Method for preparing ultrafine boron carbide granulation powder by combining high-energy ball milling with spray drying technology

A technology of high-energy ball milling and boron carbide, which is applied in the field of high-energy ball milling combined with spray drying technology to prepare ultra-fine boron carbide granulated powder, can solve the problems of high cost and safety problems, and achieve the goal of increasing density, improving efficiency and maintaining uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Each raw material is batched according to the following mass percentages: boron carbide micropowder 20g (D 50 : 2.5~3.5μm), deionized water 20g, lubricant A 0.4g, glycerin 0.2g, dispersant 0.2g, binder A 1g, cyclodextrin 0.2g, water-soluble phenolic resin 2g, propylene glycol 0.02g;

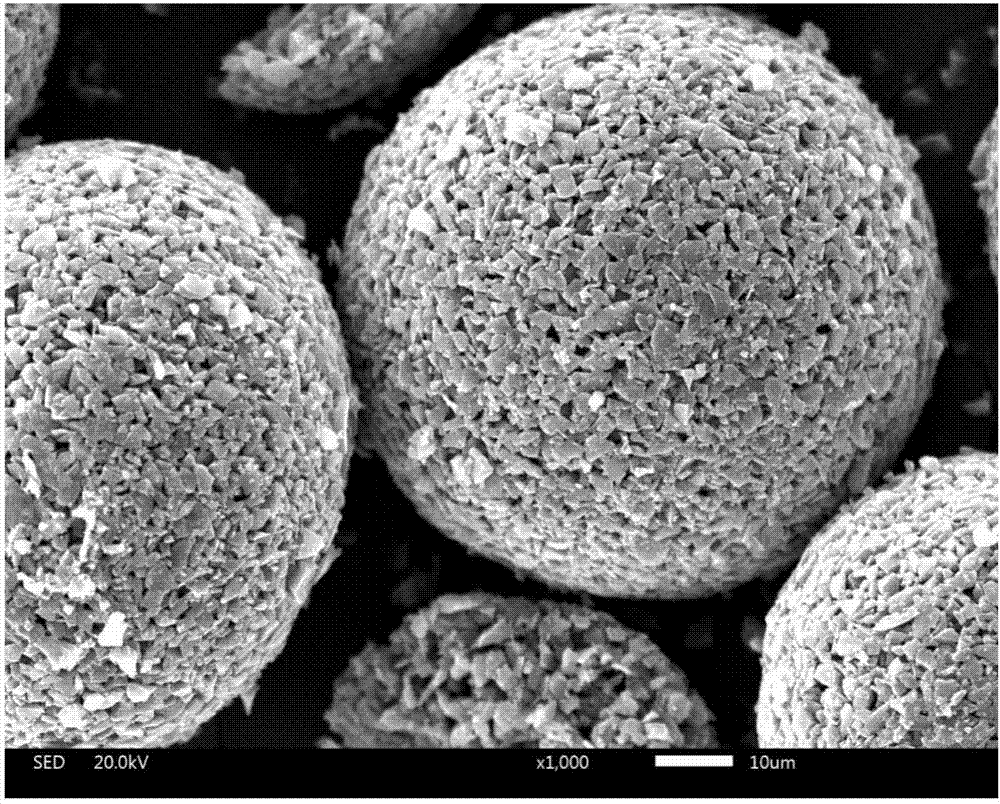

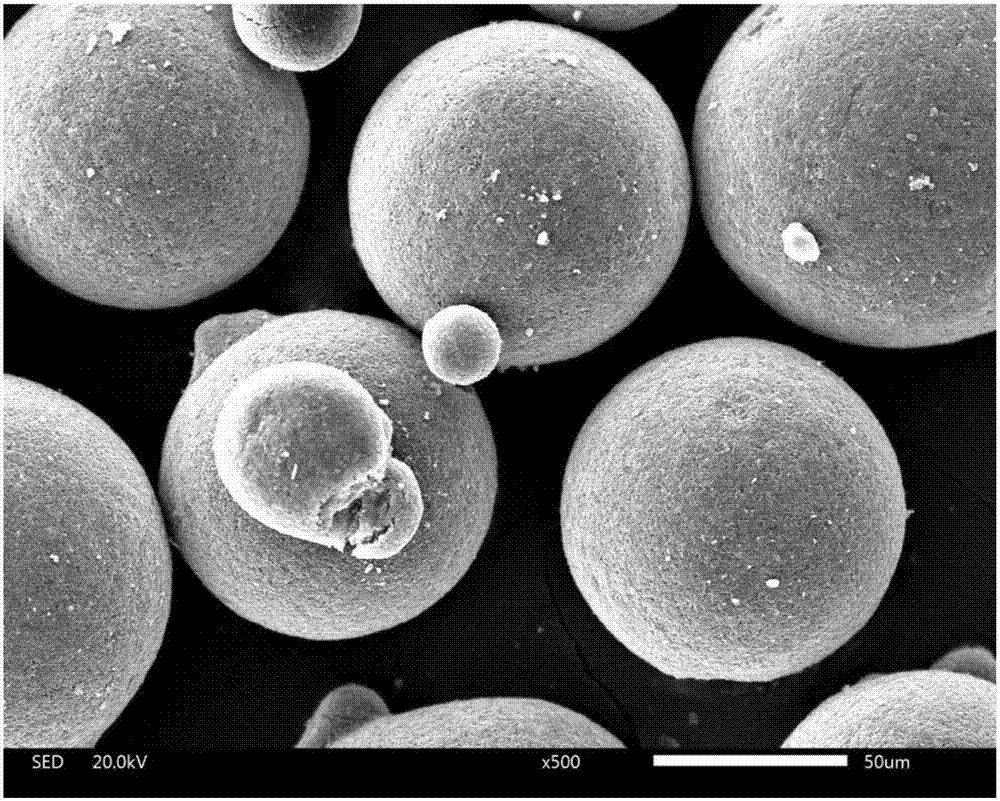

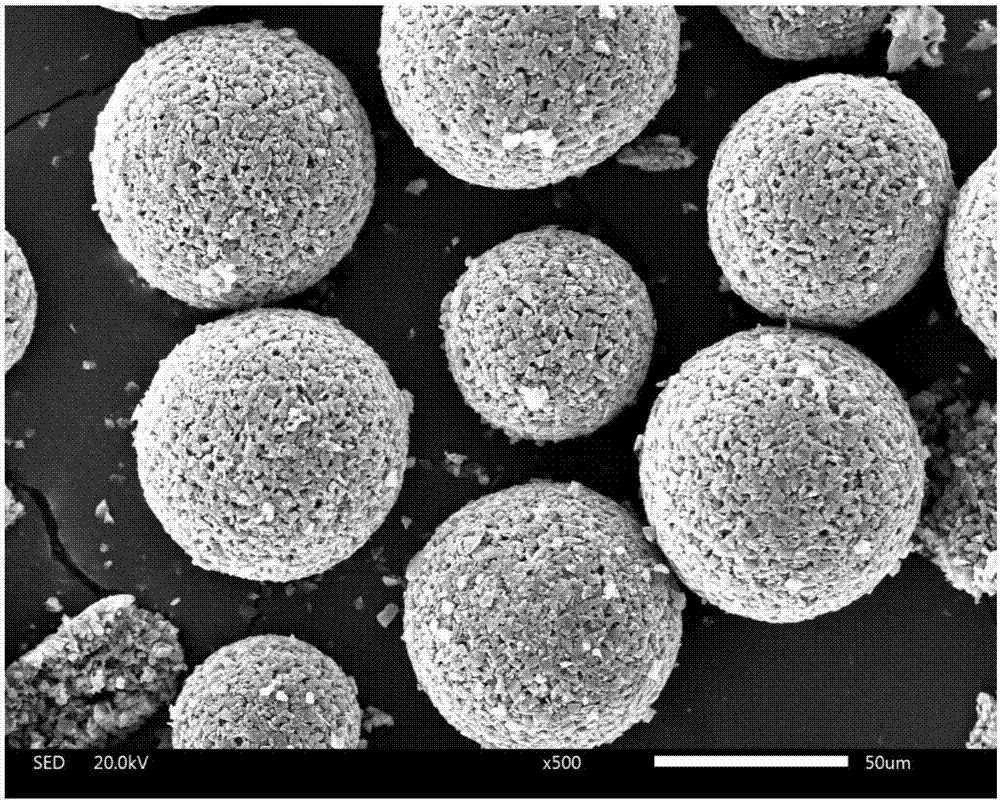

[0025] Put deionized water, lubricant A, glycerin, dispersant, binder A, and cyclodextrin in a polytetrafluoroethylene ball mill tank, add boron carbide balls and place them on a planetary ball mill for ball mill mixing. The ball-to-material ratio is 3:1, the ball milling speed is 300r / min, ball milling 0.5h, then add boron carbide micropowder into the ball milling jar, continue ball milling for 0.5h, then add water-soluble phenolic resin into the ball milling jar and mill for 12h, finally add propylene glycol into the ball milling jar Ball mill for 10 minutes to obtain slurry; the resulting slurry is dried and granulated with a spray drying granulator, and the inlet temperature of the spr...

Embodiment 2

[0028] Each raw material is batched according to the following mass percentages: boron carbide micropowder 20g (D 50 : 2.5~3.5μm), deionized water 18g, lubricant A 0.4g, glycerin 0.2g, dispersant 0.2g, binder A 1g, cyclodextrin 0.2g, water-soluble phenolic resin 2g, propylene glycol 0.02g;

