Electric turbocharger

A turbocharger and supercharger technology, applied in clutches, machines/engines, magnetic drive clutches, etc., can solve the problems of inability to further increase the speed, low utilization rate of exhaust gas energy, and excessive rotor vibration, so as to improve the turbocharger. Rotordynamic performance, reducing energy consumption, solving the effect of turbo lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to explain the technical solutions of the present invention more clearly, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

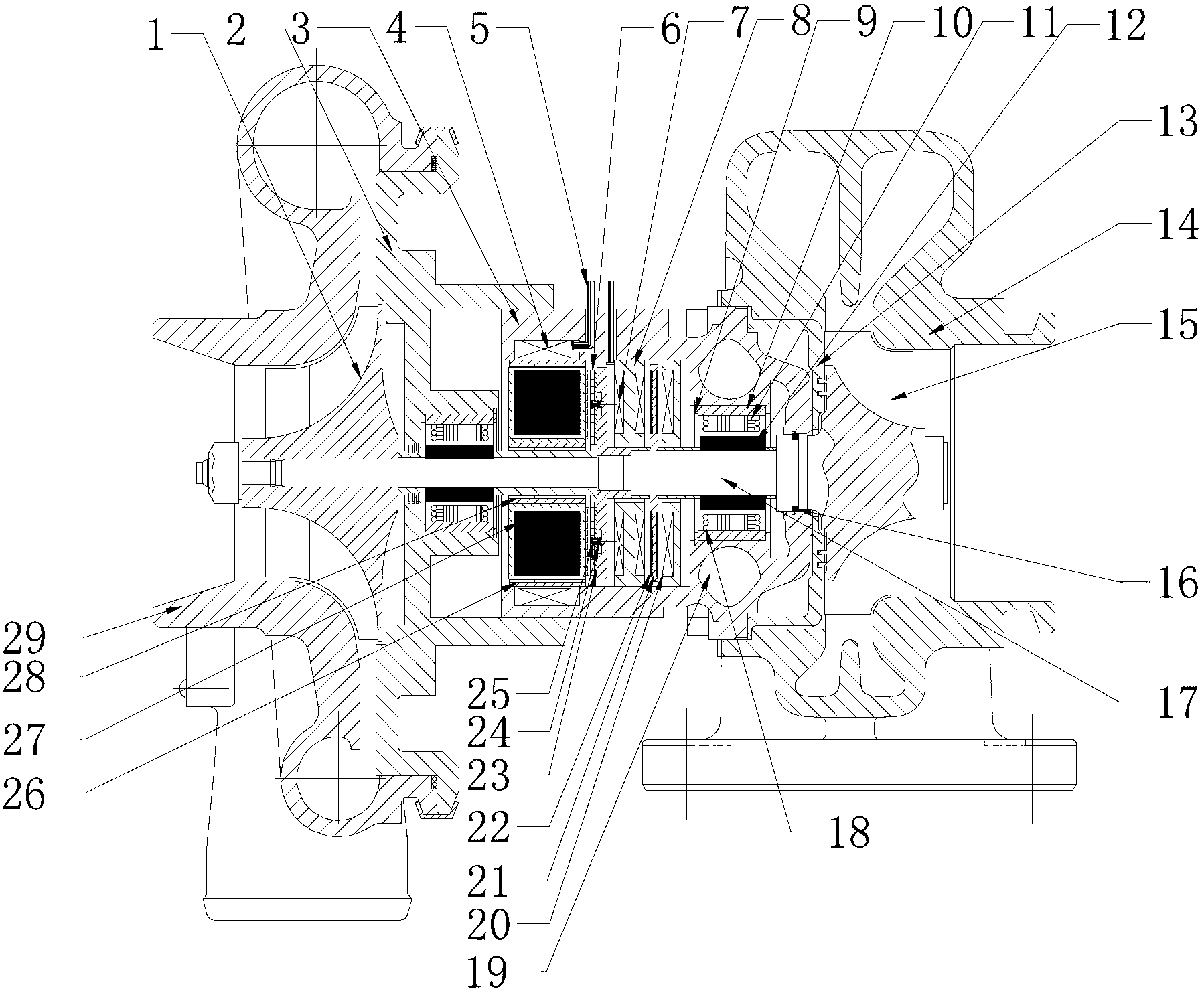

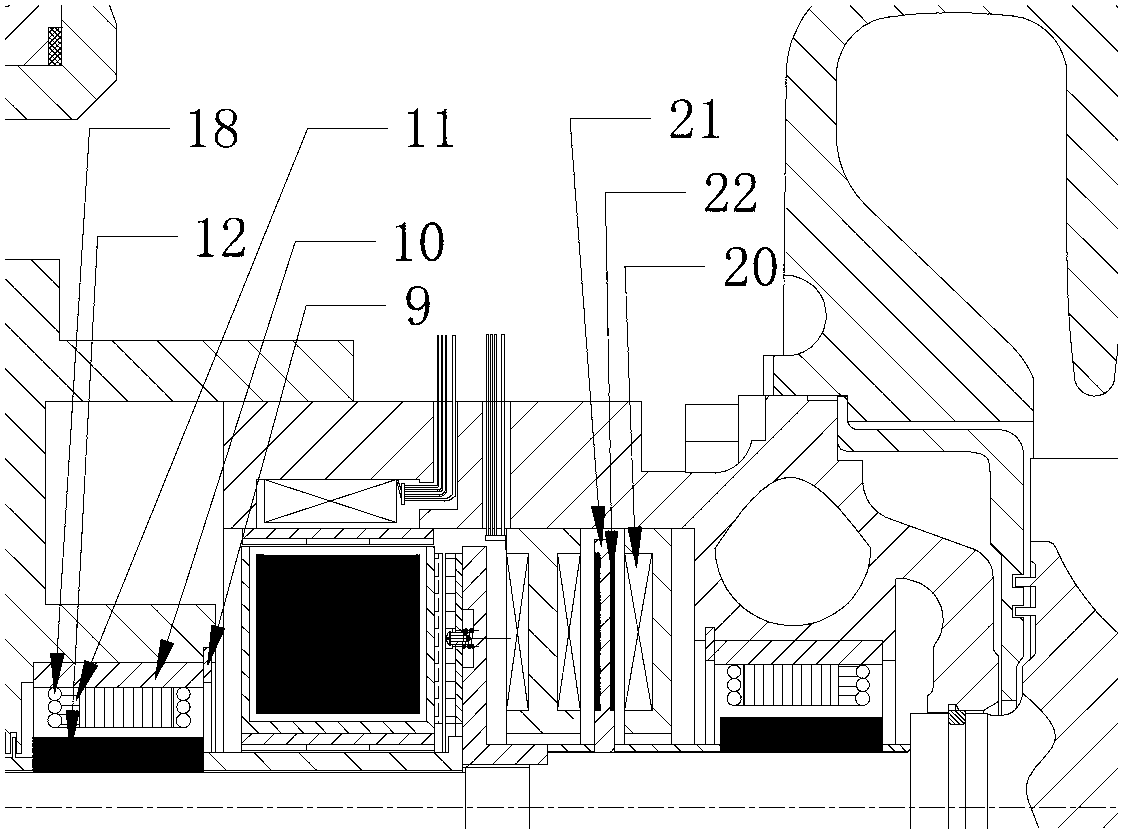

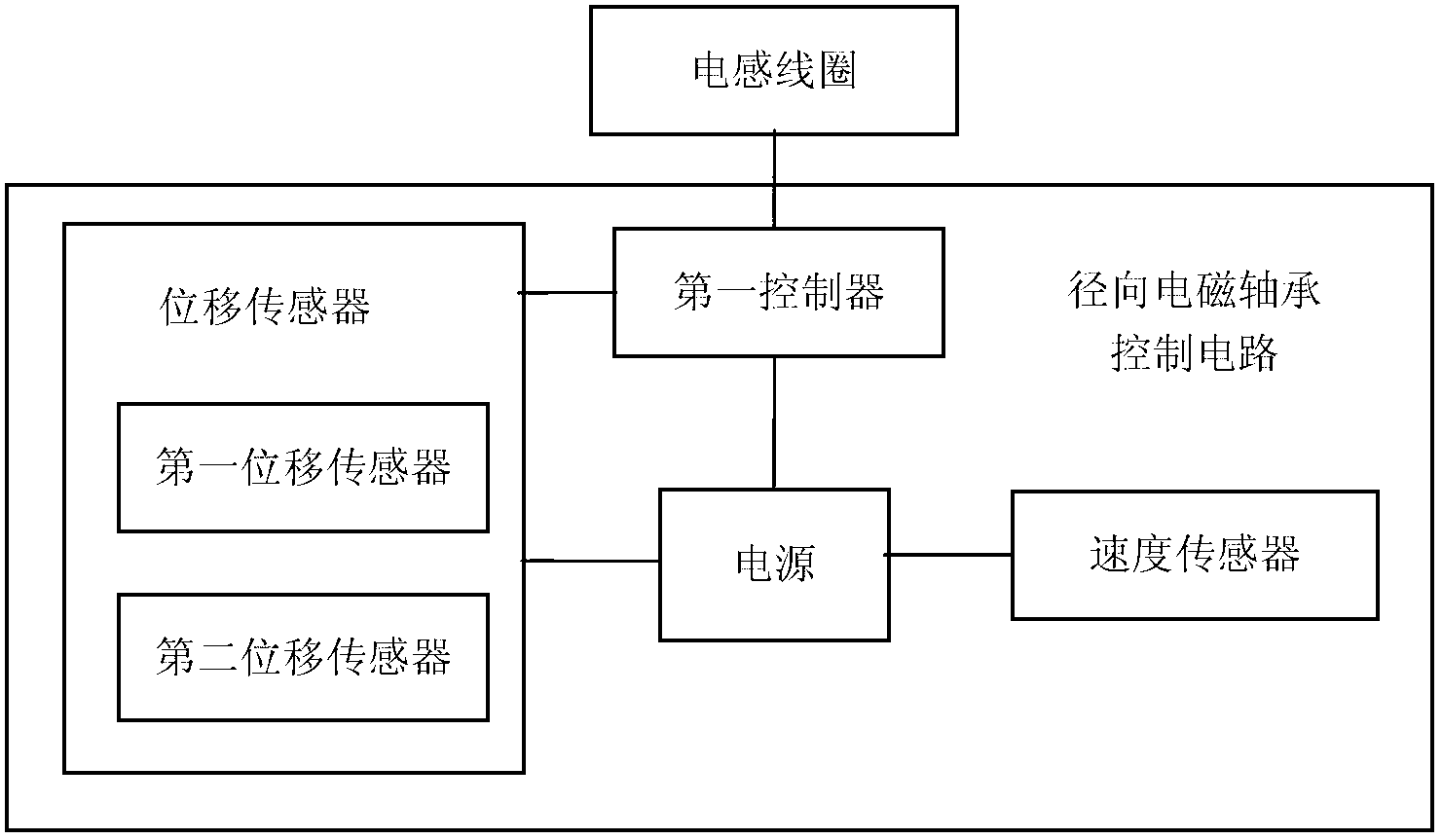

[0030] Such as figure 1 , figure 2 As shown, the electric turbocharger of the present invention includes a compressor, an intermediate body 3, a rotor shaft 17, a turbine, a bearing, a radial electromagnetic bearing, a radial electromagnetic bearing control circuit, an axial electromagnetic bearing 8, an axial electromagnetic bearing Bearing 8 control circuit, motor generator, clutch device and clutch control system. The compressor includes a compressor wheel 1, a compressor housing 29, and a compressor back plate 2. The turbine includes a turbine housing 14 and a turbine wheel 15. The rotor shaft 17 is a rotor shaft 17 with a turbine wheel 15 at one end, The compressor impeller 1 is assembled on the compressor end of the rotor shaft 17. The turbine wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com