Blade tip alula of turbine or steam turbine moving-blade

A turbine and steam turbine technology, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of complex flow in cascade passages, increased total loss of impeller machinery, and reduced work, so as to improve the secondary flow field and reduce The effect of small leaf tip leakage and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in further detail below in conjunction with accompanying drawing:

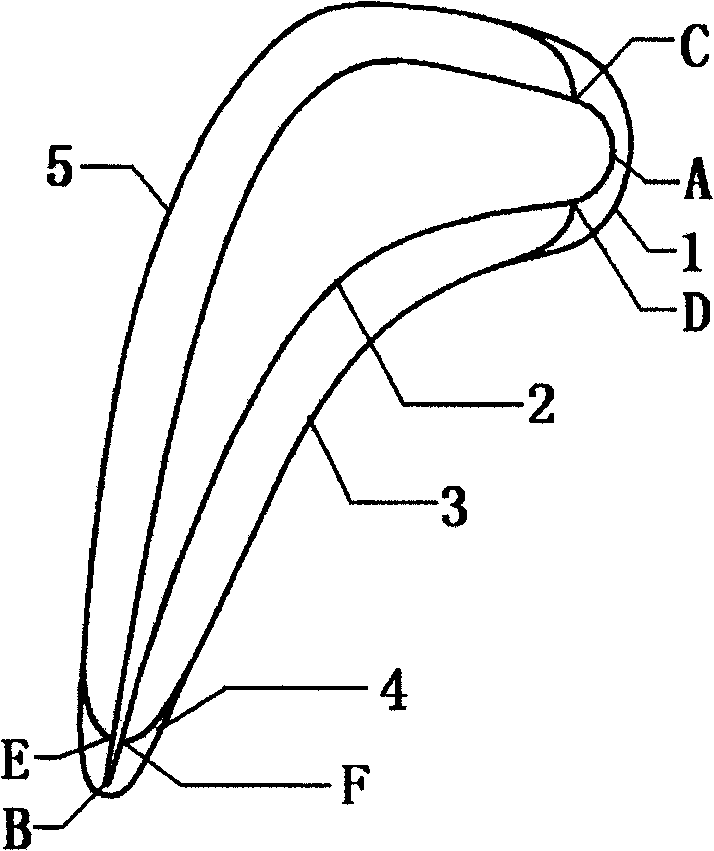

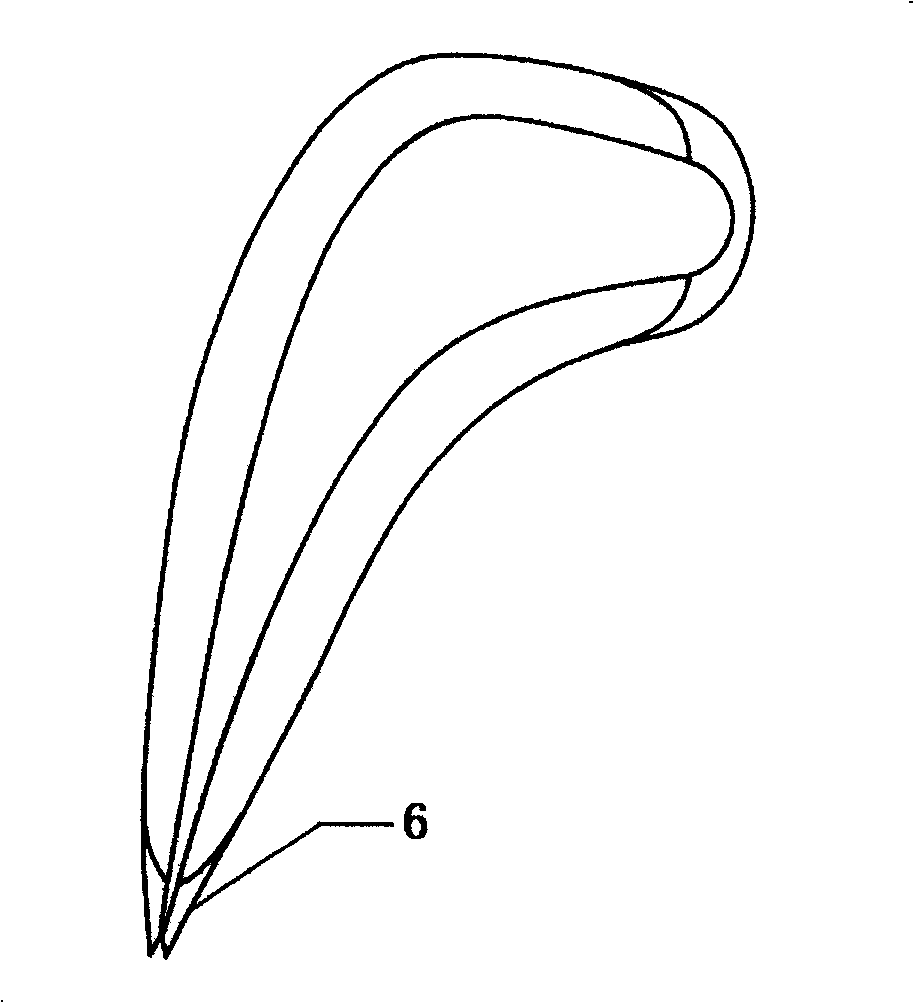

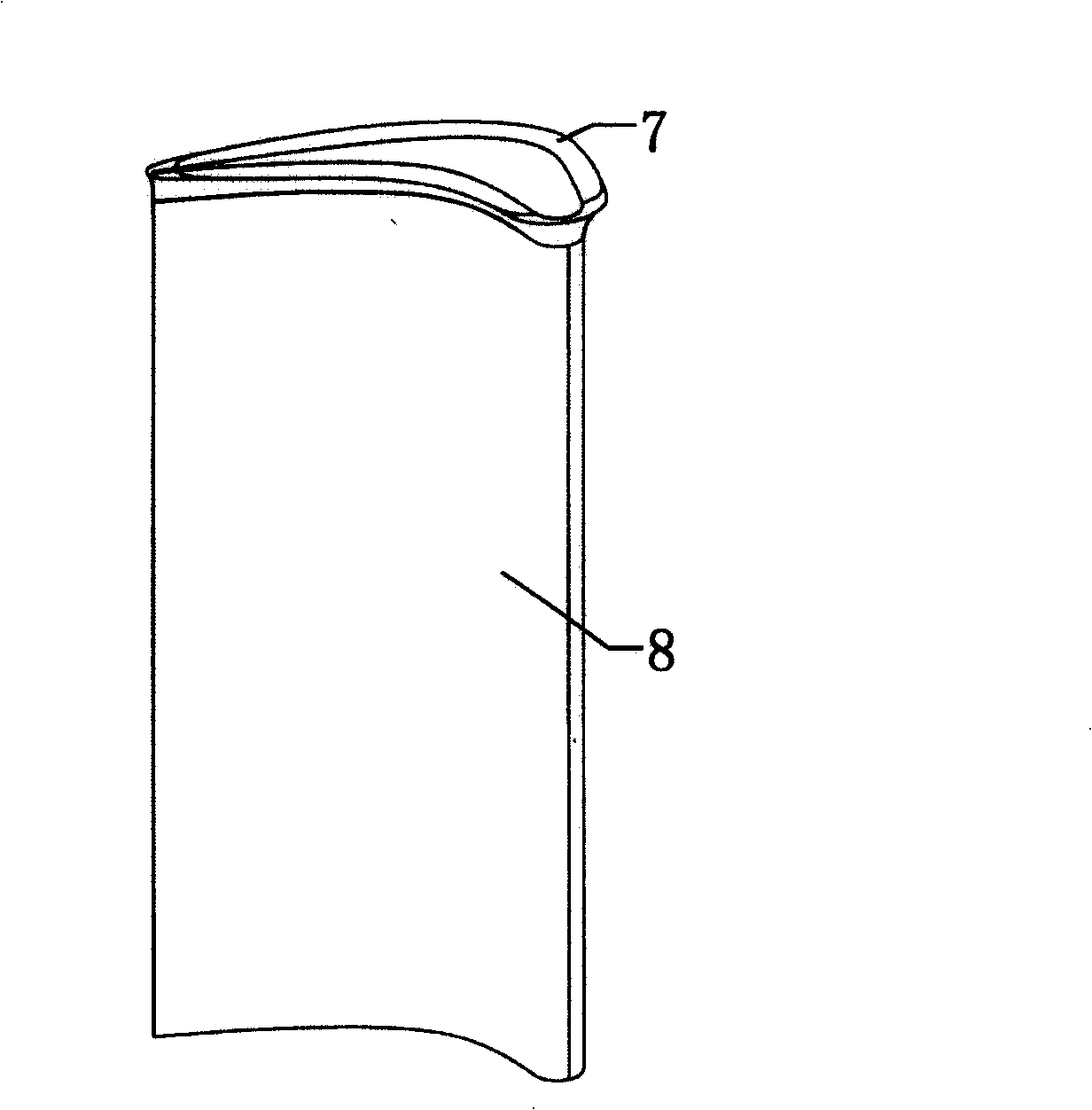

[0015] like Figure 1 to Figure 4 As shown, the turbine or steam turbine moving blade tiplet of the present invention is mainly composed of leading edge wing 1, pressure surface wing 3, suction surface wing 5 and smooth structure trailing edge wing 4 or dovetail structure trailing edge wing 6, and pressure surface wing 3 The suction surface wing 5 is a small airfoil extending in the circumferential direction between the leading edge point A and the trailing edge point B on the basis of the profile of the moving blade, and the pressure surface wing 3 and the suction surface wing 5 The leading edge point D and the leading edge point C are located between the leading edge point A of the rotor blade profile or between the leading edge point A and the maximum thickness of the blade profile, and the trailing edge point F and the trailing edge point E of the pressure surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com