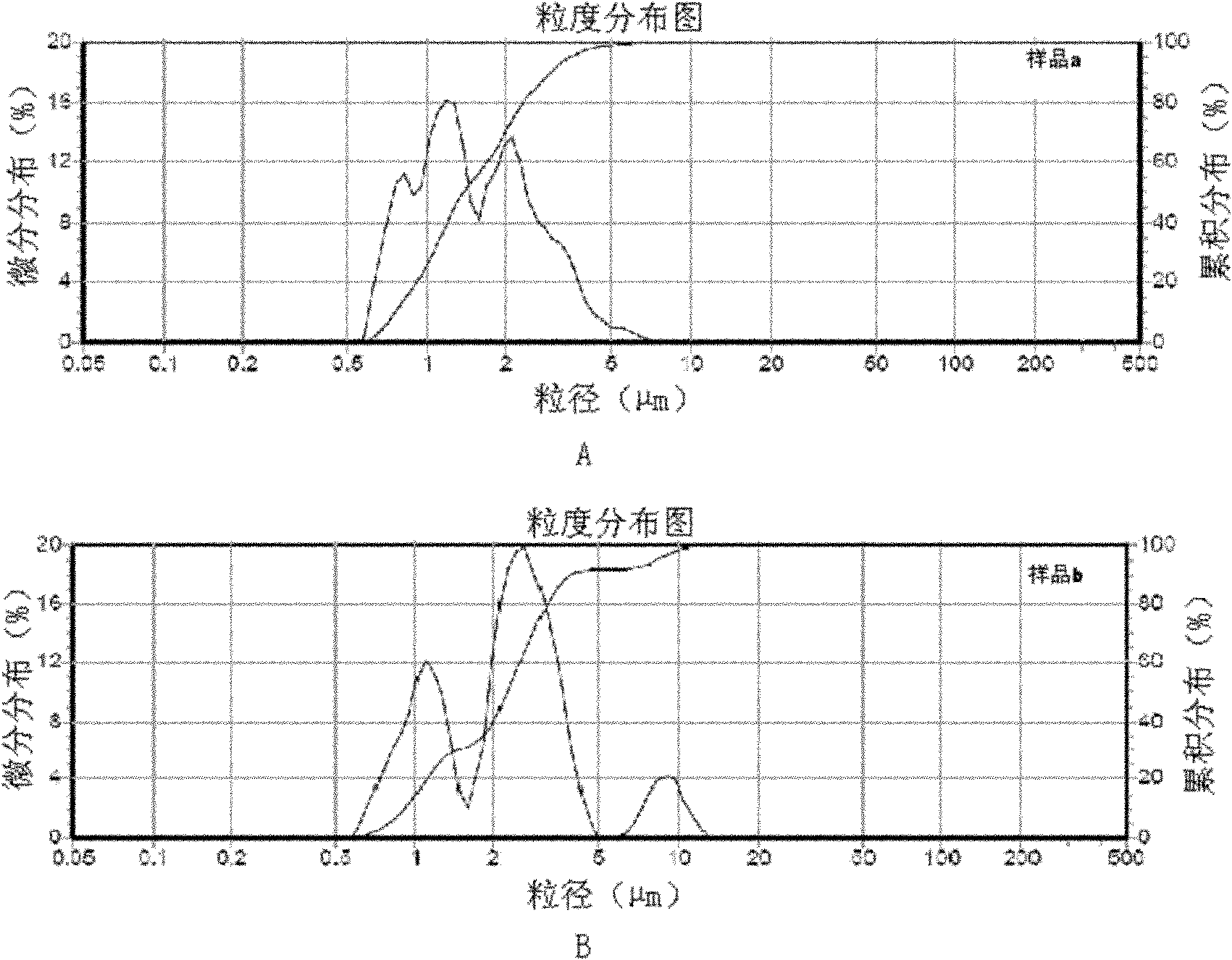

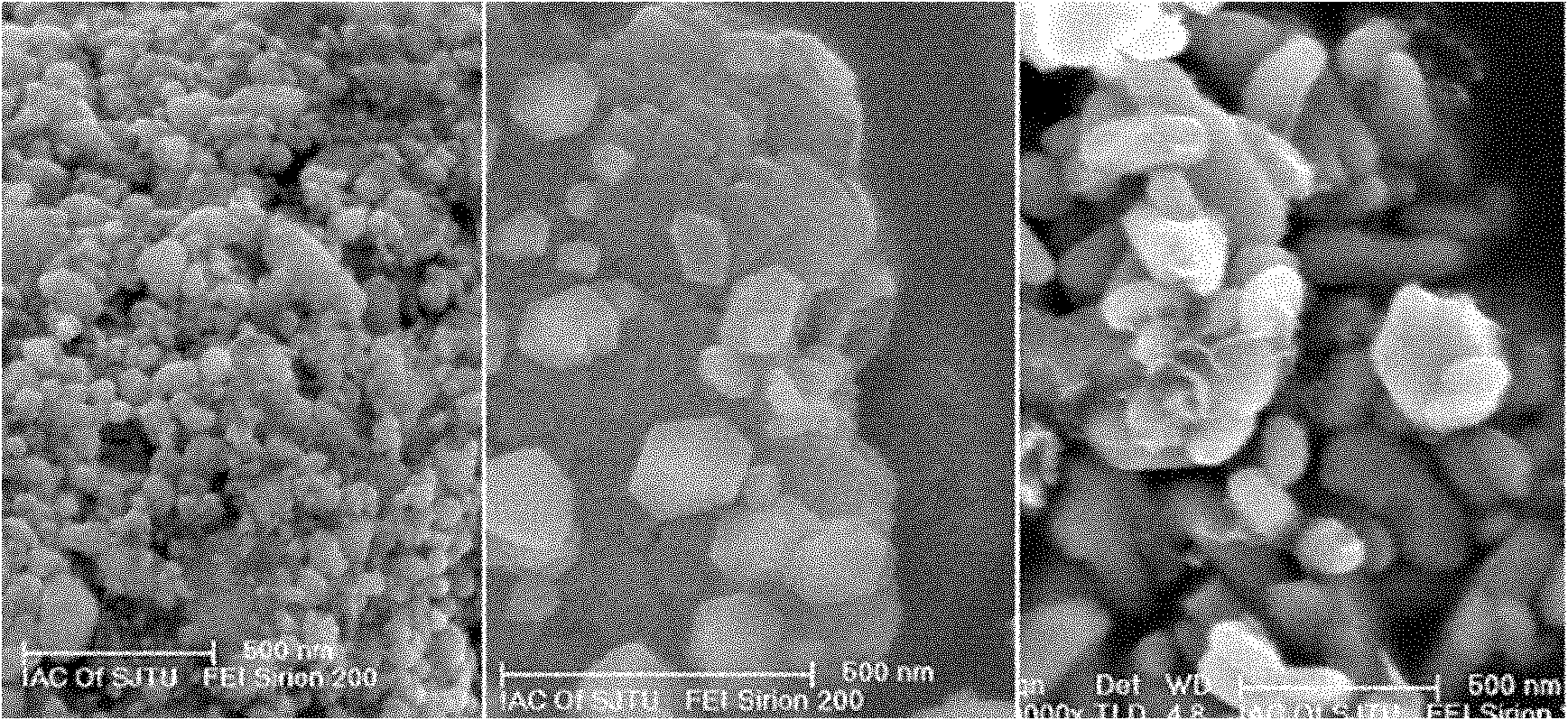

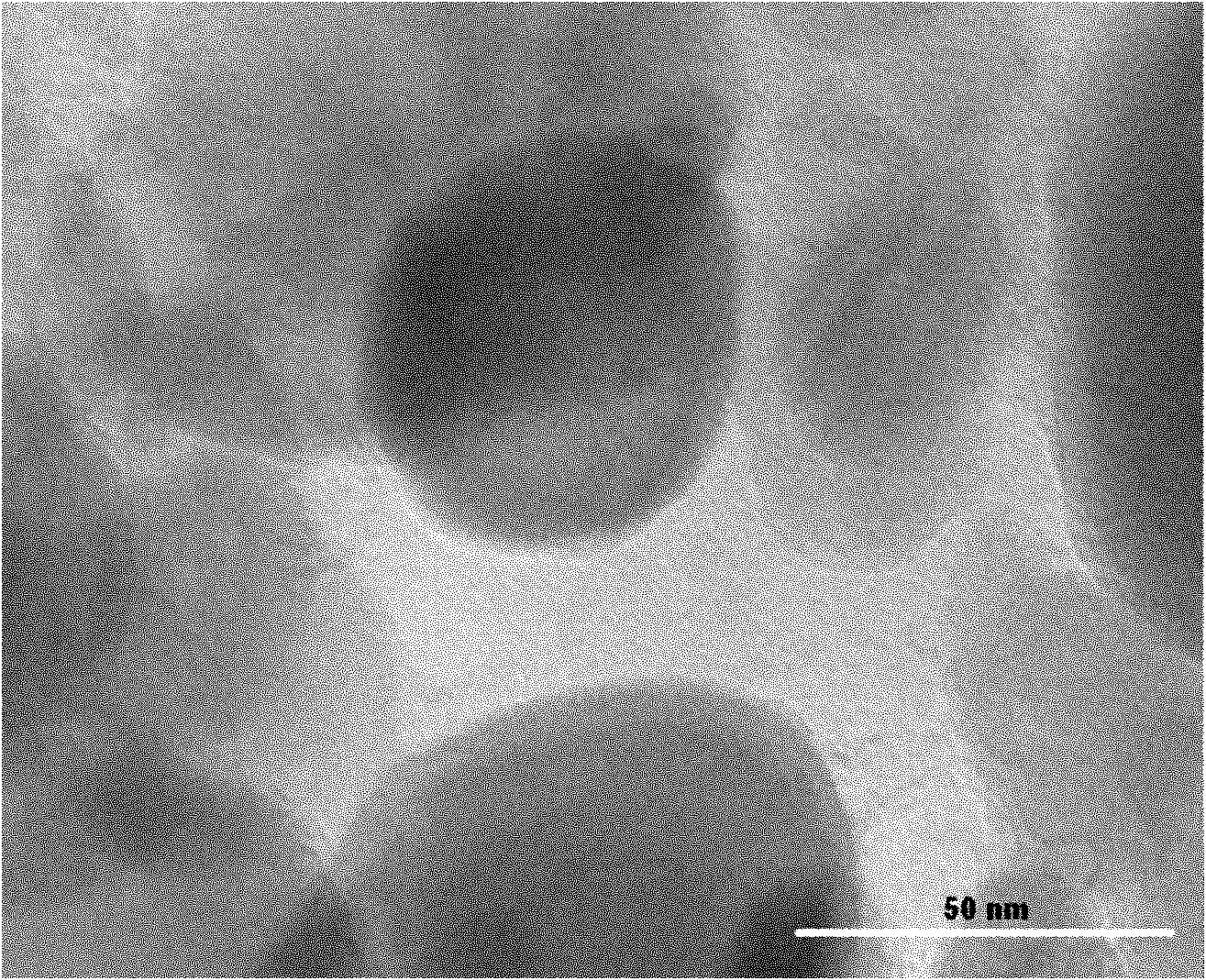

Lithium ion phosphate positive electrode material of nanometer core shell structure and preparation method thereof

A positive electrode material, lithium iron phosphate technology, applied in the direction of structural parts, battery electrodes, electrical components, etc., can solve the problems of uneven materials, reduced compaction density, and reduced powder processing and use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] With Fe(NO 3 ) 3 9H 2 O. Li 3 PO 4 , NH 4 h 2 PO 4 It is the raw material of positive electrode material, and citric acid C6H8O7 is used as the precursor of porous carbon structure and nano-carbon layer. The ratio of lithium source, iron source, phosphorus source and citric acid is according to Li:Fe:P:citric acid=1:1:1 : 5 (molar ratio) for weighing, Fe(NO 3 ) 3 9H 2 O 1.212kg (about 3mol), Li 3 PO 4 0.12kg (about 1mol), NH 4 h 2 PO 4 0.230kg (about 2mol), citric acid 1kg (about 5mol), mix well and control the order of addition (dissolve the ammonium salt NH first 4 h 2 PO 4 , citric acid C6H8O7), then add 10L-20L