Vane regulation control device

A technology of regulating control and guide vane, which is applied in pump control, components of pumping devices for elastic fluids, non-variable pumps, etc., can solve deviation from design conditions, exhaust gas diffusion section and unfavorable flow in combustion chamber Influence and other issues, to achieve uniform flow field, increase efficiency, and improve the effect of outlet flow field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

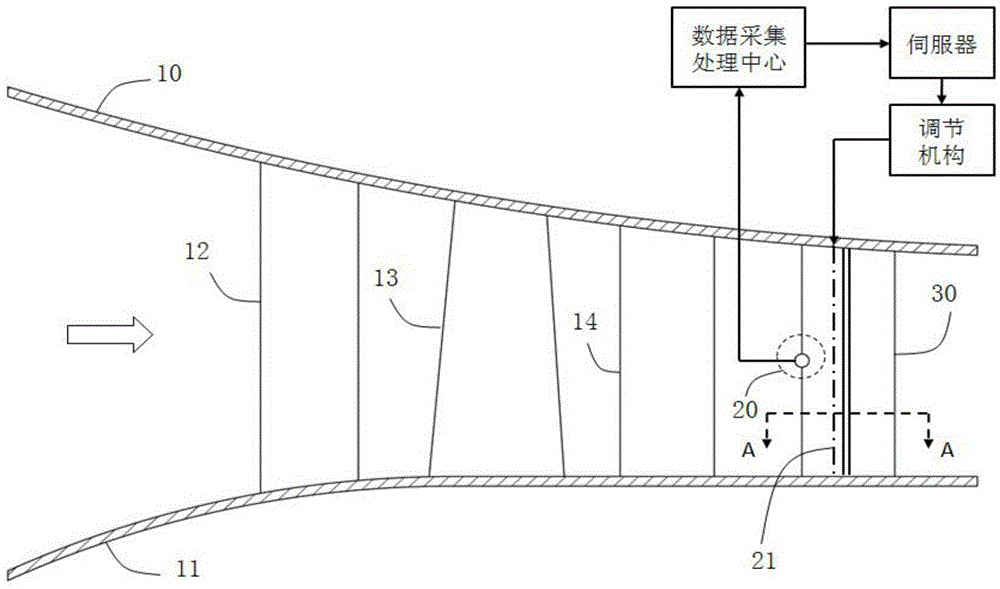

[0041] see Figure 1 to Figure 3 , the present invention discloses a guide vane adjustment control device (which can be used as a part of the compressor), including a cylinder 10, a hub 11, a moving vane 13, a stationary vane 14, an inlet guide vane 12, a variable geometry outlet guide vane 30, a guide vane Adjust the control system.

[0042] figure 1 A schematic diagram of the meridional flow of a compressor is shown, and the flow of the compressor is composed of moving blades 13, stationary blades 14, cylinders 10, and hubs 11. The gas flows through the inlet guide vane 12, pre-swirls to the rotor blade 13 at the outlet of the inlet guide vane 12, and then is compressed into a high-pressure gas in the rotor blade 13 and stationary vane 14, and the temperature also rises accordingly. Compressed air flows in the channel between the hub 11 and the cylinder 10; the rotor blade 13 is installed on the hub 11, the stationary vane 14 is installed on the cylinder 10, and the air fl...

Embodiment 2

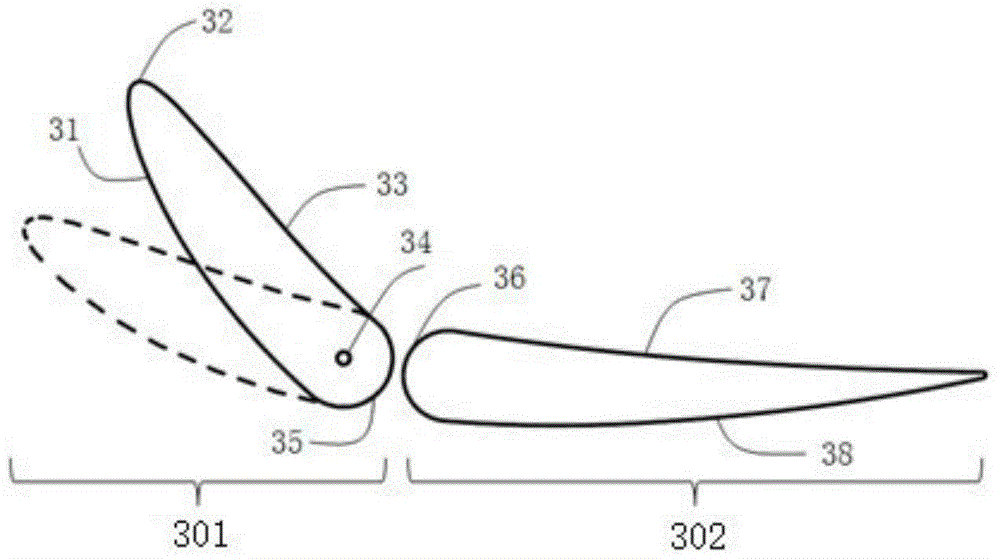

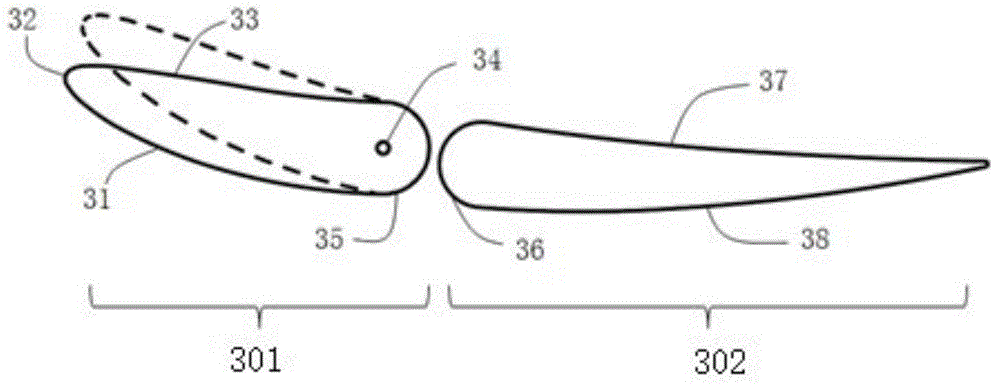

[0054] In order to prevent the compressor from stalling or clogging when it operates under variable working conditions, and considering the requirements of the combustion chamber and the exhaust diffuser section on the airflow angle at the outlet of the guide vane, the outlet is designed to be adjusted in sections, the front section is adjustable, and the rear section is fixed. It can not only ensure that the inlet angle of attack will not be too large under non-design working conditions, but also avoid the adverse effect of the change of the outlet airflow angle on the flow of the exhaust diffusion section.

[0055] In this embodiment, the variable geometry outlet guide vane includes an adjustable inlet section and a fixed outlet section, and there is a gap between the trailing edge of the adjustable inlet section and the front edge of the fixed outlet section; the gap should not be too large or too small. The gap is composed of two sections of smooth curves, through which the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com