[0029] Put deionized water, lubricant A, glycerin, dispersant, binder A, and cyclodextrin in a polytetrafluoroethylene ball mill tank, add boron carbide balls and place them on a planetary ball mill for ball mill mixing. The ball-to-material ratio is 4:1, ball milling speed is 300r / min, ball milling 0.5h, then add boron carbide micropowder into the ball milling jar, continue ball milling for 0.5h, then add water-soluble phenolic resin into the ball milling jar and mill for 18h, finally add propylene glycol into the ball milling jar Ball mill for 10 minutes to obtain slurry; the obtained slurry is dried and granulated with a spray drying granulator, and the inlet temperature of the spray dr...

Embodiment 3

[0032] Each raw material is batched according to the following mass percentages: boron carbide micropowder 20g (D 50 : 2.5~3.5μm), deionized water 15g, lubricant A 0.4g, glycerin 0.2g, dispersant 0.2g, binder A 1g, cyclodextrin 0.2g, water-soluble phenolic resin 2g, propylene glycol 0.02g;

[0033] Put deionized water, lubricant A, glycerin, dispersant, binder A, and cyclodextrin in a polytetrafluoroethylene ball mill tank, add boron carbide balls and place them on a planetary ball mill for ball mill mixing. The ball-to-material ratio is 4:1, ball milling speed is 300r / min, ball milling 0.5h, then add boron carbide micropowder into the ball milling jar, continue ball milling for 0.5h, then add water-soluble phenolic resin into the ball milling jar and mill for 18h, finally add propylene glycol into the ball milling jar Ball mill for 10 minutes to obtain slurry; the obtained slurry is dried and granulated with a spray drying granulator, and the inlet temperature of the spray dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of repose | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com