Preparation method of methyl phenyl silicone oil

A technology of methyl phenyl silicone oil and diphenyl dichlorosilane is applied in the field of preparation of dimethyl diphenyl silicone oil to achieve the effects of reducing environmental pollution, mild reaction conditions and large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

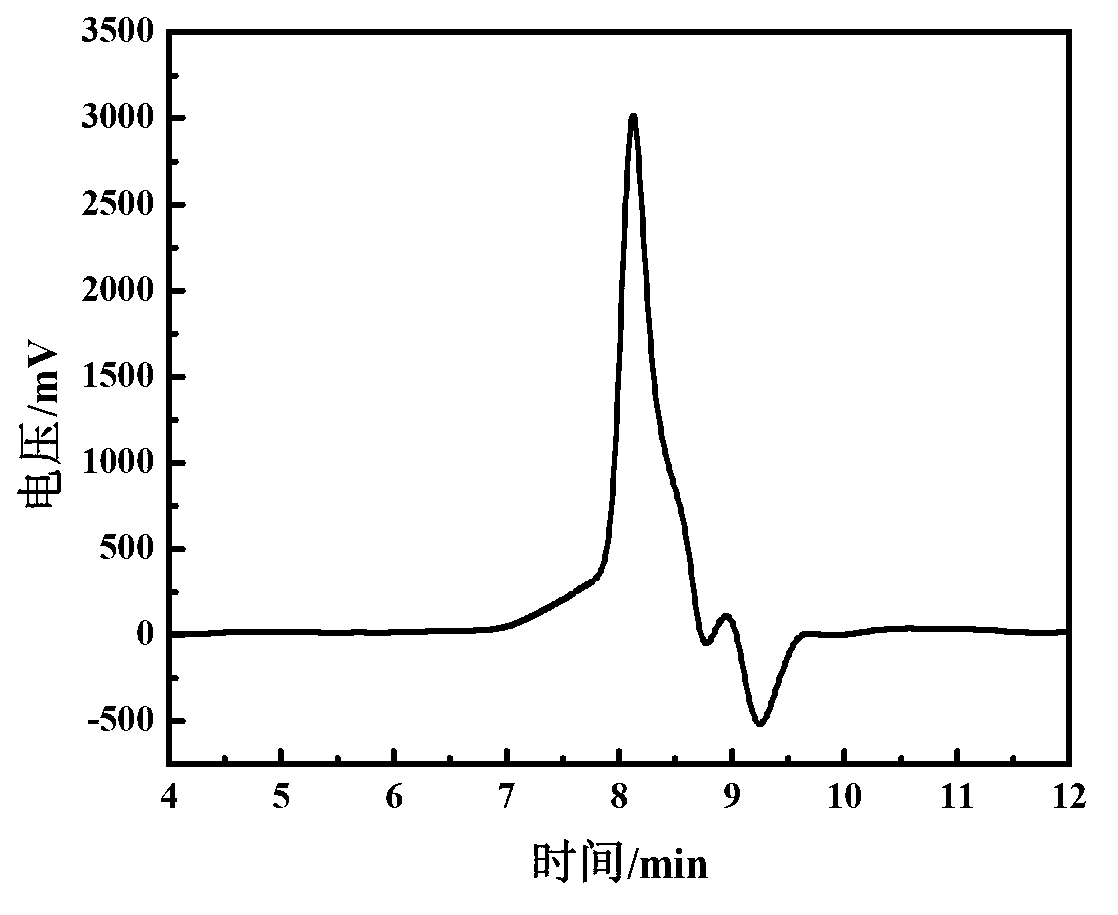

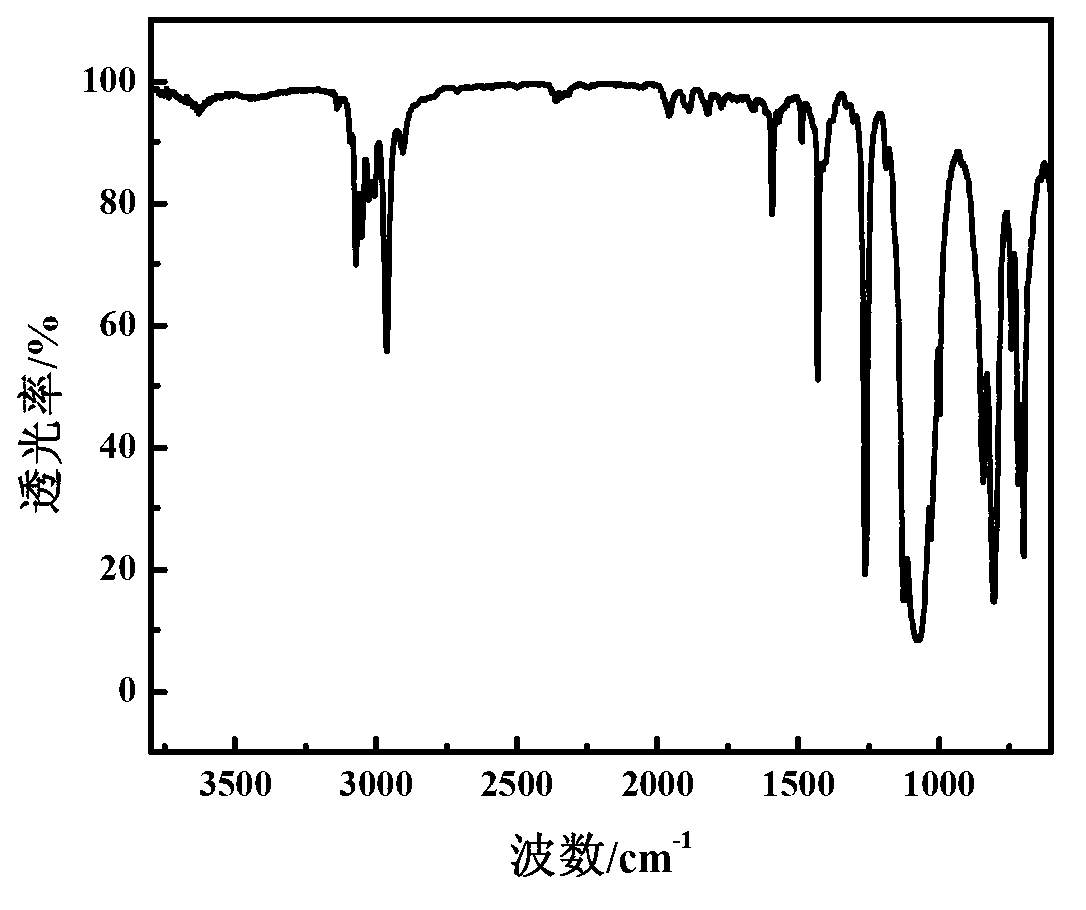

[0029] The Ph / R ratio (molar ratio) was 0.1. Add 80 mL of xylene, 50 mL of acetone, 23.23 g of dimethyldichlorosilane and 5.06 g of diphenyldichlorosilane into a 500 mL three-neck flask, stir and mix evenly at 30 °C; prepare a certain proportion of hydrolyzate, of which Acetone 100 mL and distilled water 57.6 g, stir evenly, add drop by drop to the three-necked flask with a constant pressure titration funnel, control the dropping rate to keep 1d / 2s, the total titration time is about 3 h, add 0.5432 g capped Chlorotrimethylsilane, continue to react at 30°C for 5h, and the hydrolysis is completed; stand for stratification, separate the lower layer of acid water, wash the upper layer of hydrolyzate with distilled water at 50-60°C until neutral, and obtain a siloxane prepolymer , and then add 0.0570 g of condensation catalyst sodium ethylate (0.05% of the total mass of the monomer) at 100 °C for condensation reaction for 3 h. The solvent xylene and low boilers were distilled off ...

