Method for manufacturing high-grade artificial rutile by ilmenite concentrate

A technology of artificial rutile and ilmenite, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of too long reaction time, complicated process and equipment, etc., to reduce energy consumption, reduce equipment investment, and avoid solid-liquid Difficulty effects of separation and washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

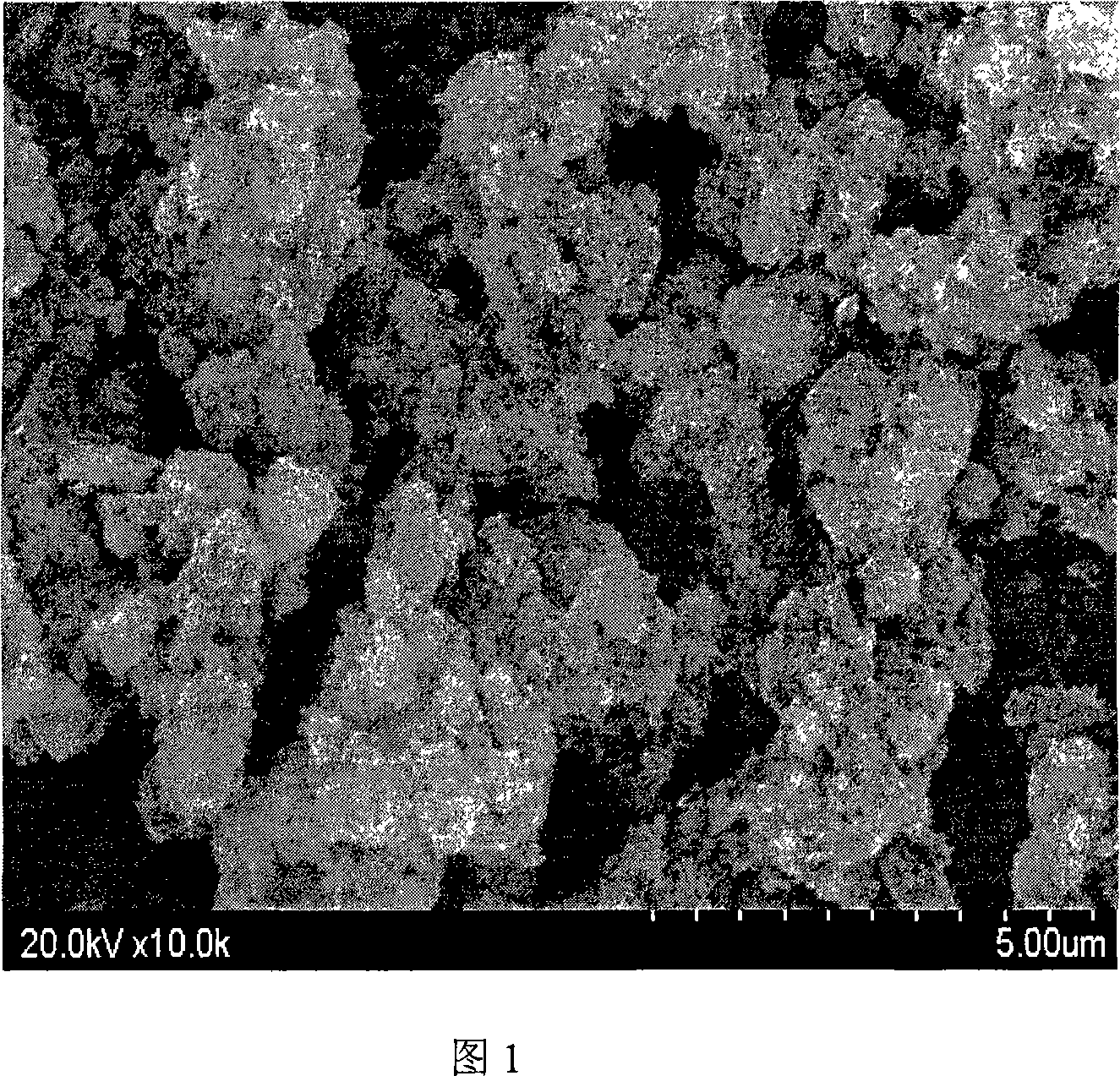

Image

Examples

Embodiment 1

[0028] In this embodiment, artificial rutile is produced as raw material with Panzhihuayan ore-type ilmenite concentrate (see Table 1 for chemical composition), and the process steps are as follows:

[0029] (1) ball mill activation

[0030] Put 200 grams of ilmenite concentrate in a planetary ball mill for ball mill activation, the ball-to-material ratio is 10:1, and the centrifugal acceleration of the ball is 180m / s 2 , the ball milling time is 20 minutes.

[0031] (2) Atmospheric pressure leaching

[0032] Take 100 grams of activated ilmenite and 500 ml of hydrochloric acid solution with a mass concentration of 15% and add them to the leaching kettle, and heat to 90°C under normal pressure to carry out the leaching reaction. The reaction time is 6 hours, and the dissolved titanium is hydrolyzed to generate an artificial rutile precursor. Impurities such as dissolved iron remain in the mother liquor.

[0033] (3) Solid-liquid separation

[0034] After the reaction is com...

Embodiment 2

[0044] In this embodiment, artificial rutile is produced as raw material with Panzhihuayan ore-type ilmenite concentrate (see Table 1 for chemical composition), and the process steps are as follows:

[0045] (1) ball mill activation

[0046] Put 200 grams of ilmenite concentrate in a planetary ball mill for ball mill activation, the ball-to-material ratio is 20:1, and the centrifugal acceleration of the ball is 100m / s 2 , the ball milling time is 15 minutes.

[0047] (2) Atmospheric pressure leaching

[0048]Take 100 grams of activated ilmenite and 400 ml of hydrochloric acid solution with a mass concentration of 20% and add them to the leaching kettle, and heat to 100°C under normal pressure for leaching reaction. The reaction time is 6 hours, and the dissolved titanium is hydrolyzed to generate an artificial rutile precursor. Impurities such as dissolved iron remain in the mother liquor.

[0049] (3) Solid-liquid separation

[0050] After the reaction is completed, cool ...

Embodiment 3

[0057] In this embodiment, artificial rutile is produced as raw material with Panzhihuayan ore-type ilmenite concentrate (see Table 1 for chemical composition), and the process steps are as follows:

[0058] (1) ball mill activation

[0059] Put 200 grams of ilmenite concentrate in a planetary ball mill for ball mill activation, the ball-to-material ratio is 30:1, and the centrifugal acceleration of the ball is 100m / s 2 , the ball milling time is 10 minutes.

[0060] (2) Atmospheric pressure leaching

[0061] Take 100 grams of activated ilmenite and 300 ml of hydrochloric acid solution with a mass concentration of 25% and add it to the leaching kettle, and heat it to 105°C under normal pressure to carry out the leaching reaction. The reaction time is 4 hours, and the dissolved titanium is hydrolyzed to generate an artificial rutile precursor. Impurities such as dissolved iron remain in the mother liquor.

[0062] (3) Solid-liquid separation

[0063] After the reaction is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com