Nano-silicon dioxide hollow sphere material and method of preparing the same

A technology of nano-silica and hollow spheres, applied in the field of nano-materials, can solve problems that hinder practical use, and achieve the effects of simple operation, good adsorption, and simple reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

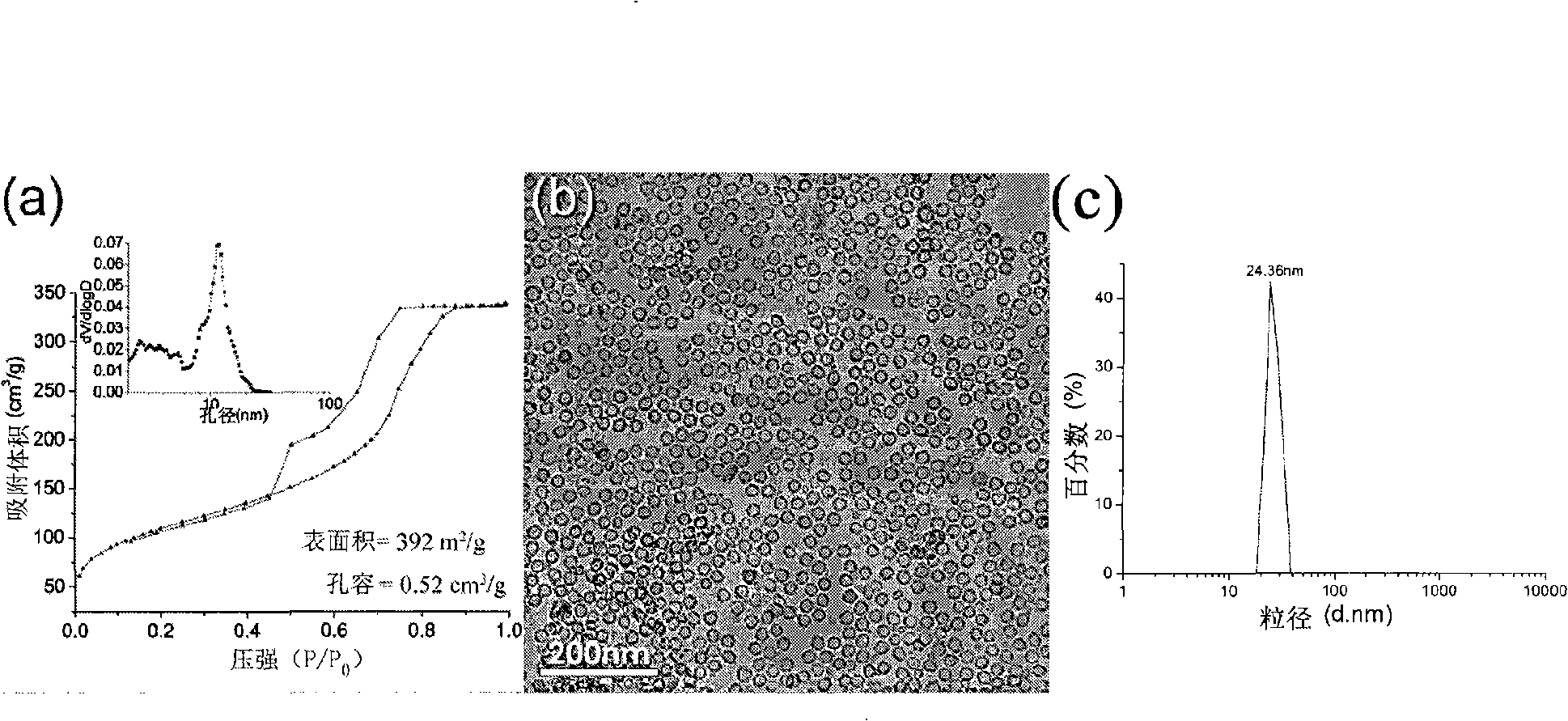

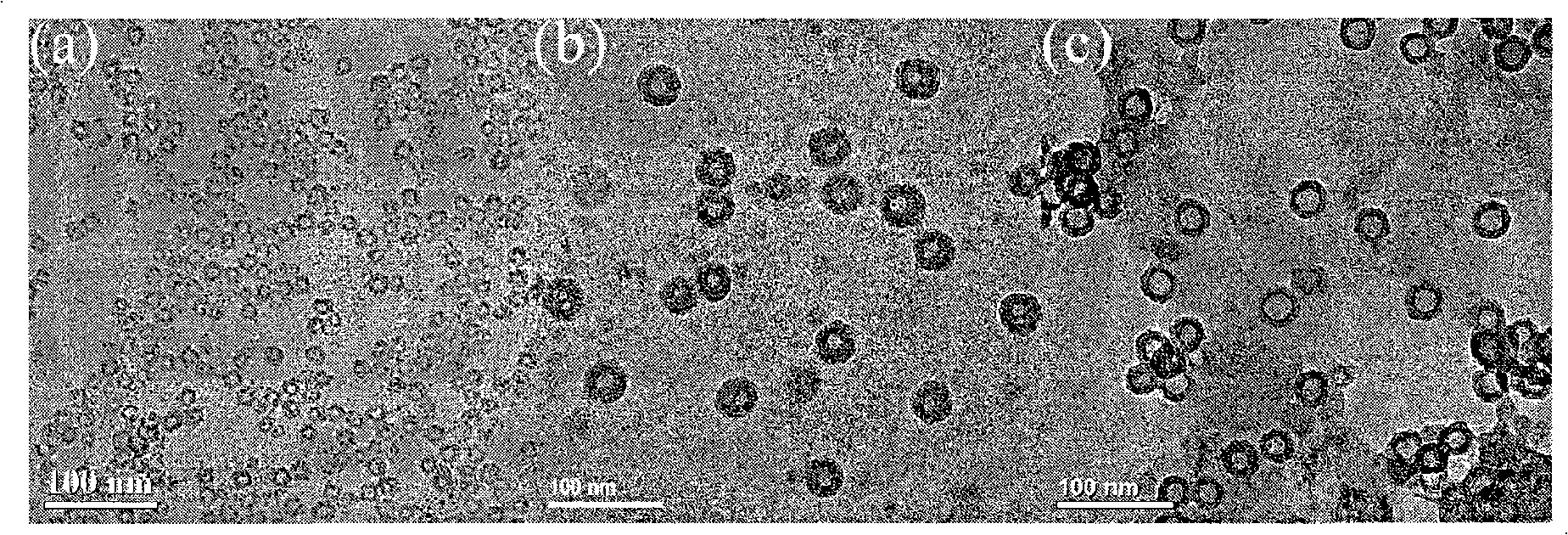

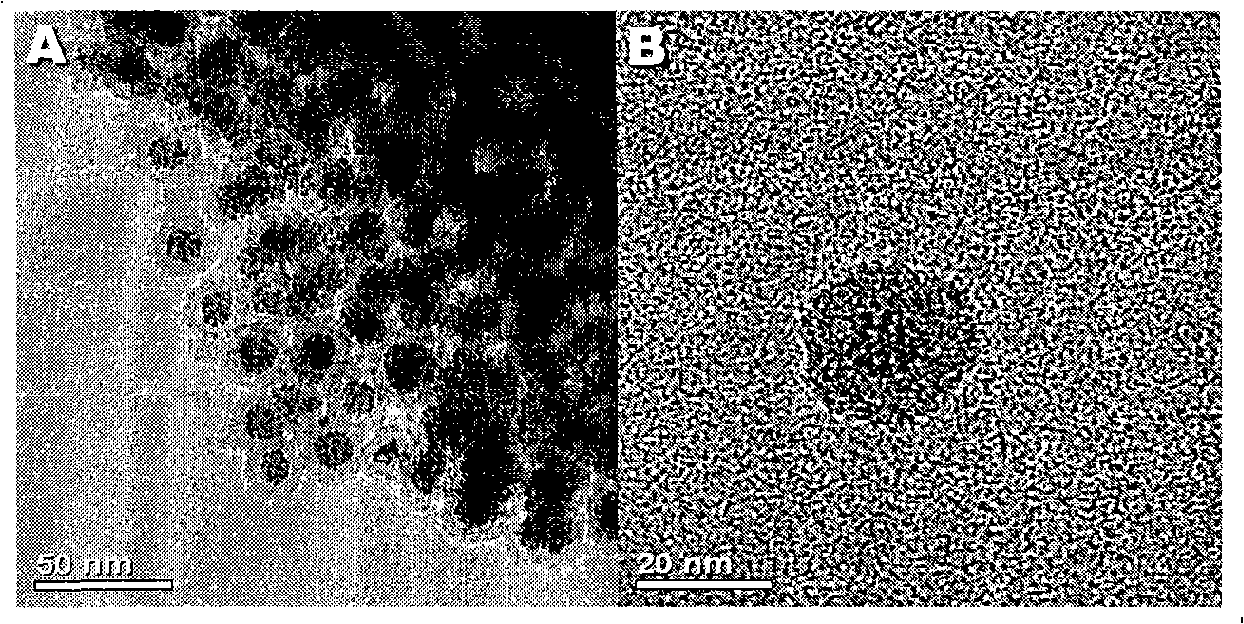

Embodiment 1

[0028] Dissolve 1.0g of F108 and 1.0g of 1,3,5-trimethylbenzene in 30mL of 2M hydrochloric acid system under stirring at 25°C in a constant temperature circulating water bath. After stirring for more than 6 hours to form a milky white milky liquid homogeneous system, add 1.0g of TEOS , after stirring for 6 h, 0.5 mL of dimethyl dimethyl silicate (DMDMS, (CH 3 ) 2 Si(CH 3 O) 2 ) and continued constant temperature stirring for 48h. The resulting liquid was poured into a dialysis membrane with a molecular weight cut off of 14000, put into distilled water and repeatedly replaced with distilled water (once every 6 h) for dialysis for two days. After