deionized water, stir vigorously for 10-90min, then add Fe(NO 3 ) 3 9H 2 O. Li 3 PO 4 The mixed solution was fully stirred and dissolved to obtain a reddish-brown transparent solution. Use an appropriate amount of ammonia water to adjust the pH to 1, then place the solution in an electric blast oven, and dry it at 150°C for 3 hours to ...

Embodiment 2

[0043] With Fe(NO 3 ) 3 9H 2 O, LiOH·H 2 O, NH 4 h 2 PO 4 As the raw material of the positive electrode material, Al(NO 3 ) 3 9H 2 O is the precursor of the porous structure. Experiments were carried out with citric acid C6H8O7 and ethylene glycol as the precursor of the nano-carbon layer. The ratio of lithium source, iron source, phosphorus source, aluminum source and citric acid is weighed according to Li: Fe: P: Al: citric acid = 1: 0.95: 0.05: 5 (molar ratio), Fe(NO 3 ) 3 9H 2 O 1.212kg (about 3mol), LiOH·H 2 O0.36kg (about 3mol), NH 4 h 2 PO 4 0.345kg (about 3mol), Al(NO 3 ) 3 9H 2 O 0.056kg (about 0.015mol), citric acid 0.9kg (about 4.4mol), mix well and control the order of addition (dissolve the ammonium salt NH first 4 h 2 PO 4 , citric acid C6H8O7), then add 10L-20L deionized water, stir vigorously for 10-90min, then add Fe(NO 3 ) 3 9H 2 O, LiOH·H 2 O, Al(NO 3 )3 9H 2 The mixed solution of O was fully stirred and dissolved to obtain a reddi...

Embodiment 3

[0047] FePO 4 2H 2 O. Li 2 CO 3 As raw material, control Li:Fe:P molar ratio to 1:1:1, weigh FePO 4 2H 2 O0.370kg (about 2mol), weigh Li 2 CO 3 0.220kg (about 1mol), typically 35%, with 1.2kg of ethanol as a solvent, add 180g of commercial carbon airgel that is fully pulverized, add surfactants, 50g of oleic acid, 10g of PVA (polyvinyl alcohol), ethylene glycol Alcohol 50g, after high-speed dispersion, let it stand for 30 minutes to fully impregnate the slurry and airgel, and the impregnation time is controlled at 30 minutes. After the impregnation process is completed, the pH value of the slurry is adjusted to 6, and the suspension system is destroyed and separated into layers. After pouring and separating the solvent, it is dried by electric heating at 50 degrees for 8 hours, and the mixture is calcined. Place it in an atmosphere furnace for high-temperature calcination, the protective atmosphere is 3L / min of high-purity nitrogen, the heating rate is 10°C / min, and it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com