Combined machining method for chemistry cluster magneto-rheological of monocrystal silicon carbide wafer

A single crystal silicon carbide and composite processing technology, applied in the field of chemical cluster magnetorheological composite processing and crystal material processing, can solve the problems of low processing efficiency, long processing time, and reduced pressure of processing surface polishing, achieving ingenious conception, Ease of use and improved polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

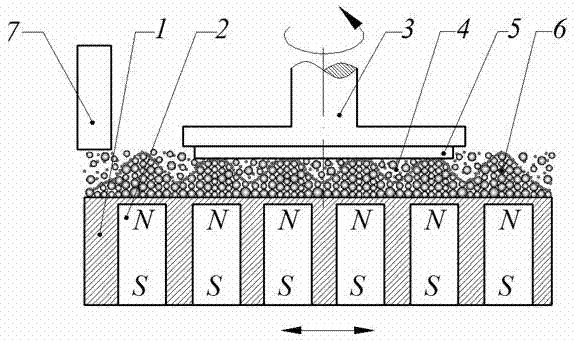

[0029] Step 1: Embedding clustered cylindrical magnets 2 with an end surface magnetic field strength of 2000GS on the antimagnetic polishing disc 1 to form a clustered magnetorheological polishing disc;

[0030] Step 2: The carbon surface of the single crystal silicon carbide wafer 5 is bonded on the antimagnetic tool head 3 through an adhesive, and the antimagnetic tool head 3 is installed on the motor spindle; in this embodiment, the antimagnetic tool head 3 can be Stainless steel tool head.

[0031] Step 3: Add 15% SiO in deionized water 2 CPI-SiO with an average particle size of 5um formed by coating carbonyl iron powder (CIP) on the surface of colloidal particle surface directional deposition method 2 Composite particles, diamond abrasive with an average particle size of 3um at a concentration of 10%, glycerin at a concentration of 10%, hydrogen peroxide at a concentration of 15%, and the pH value is adjusted to 10-12 by adding sodium hydroxide to form a chemical magneto...

Embodiment 2

[0038] Step 1: Embedding clustered cylindrical magnets 2 with an end surface magnetic field strength of 2000GS on the antimagnetic polishing disc 1 to form a clustered magnetorheological polishing disc;

[0039] Step 2: bonding the silicon surface of the single crystal silicon carbide wafer 5 to the antimagnetic tool head 3 through an adhesive, and the antimagnetic tool head 3 is installed on the motor spindle;

[0040] Step 3: Add 15% modified CIP composite particles with an average particle size of 5um obtained by modifying the surface of carbonyl iron powder (CIP) with tetraethyl orthosilicate (TEOS) at a concentration of 15% in deionized water. The diamond abrasive with an average particle size of 3um, the concentration of 10% glycerin, and the concentration of 15% hydrogen peroxide, and by adding dilute hydrofluoric acid to adjust the pH value to 2-4, form a chemical magnetorheological fluid 4.

[0041] Step 4: Pour the chemical magnetorheological fluid 4 into the constan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com