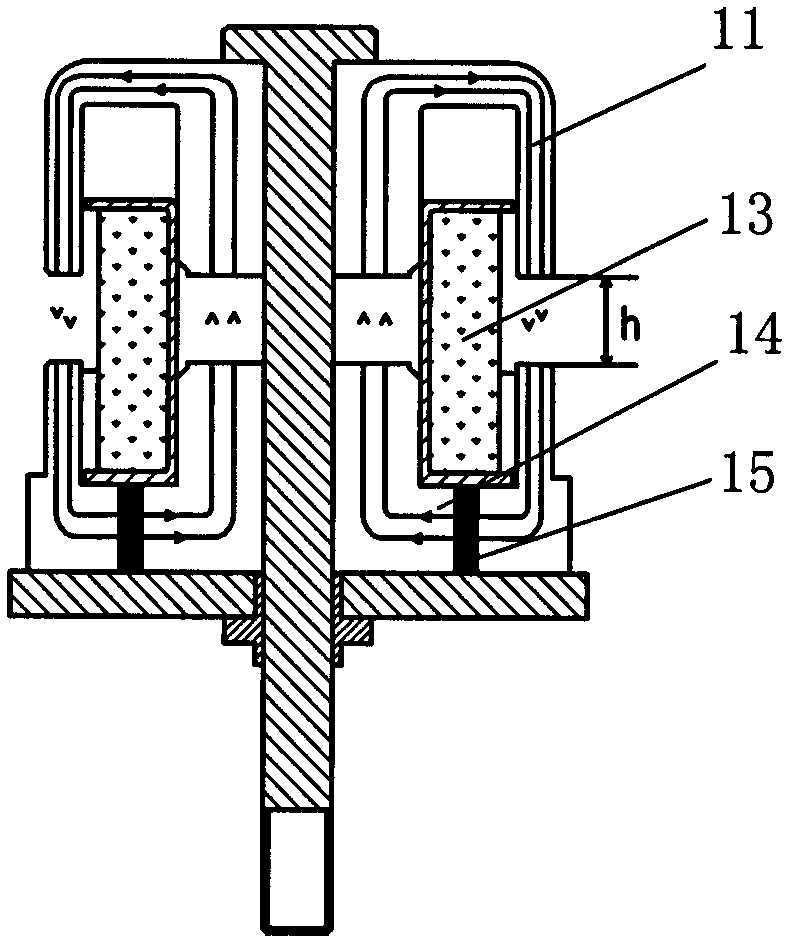

[0017] The invention provides a high-voltage vacuum circuit breaker, which includes opening and closing buttons 1, a buffer 2, an emergency opening device 3, a control mechanism 4, an operating mechanism 5, a remote opening and closing voltage dividing resistor 6, and a micro switch 7 , permanent magnet spindle 8, opening and closing sign 9, counter 10 and other components, see figure 1 As shown; wherein the operating mechanism 5 is a permanent magnet operating mechanism, which includes an upper support 51, an upper outgoing line 52, an insulating cylinder 53, a vacuum interrupter 54, a lower support 55, a lower outgoing line 56, an insulating Pull rod 57 (with contact spring inside), electromagnetic system 58 (with drive coil inside), overtravel adjustment nut 59, IGBT switch (not shown in the figure) used to drive insulating pull rod 57 to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com