Preparation method of polyethyleneglycol monomethyl ether-polylactic acid block copolymer

A technology of polyethylene glycol monomethyl ether and block copolymer, which is applied in the directions of non-active ingredients medical preparations, medical preparations containing active ingredients, and pharmaceutical formulas, which can solve the problems of easy agglomeration, solvent residue, large Impurities and other problems, to achieve the effect of good fluidity, reduced molecular weight distribution, and improved hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

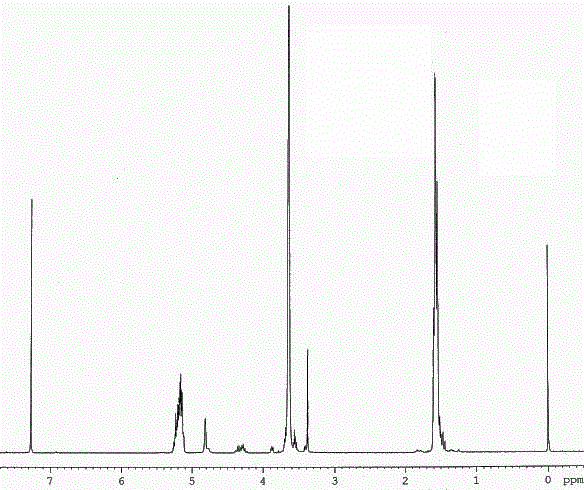

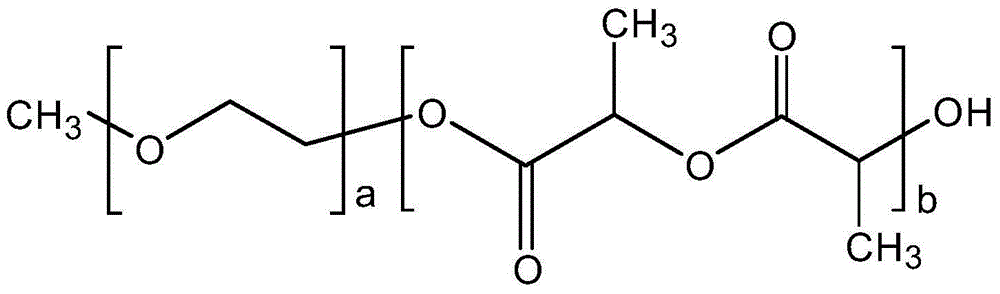

Image

Examples

Embodiment 1

[0036] Reaction stage: put 192g of polyethylene glycol monomethyl ether into the reactor, replace it with nitrogen, and dry it in vacuum at 120°C for 3 hours, then put 1.2g of the catalyst stannous octoate into the reactor, replace it with nitrogen, and continue vacuum drying for 1 hour; put in lactide 208g, evacuate for 1.5min, airtight, after the lactide is completely melted, then evacuate for 5min, heat up to 140°C, react for 12h, after the reaction is completed, cool down to obtain a light yellow clear liquid;

[0037] The first crystallization: dilute with 400ml of dichloromethane, slowly add to 8L of ether, stir and crystallize for 1h, and filter with suction;

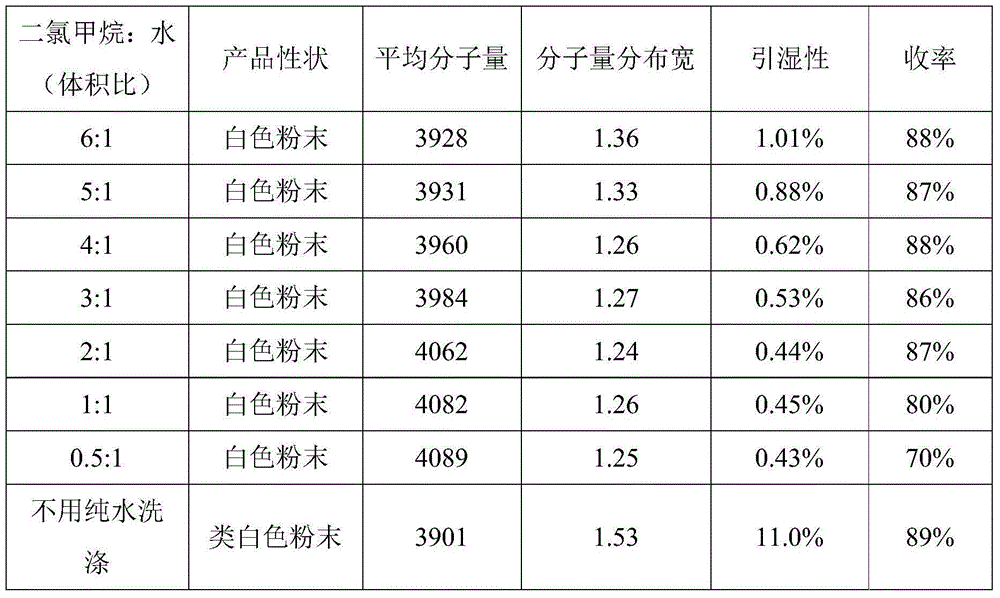

[0038] The second crystallization: dilute the filter cake with 1600ml of dichloromethane, wash with 800ml of purified water, dry with 200g of anhydrous magnesium sulfate, filter with suction, remove the dichloromethane by rotary evaporation of the mother liquor, add 200ml of dichloromethane to dissolve, add to 6L ...

Embodiment 2

[0043] Reaction stage: put 192g of polyethylene glycol monomethyl ether into the reactor, replace it with nitrogen, and dry it in vacuum at 120°C for 3 hours, then put 1.2g of the catalyst stannous octoate into the reactor, replace it with nitrogen, and continue vacuum drying for 1 hour; put in lactide 208g, evacuate for 1.5min, airtight, after the lactide is completely melted, then evacuate for 5min, heat up to 140°C, react for 12h, after the reaction is completed, cool down to obtain a light yellow clear liquid;

[0044] The first crystallization: add 3L of dichloromethane to the reaction solution for dilution, wash with 1.5L of purified water, dry with 300g of anhydrous magnesium sulfate, filter with suction, remove the dichloromethane by rotary evaporation of the mother liquor, add 200ml of dichloromethane to dissolve, add to In 6L of ether at 0±5°C, stir and crystallize for 1h, and filter with suction;

[0045] The second crystallization: add 200ml of dichloromethane to t...

Embodiment 3

[0049] Reaction stage: put 192g of polyethylene glycol monomethyl ether into the reactor, replace it with nitrogen, and dry it in vacuum at 120°C for 3 hours, then put 1.2g of the catalyst stannous octoate into the reactor, replace it with nitrogen, and continue vacuum drying for 1 hour; put in lactide 208g, evacuate for 1.5min, airtight, after the lactide is completely melted, then evacuate for 5min, heat up to 140°C, react for 12h, after the reaction is completed, cool down to obtain a light yellow clear liquid;

[0050] The first crystallization: add 200ml of dichloromethane to dilute, slowly add to 6L 0±5°C ether, stir and crystallize for 1h, and filter with suction; the second crystallization: add 1000ml of dichloromethane to dissolve the filter cake, wash with 500ml of purified water, Dry 200g of anhydrous magnesium sulfate, filter with suction, remove dichloromethane by rotary evaporation of the mother liquor, then add 200ml of dichloromethane to dissolve, add to 6L of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com