dialysis, the solution that removes hydrochloric acid or other inorganic ions is dried in an oven at 100°C. The obtained massive solid was calcined at 350° C. for 6 hours to remove the surfactant to obtain a nano-silica hollow sphere material.

Embodiment 2

[0030] Under the condition of constant temperature circulating water bath at 20°C, stir and dissolve 1.0g F108 and 0.5g 1,3,5-trimethylbenzene in 30mL 1M hydrochloric acid system, stir for more than 6h to form a milky white milky liquid homogeneous system, add 1.5g TEOS, After stirring for 12 h, 0.75 mL of dimethyl dimethyl silicate (DMDMS, (CH 3 ) 2 Si(CH 3 O) 2 ) and continued constant temperature stirring for 48h. The resulting liquid was poured into a dialysis membrane with a molecular weight cut off of 14000, put into distilled water and repeatedly replaced with distilled water (once every 6 h) for dialysis for two days. After dialysis, the solution that removes hydrochloric acid or other inorganic ions is dried in an oven at 100°C, and then redissolved in 30mL of 10% H 2 o 2 , adjust the pH to about 3.5, place it in a quartz jacketed beaker, use 25°C circulating water to control the temperature, use two ultraviolet lights with a wavelength of 253nm and a power of 15...

Embodiment 3

[0032] Under the condition of constant temperature circulating water bath at 40℃, stir and dissolve 1.0g F108 and 1.0g TMB in 30mL 0.5M hydrochloric acid system, stir for more than 6h to form a milky white milky liquid homogeneous system, add 1.0g TMOS, stir for 6h, then add 1.0 mL of dimethyl dimethyl silicate (DMDMS, (CH 3 ) 2 Si(CH 3 O) 2 ) and continued constant temperature stirring for 48h. The resulting liquid was poured into a dialysis membrane with a molecular weight cut off of 14000, put into distilled water and repeatedly replaced with distilled water (once every 6 h) for dialysis for two days. After dialysis, the solution that removes hydrochloric acid or other inorganic ions is dried in an oven at 100°C, and then redissolved in 30 mL of 15% H 2 o 2 , adjust the pH value to 3.5, place it in a 100°C oven for 16 hours, and dry the obtained product in an oven at 100°C to obtain a nano-silica hollow sphere material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com