Glass fiber reinforced unplasticised polyvinyl chloride material and preparation thereof

A kind of hard polyvinyl chloride and glass fiber technology, applied in the field of glass fiber reinforced hard polyvinyl chloride material and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 Preparation of glass fiber reinforced hard polyvinyl chloride material

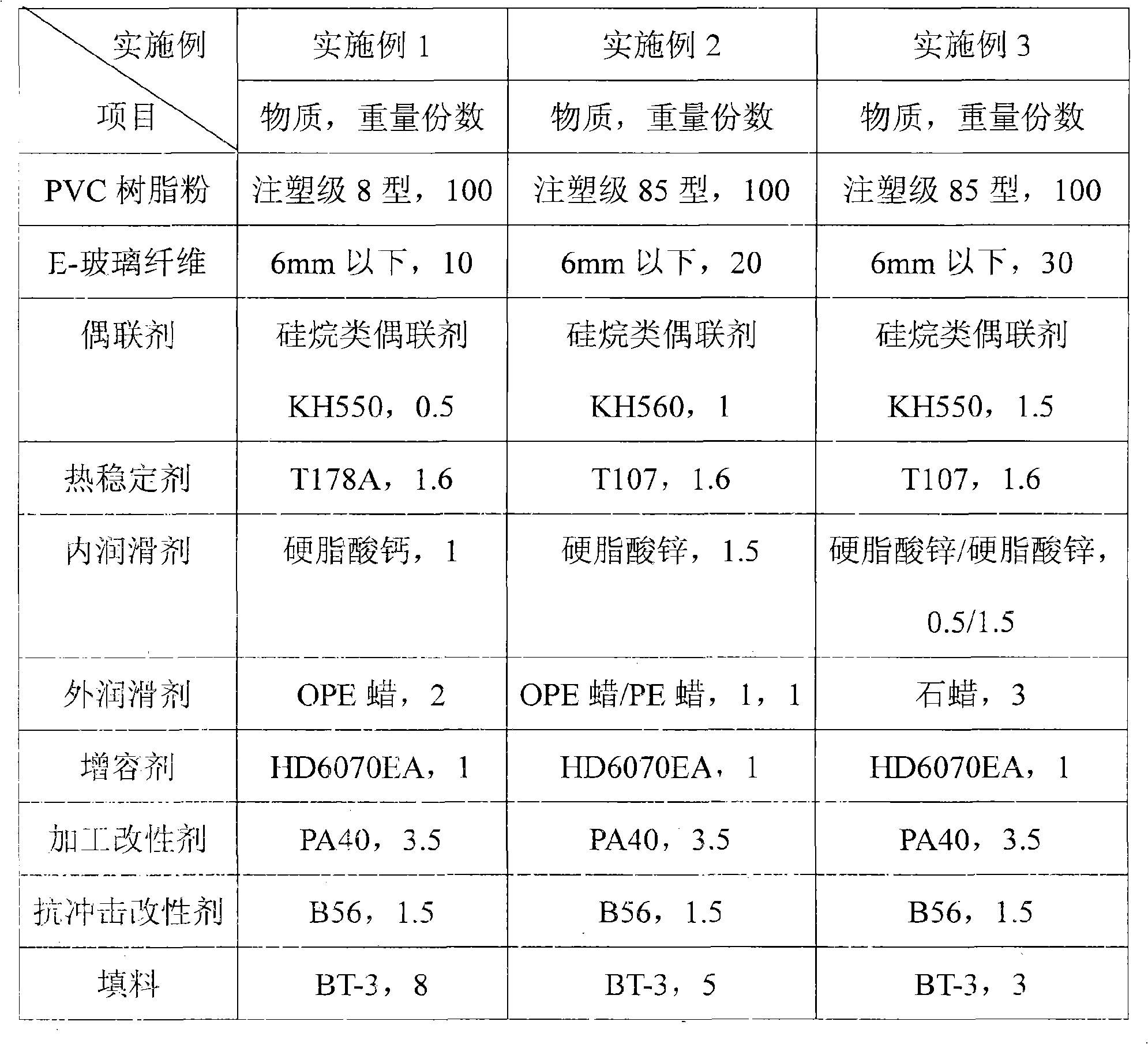

[0035] The glass fiber reinforced hard polyvinyl chloride material of this embodiment, its components and required parts by weight are shown in Table 1.