Embodiment 2

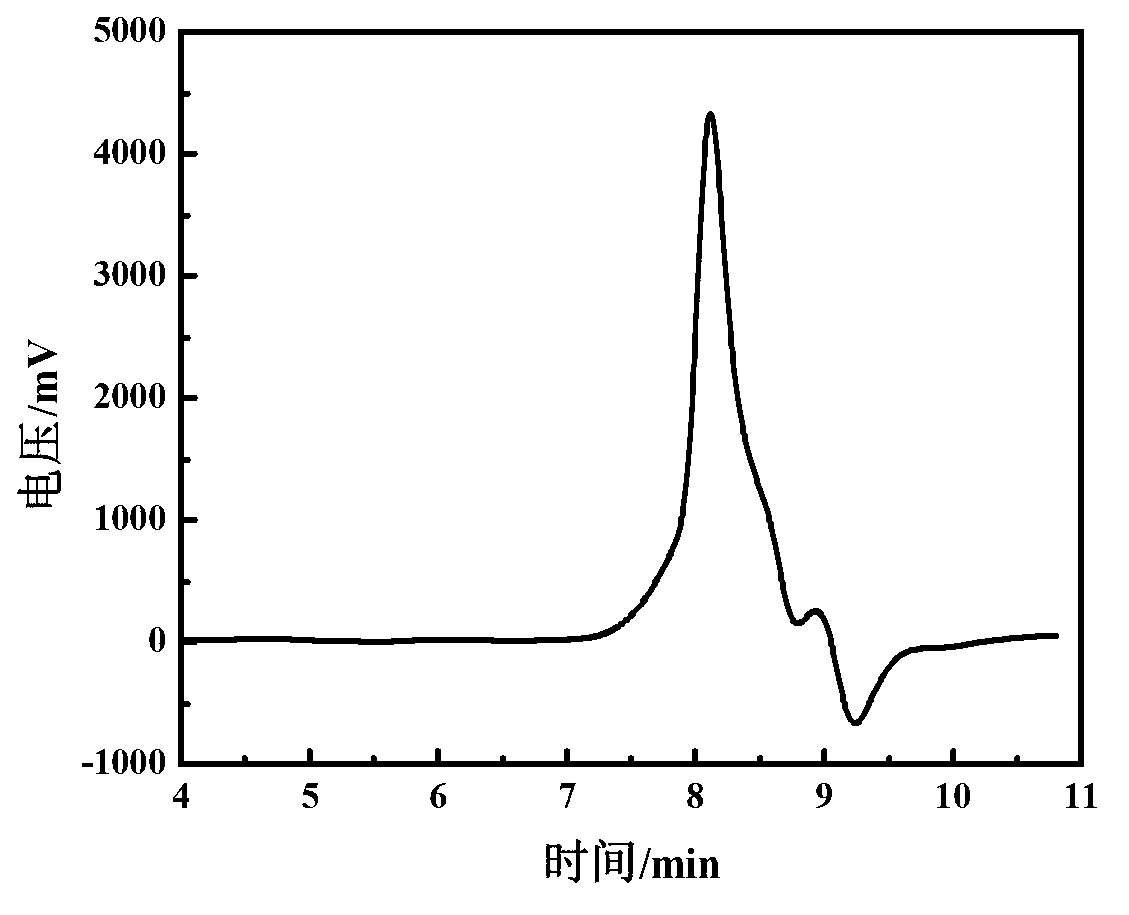

[0031] The Ph / R ratio (molar ratio) was 0.3. Add 80 mL of xylene, 50 mL of acetone, 18.07 g of dimethyldichlorosilane and 15.19 g of diphenyldichlorosilane into a 500 mL three-necked flask, and stir and mix evenly at 30 °C; prepare a certain proportion of hydrolyzate, of which Acetone 100 mL and distilled water 57.6 g, stir evenly, add drop by drop to the three-necked flask with a constant pressure titration funnel, control the dropping rate to keep 1d / 2s, the total titration time is about 3 h, add 0.5432 g capped Chlorotrimethylsilane, continue to react at 30°C for 5h, and the hydrolysis is completed; stand for stratification, separate the lower layer of acid water, wash the upper layer of hydrolyzate with distilled water at 50-60°C until neutral, and obtain a siloxane prepolymer , and then add 0.0665 g of condensation catalyst sodium ethylate (0.05% of the total monomer mass) at 100 °C for condensation reaction for 3 h. The solvent xylene and low boilers were distilled off ...

Embodiment 3

[0033] The Ph / R ratio (molar ratio) was 0.7. Add 80 mL of xylene, 50 mL of acetone, 7.74 g of dimethyldichlorosilane and 35.45 g of diphenyldichlorosilane into a 500 mL three-neck flask, stir and mix evenly at 30 °C; prepare a certain proportion of hydrolyzate, of which Acetone 100 mL and distilled water 57.6 g, stir evenly, add drop by drop to the three-necked flask with a constant pressure titration funnel, control the dropping rate to keep 1d / 2s, the total titration time is about 3 h, add 0.5432 g capped Chlorotrimethylsilane, continue to react at 30°C for 5h, and the hydrolysis is completed; stand for stratification, separate the lower layer of acid water, wash the upper layer of hydrolyzate with distilled water at 50-60°C until neutral, and obtain a siloxane prepolymer , and then add 0.0864 g of condensation catalyst sodium ethylate (0.05% of the total monomer mass) at 100 °C for condensation reaction for 3 h. The solvent xylene and low boilers were distilled off under r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com