Device and method for preparing calcium alginate microspheres by using micro-reactor, and applications thereof

A calcium alginate, microreactor technology, applied in chemical instruments and methods, chemical/physical/physical-chemical reactors, pharmaceutical formulations, etc., can solve the problems of mutual adsorption of droplets, uneven flow rate, etc., and achieve uniform particle size. , The effect of large reaction area and controllable swelling ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

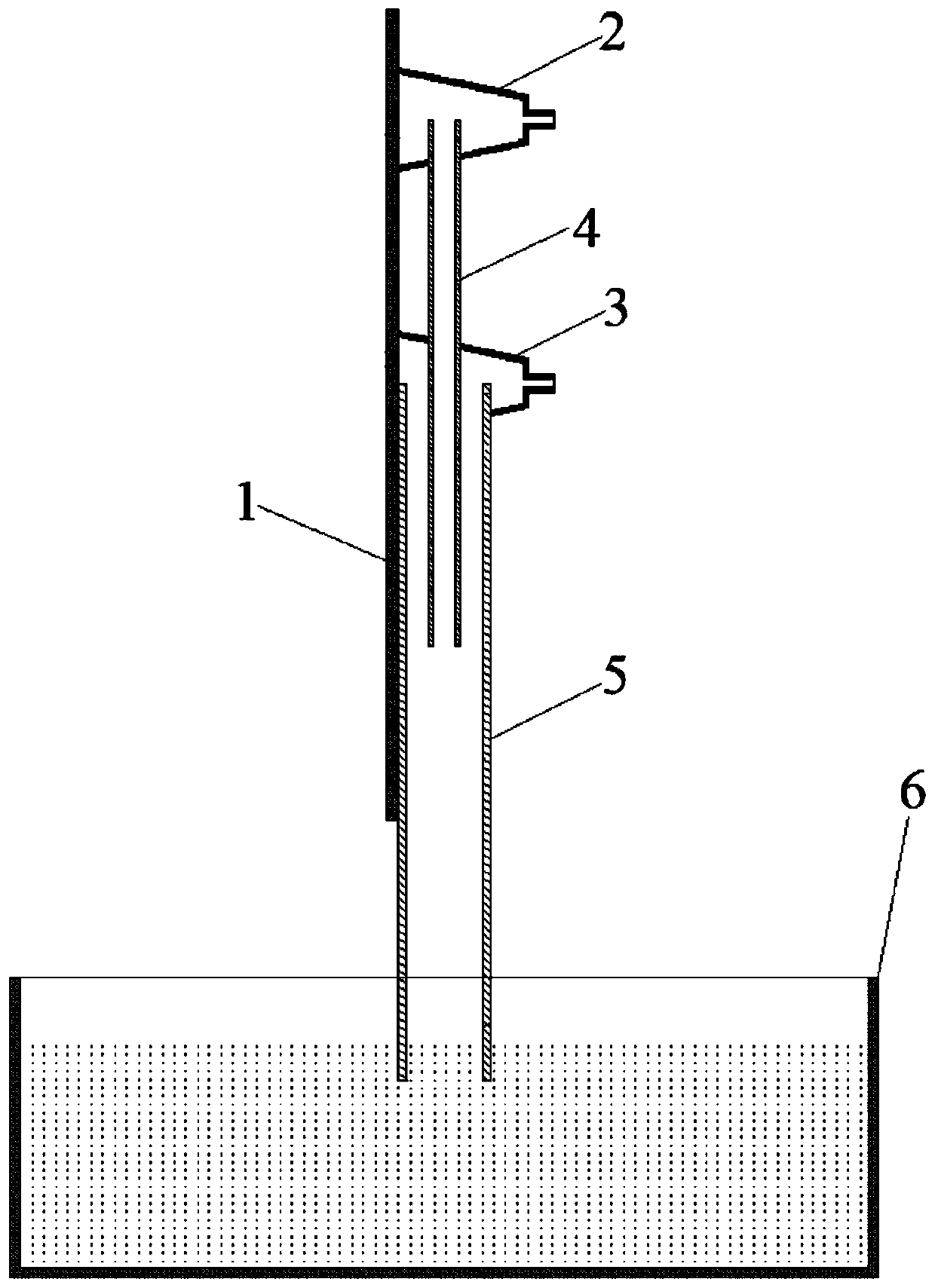

[0048] refer to figure 1 , an example of a device for preparing calcium alginate microspheres designed based on a microreactor in the present invention, including: a bottom plate 1, a first dispensing needle 2, a second dispensing needle 3, an inner phase glass tube 4, and an outer phase glass Tube 5 and collection culture dish 6; The first dispensing needle 2 and the second dispensing needle 3 are fixed side by side on the bottom plate 1, and a port of the inner phase glass tube 4 is connected with the cavity of the first dispensing needle 2 One port of the outer phase glass tube 5 communicates with the cavity of the second dispensing needle 3, and the other port of the inner phase glass tube 4 passes through the cavity of the second dispensing needle 3 and then extends into the outer phase glass In the tube 5 ; the other port of the outer phase glass tube 5 is located in the collection petri dish 6 , and the central axis of the outer phase glass tube 5 is perpendicular to th...

Embodiment 2

[0054] A device for preparing calcium alginate microspheres based on a microreactor, the same as in Example 1, the difference is that it also includes syringes for injecting the internal phase fluid and the external phase fluid respectively, the first dispensing needle 2, the second point The glue needles 3 are respectively connected with a syringe, and flow pumps are used to drive the respective syringes, so as to inject the inner phase fluid and the outer phase fluid into the first glue dispensing needle 2 and the second glue dispensing needle 3 respectively.

Embodiment 3

[0056] A device for preparing calcium alginate microspheres based on a microreactor, the same as in Example 2, the difference is that the bottom plate is a glass slide of the 7101 type, and the inner phase glass tube 4 and the outer phase glass tube 5 are both 100 mm in length A capillary glass tube, and the inner diameter of the inner glass tube 4 is 0.1 mm, and the inner diameter of the outer glass tube 5 is 0.5 mm. The inner phase glass tube 4 and the outer phase glass tube 5 are fixed together with the glass slide by gluing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com