[0036] The preparation method of the glass fiber reinforced hard polyvinyl chloride material of the present embodiment comprises the steps:

[0037] (1) Glass fiber pre-coupling treatment: first spray the glass fiber with a coupling agent, and easily stir the glass fiber;

[0038](2) Prepare mixed ingredients: mix PVC resin powder with heat stabilizer, lubricant, compatibilizer, processing modifier, impact modifier, filler, etc. at high speed to 90°C, and obtain PVC mixed ingredients after mixing evenly ;

[0039] (3) Stirring at a low speed with the PVC compounding material that step (2) obtains and the glass fiber that step (1) is processed, mix uniformly;

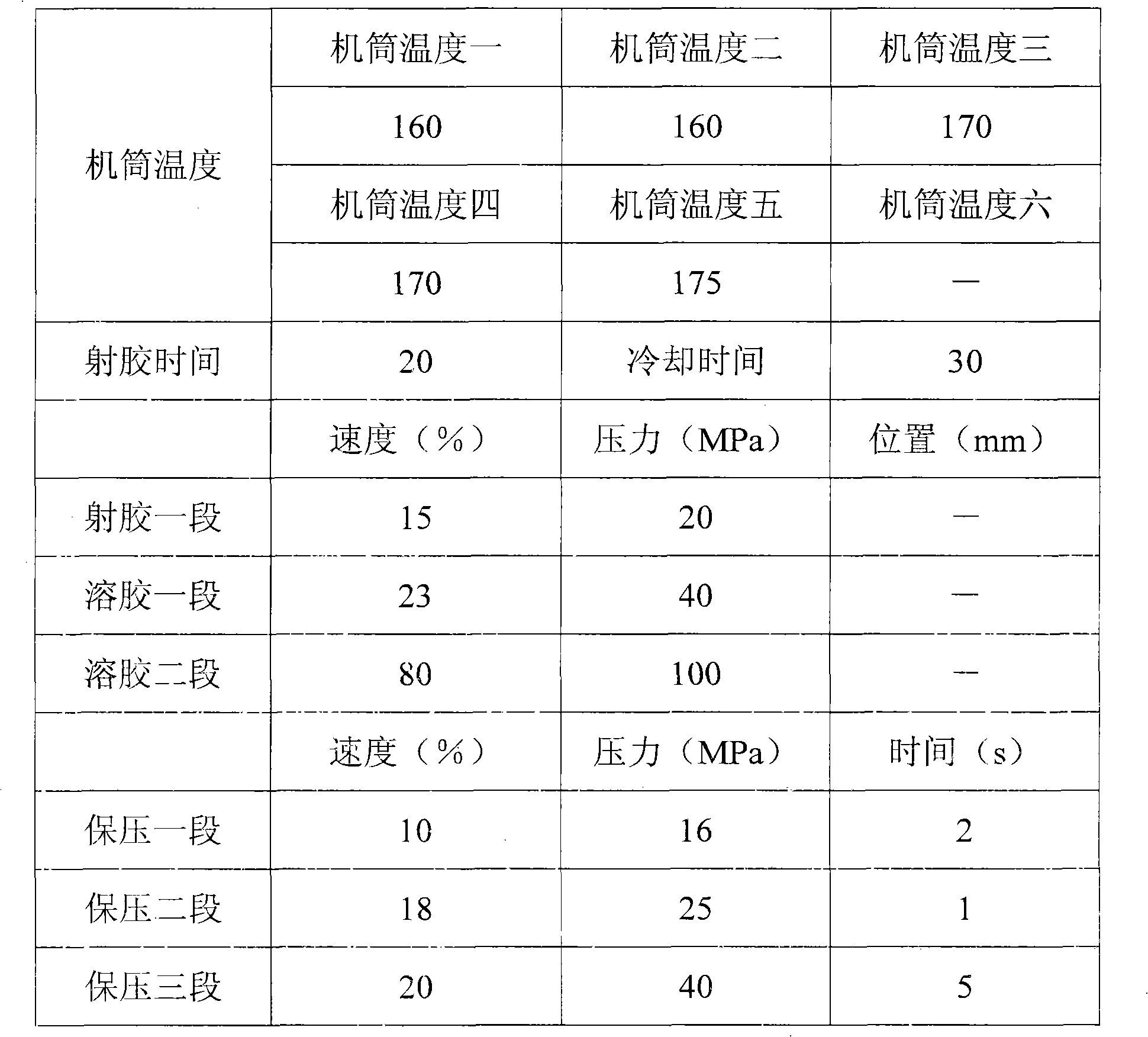

[0040] (4) Open granulation: put all the mixed materials into the combi...

Embodiment 2

[0047] Embodiment 2 Preparation of glass fiber reinforced hard polyvinyl chloride material

[0048] The glass fiber reinforced hard polyvinyl chloride material of this embodiment, its components and required parts by weight are shown in Table 1.

