Gummed paper adhering machine

A technology of adhesive tape and paper machine, applied in the direction of pile separation, non-aqueous electrolyte battery, electrochemical generator, etc., can solve the problem of inability to realize automatic cutting and pasting of adhesive tape, inaccurate length cutting of adhesive tape, waste of manpower and Material resources and other issues, to achieve the effect of saving manpower, saving time, and improving mechanical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The invention provides a fully automatic glued paper cutting and glued paper equipment.

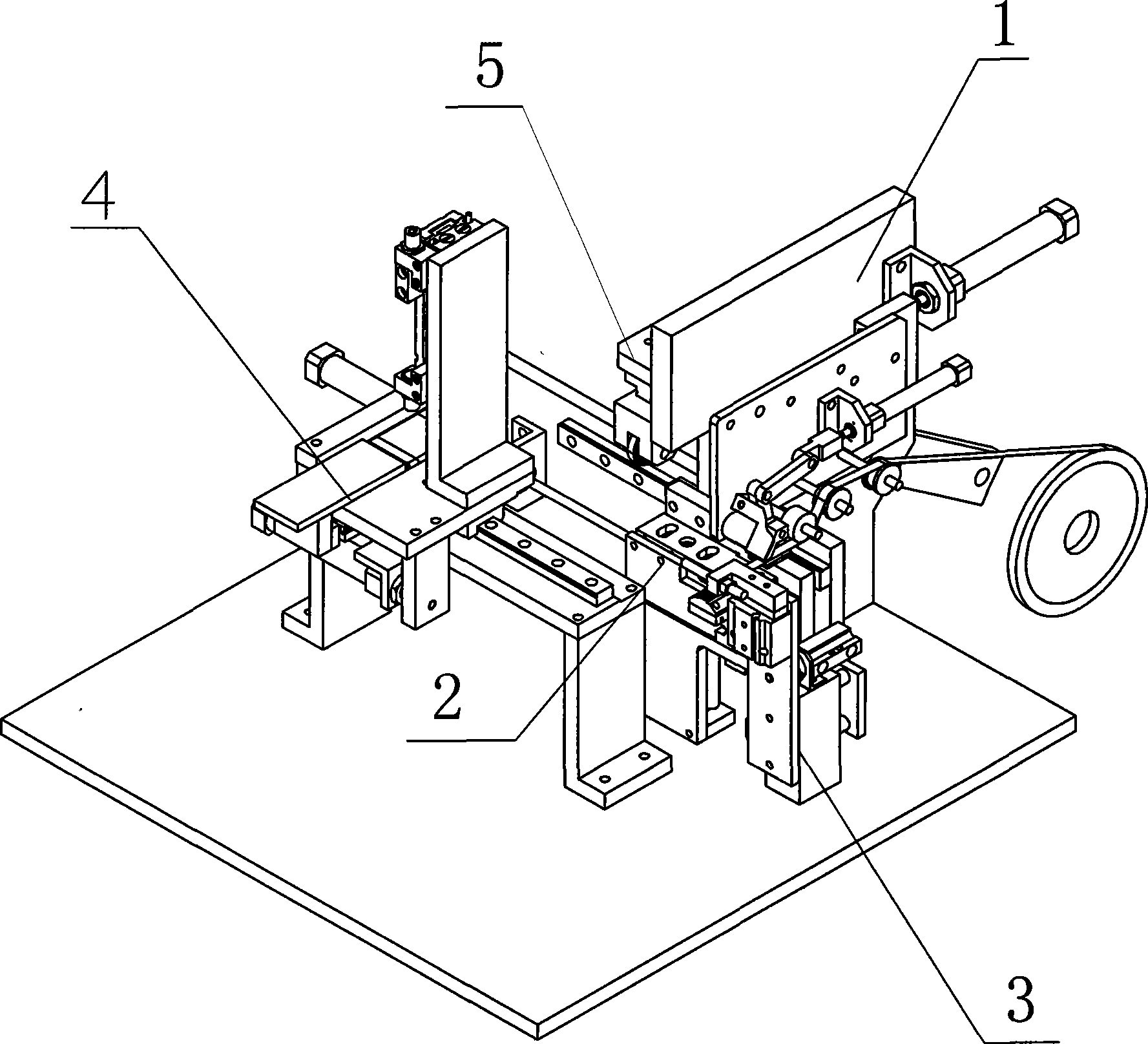

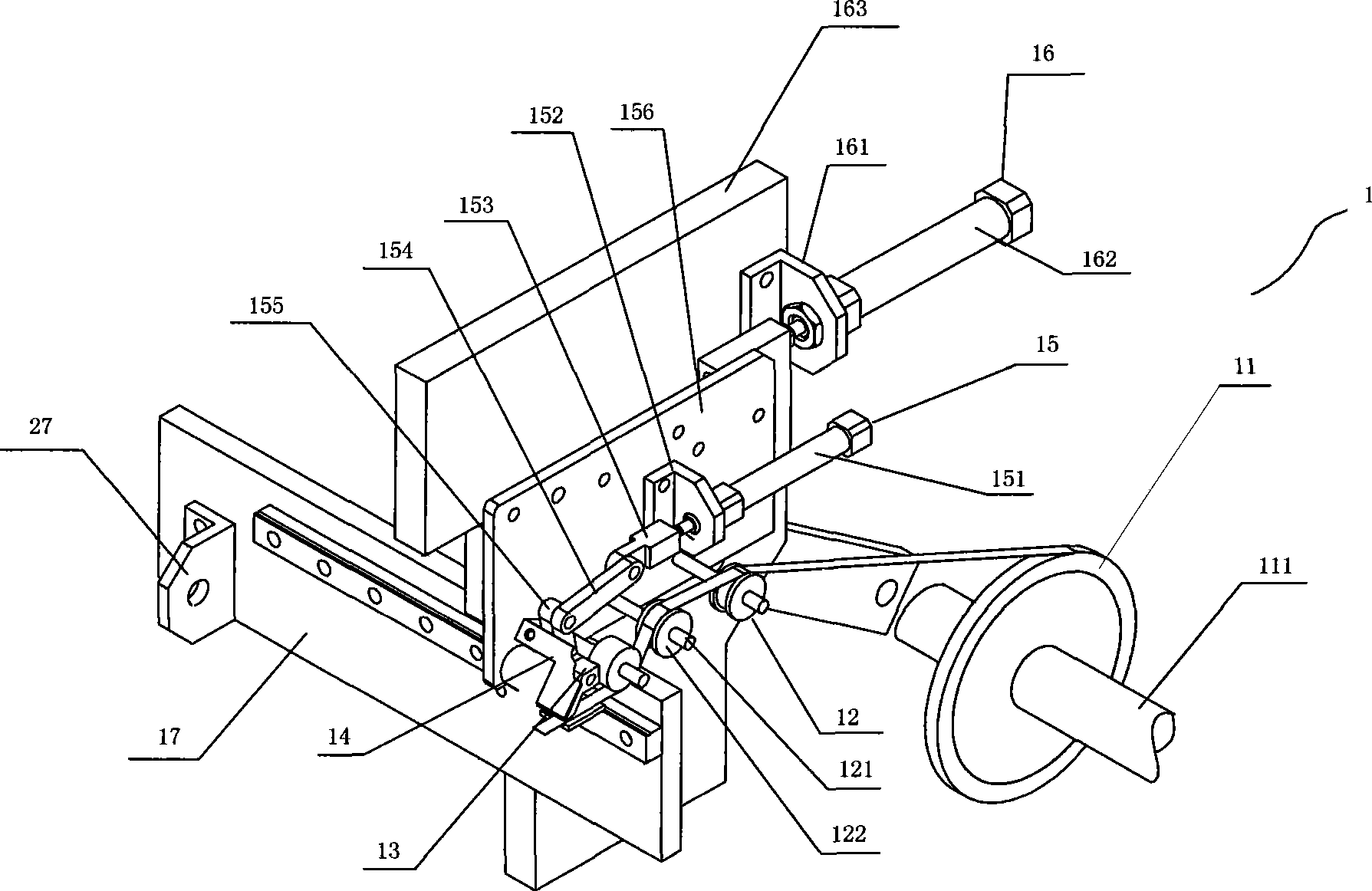

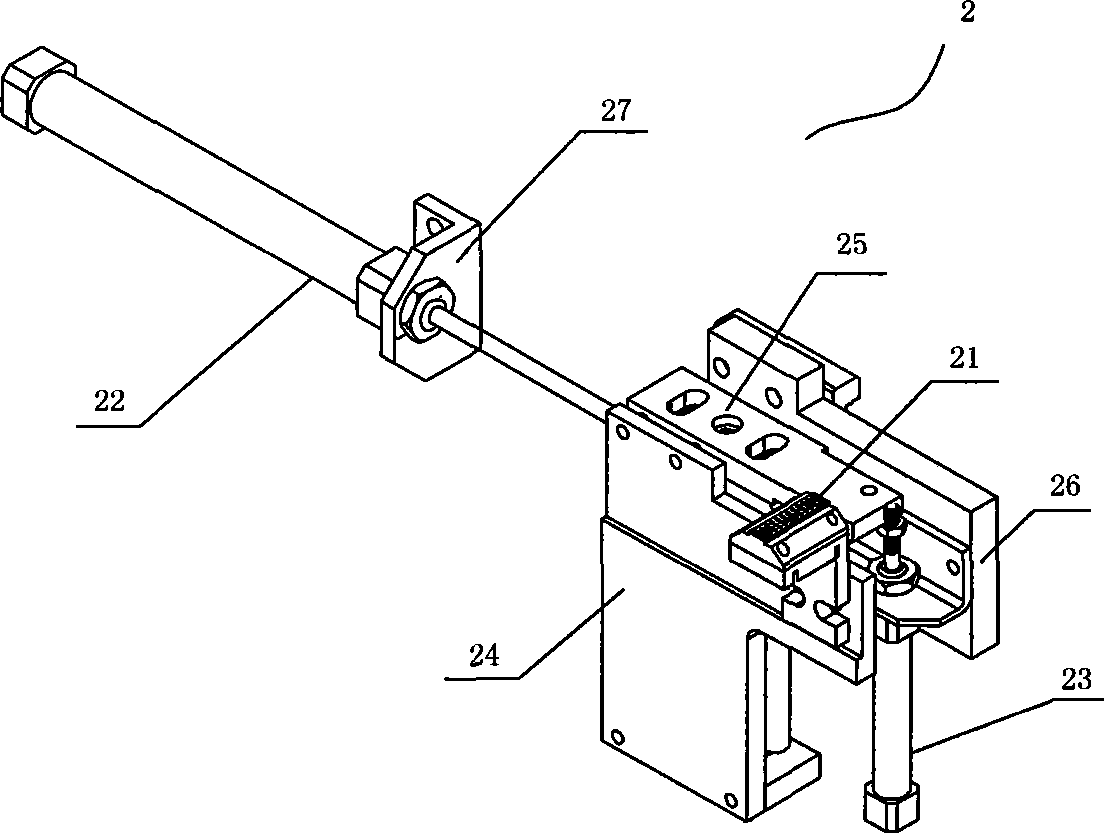

[0057] Such as figure 1 As shown, the present invention includes a glued paper part 1, a glued paper moving part 2, a glued paper part 3, a workpiece placement moving part 4 and a glued paper part 5, and the glued paper part 1 will be wound into a disc The adhesive paper core sends the adhesive paper to the adhesive paper cutting station through the transmission mechanism. After unwinding to the set length, the adhesive paper is compressed by the adhesive paper pressing part 3 located on the station, and cut off with a cutter. , and then send the tightly compressed adhesive tape to the workpiece placement station through the adhesive tape moving part 2, and at the same time, the workpiece placement moving part 4 pushes the workpiece on the workpiece placement table to the sticker station, and then uses the workpiece pressing device to compress it , and then the adhesive tape sent by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com