Joined raw-edge V-belt and manufacturing method thereof

A technology of trimming and tape, applied in the direction of V-shaped belts, belts, and other household appliances, etc., can solve the problems of uneven transmission power, easy jumping, turning over, V-belt length error, etc., to achieve uniform transmission power, stable operation, The effect of force balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

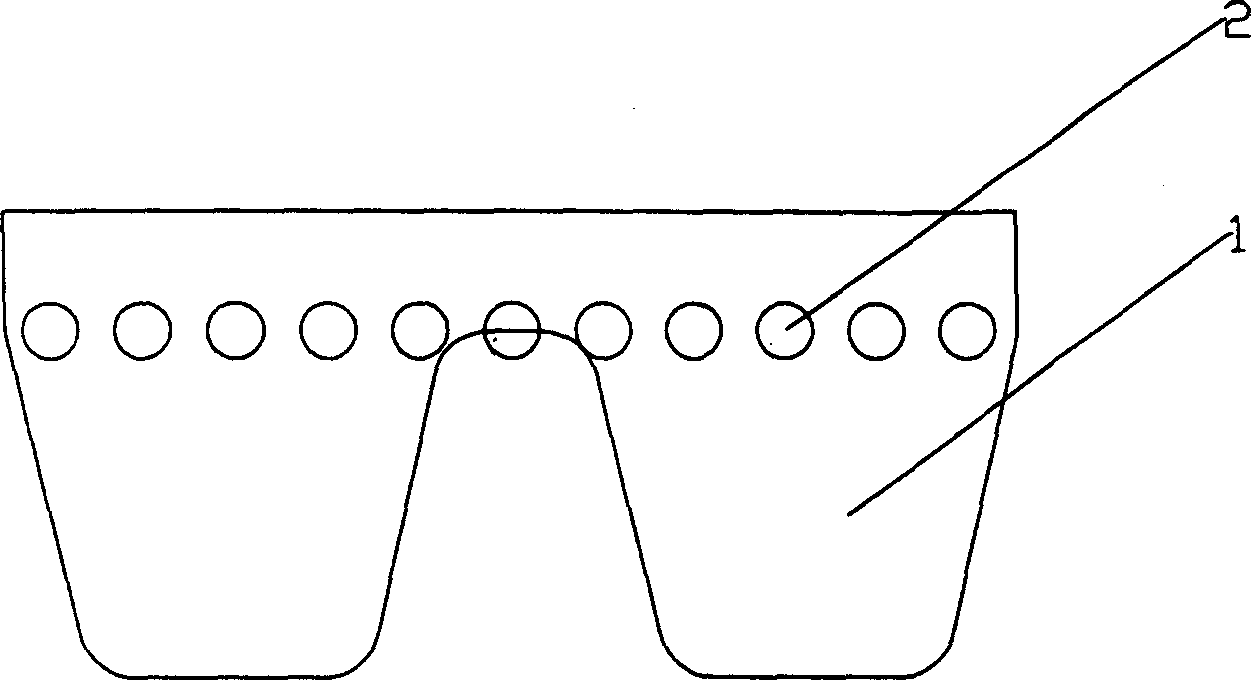

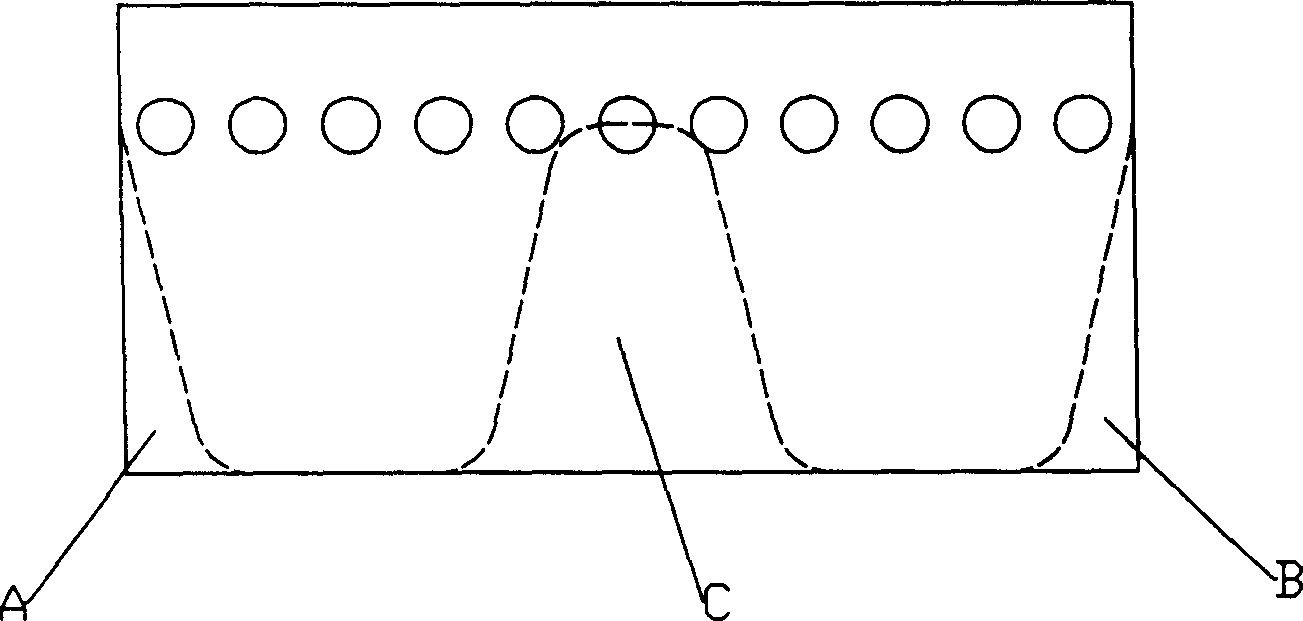

[0024] like figure 1 As shown, a group trimmed V-belt is composed of more than two V-belts connected side by side to form an integrated structure, and a skeleton is arranged inside the V-belt. The lower part of the V-belt is a tooth-shaped part, and the upper part is a flat