Drum-type turner

A flipping machine and drum type technology, which is applied in the direction of throwing machine, sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of low hydraulic transmission efficiency, many mechanical failures, and large material extrusion. Achieve the effect of high mechanical transmission efficiency, low operating cost and low power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

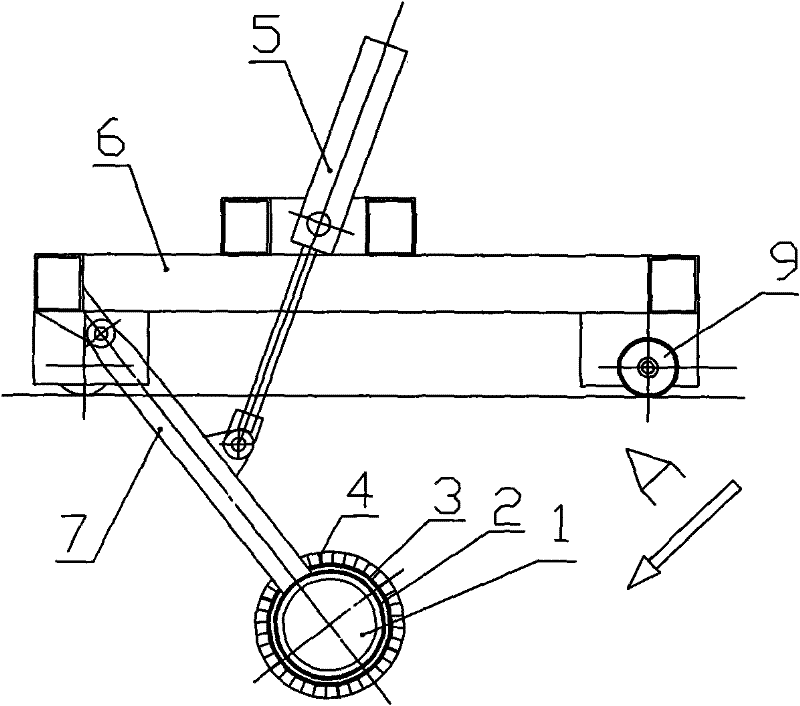

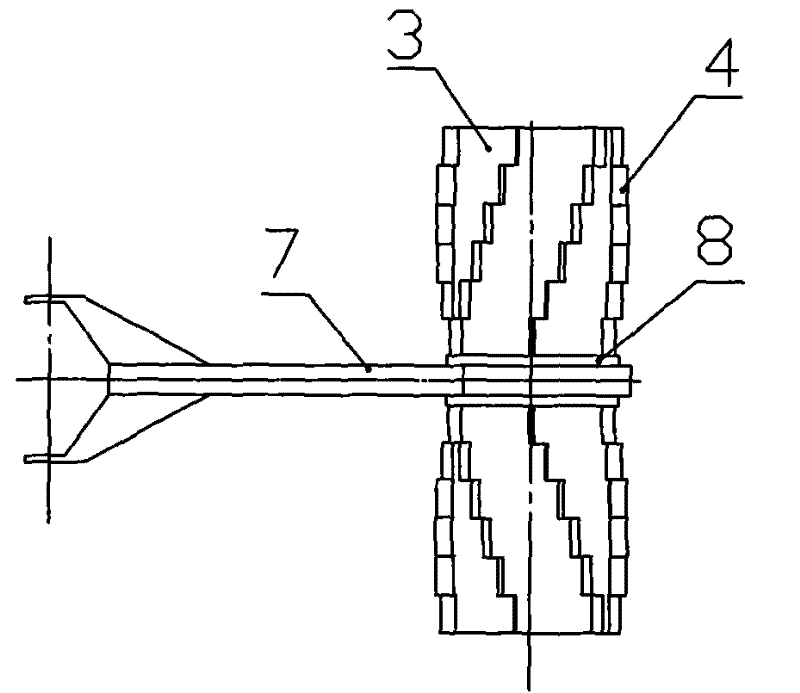

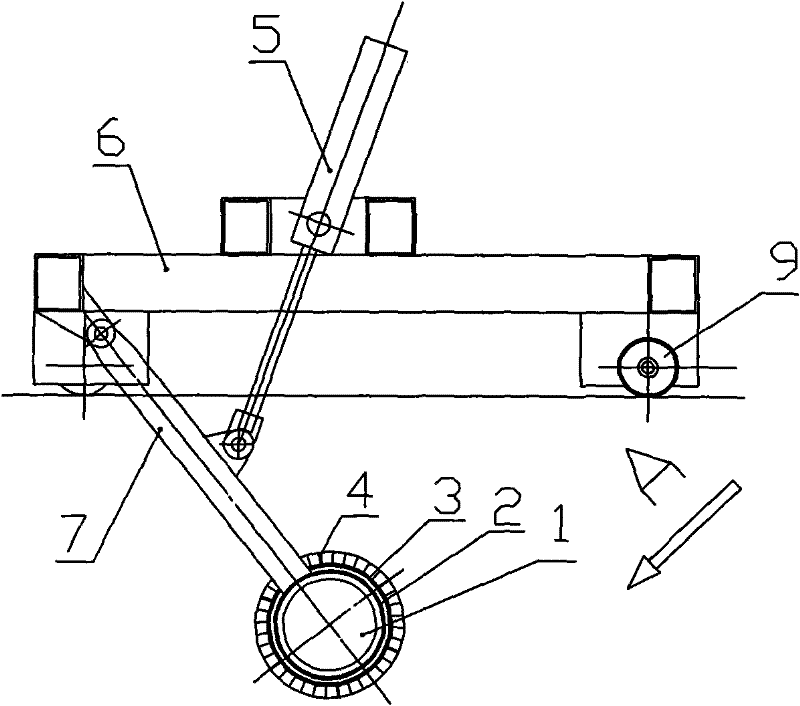

[0009] Such as figure 1 As shown, the throwing machine is made up of a geared motor (1), a vehicle body (6), a running gear, a slewing arm (7), a drum (3), a lift (5) and the like. There is a pin hole at one end of the slewing arm, which is fixed on the body with a pin shaft; the middle part of the slewing arm has an ear iron connected with the elevator, and the height of the roller can be adjusted through the lifting of the elevator; the other end of the slewing arm is welded with a sleeve; The sleeve is fixed with a snap ring; a roller is installed on the output shaft of the geared motor, and a stepped web is welded on the outer periphery of the roller; a brush-type sealing mechanism is installed between the roller and the sleeve.

[0010] The body of the turner can be installed with a silo and a discharge machine, so that the turner has the function of spreading materials; it can also be installed with a lifting workbench, so that the turner has a detection function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com