[0049] The preparation method of the glass fiber reinforced hard polyvinyl chloride material of the present embodiment comprises the steps:

[0050] (1) Glass fiber pre-coupling treatment: first spray the glass fiber with a coupling agent, and easily stir the glass fiber;

[0051] (2) Prepare mixed ingredients: mix PVC resin powder with heat stabilizer, lubricant, compatibilizer, processing modifier, impact modifier, filler, etc. at high speed to 110°C, and obtain PVC mixed ingredients after mixing evenly ;

[0052] (3) Stirring at a low speed with the PVC compounding material that step (2) obtains and the glass fiber that step (1) is processed, mix uniformly;

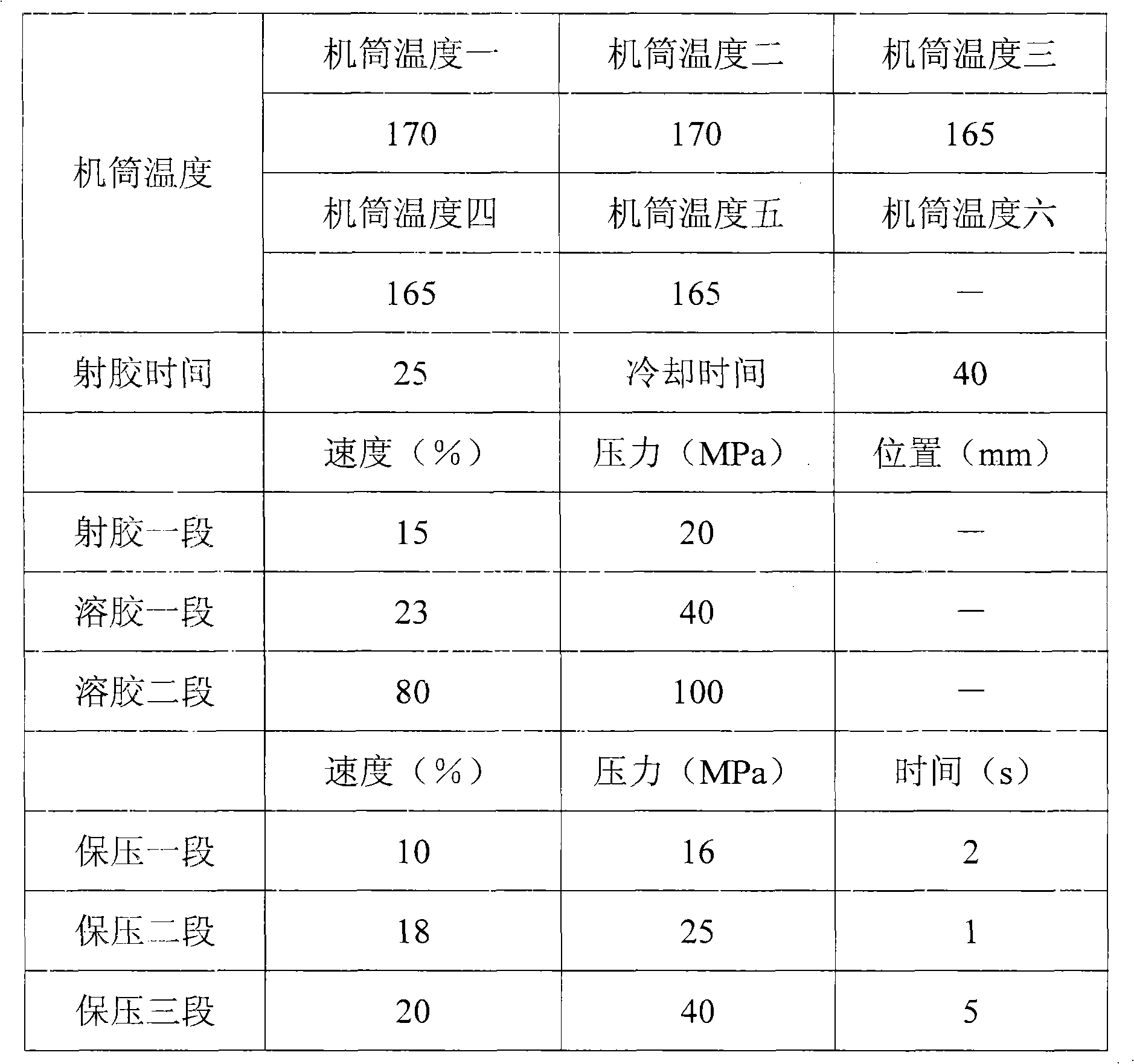

[0053] (4) Open granulation: put all the mixed materials into the com...

Embodiment 3

[0058] Example 3 Preparation of Glass Fiber Reinforced Rigid Polyvinyl Chloride Material

[0059] The glass fiber reinforced hard polyvinyl chloride material of this embodiment, its components and required parts by weight are shown in Table 1.

[0060] The preparation method of the glass fiber reinforced hard polyvinyl chloride material of the present embodiment comprises the steps:

[0061] (1) Glass fiber pre-coupling treatment: first spray the glass fiber with a coupling agent, and easily stir the glass fiber;

[0062] (2) Prepare mixed ingredients: mix PVC resin powder with heat stabilizer, lubricant, compatibilizer, processing modifier, impact modifier, filler, etc. at high speed to 100°C, and obtain PVC mixed ingredients after mixing evenly ;

[0063] (3) Stirring at a low speed with the PVC compounding material that step (2) obtains and the glass fiber that step (1) is processed, mix uniformly;

[0064] (4) Open granulation: put all the mixed materials into the combi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com