bottom. The adjacent V-belts are connected to form an integrated structure through the flat bottom. The skeleton is set at the transition between the tooth-shaped part and the flat bottom. The V-belt is a neoprene V-belt; the skeleton is a polyester hard cord.

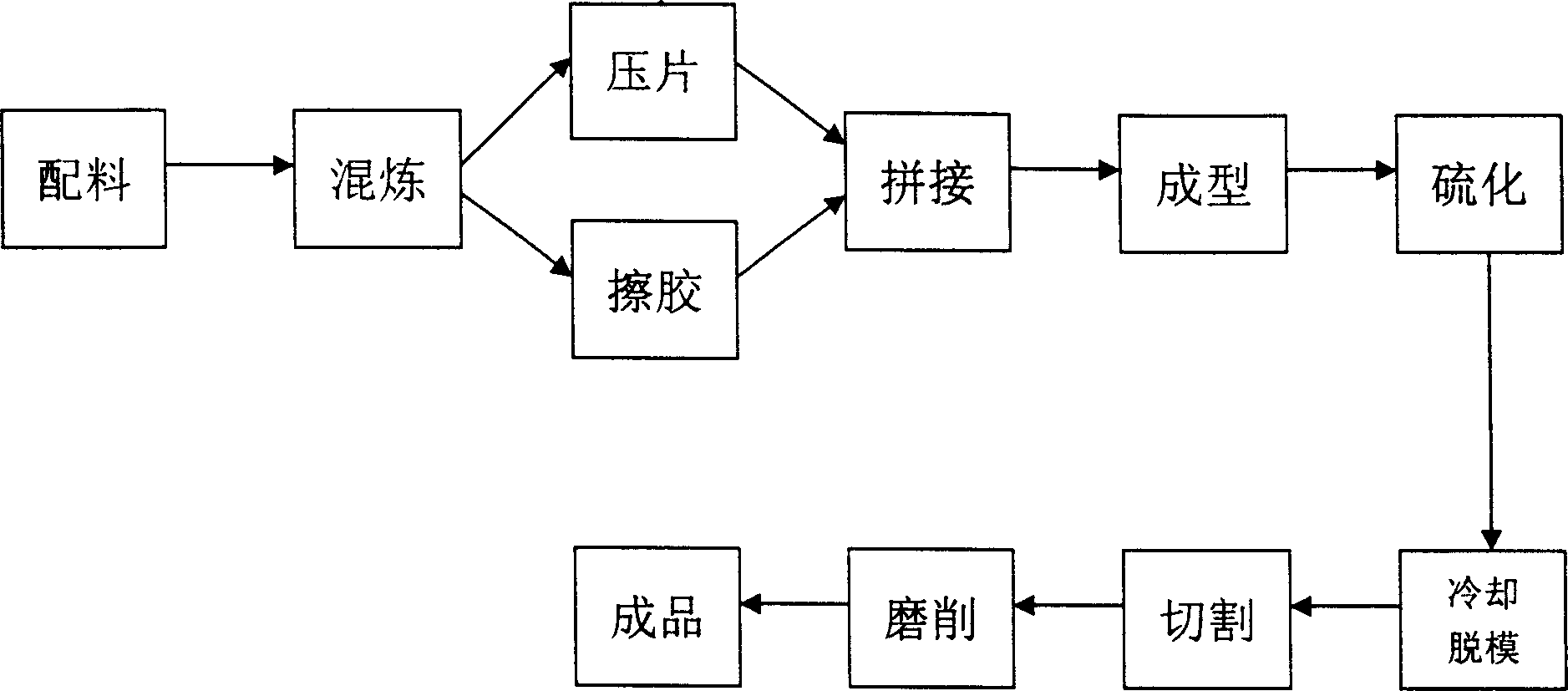

[0025] Combined trimming V-belt adopts the following manufacturing method, such as image 3 Process shown:

[0026] a. Ingredients: weigh the raw materials according to the formula;

[0027] b. Mixing: Mix the weighed raw materials in the internal mixer according to the process to make a mixed rubber;

[0028] c. Tablet pressing: Press the mixed rubber into various thicknesses according to the requirements on the open mill, control the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com