Switchable foaming solution for foam drilling and well cleanup on oil and gas field

A technology of oil and gas drilling and foaming fluid, which is applied in the direction of flushing wellbore, wellbore/well parts, earthwork drilling and production, etc., to achieve the effects of easy biodegradation, cost reduction and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with embodiment:

[0014] The switch foaming liquid formula used in the following experiments is as follows (mass percentage): C8-C10 alkyl glycoside (APG) 0.5%, sodium oleate 0.2%, C6-C8 fatty alcohol polyoxyethylene ether sodium sulfate (AES) 0.1% , Ethylene glycol monobutyl ether 0.05%, EDTA 1.0%.

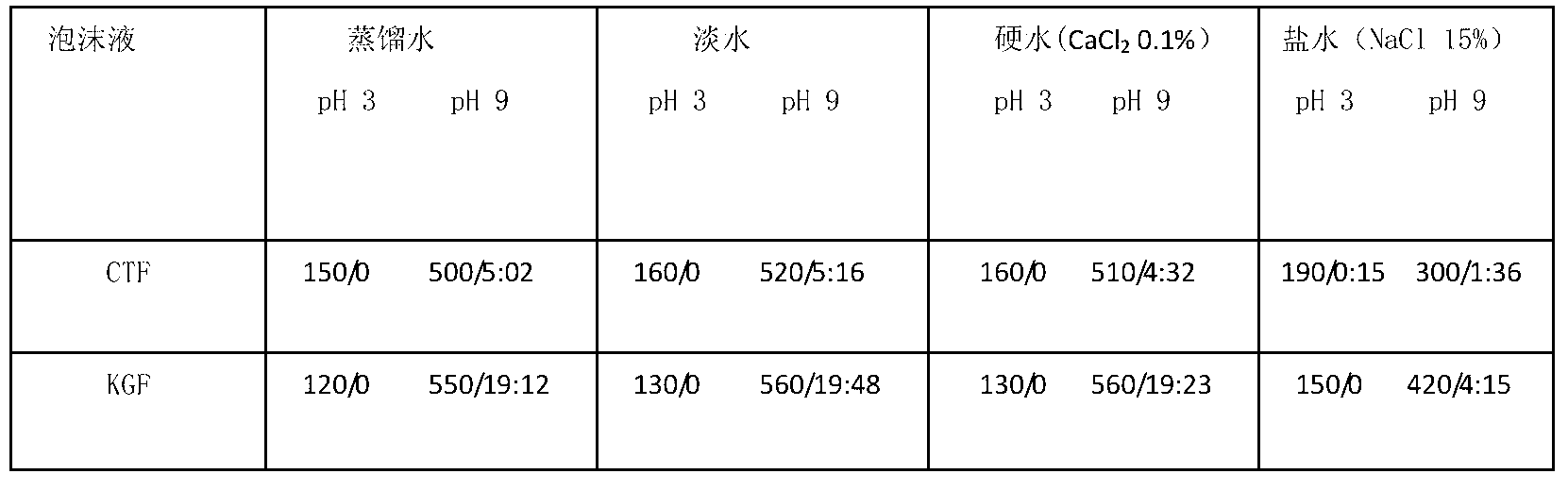

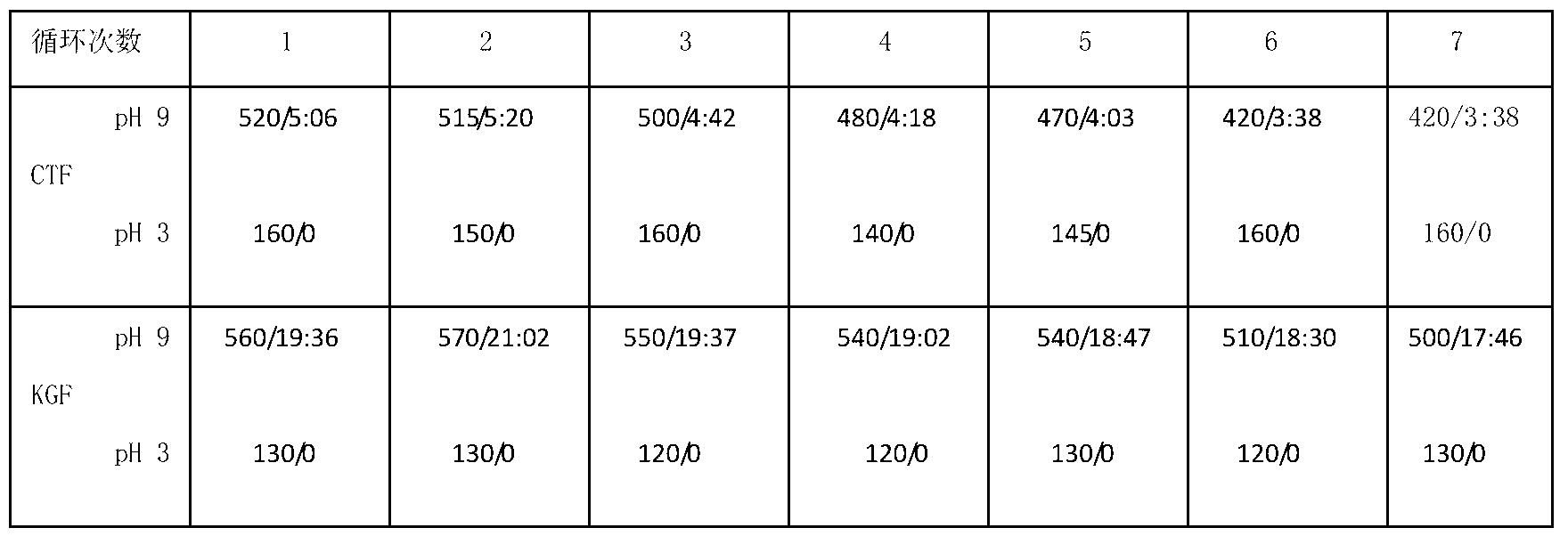

[0015] Foam performance testing. The Waring Blender stirring method was used to test the foam performance of the blowing agent under different conditions. The U.S. petroleum industry often adopts this method, and my country's petroleum industry also adopts this method. The instrument used is a Waring Blender stirrer. During the test, add 100ml of test liquid into a graduated mixing cup, stir at high speed (≧5000rpm) for 60s, turn off the switch, and immediately record the foam volume V (ml), which represents the foaming ability of the foaming agent, the greater the V , the stronger the foaming abilit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com