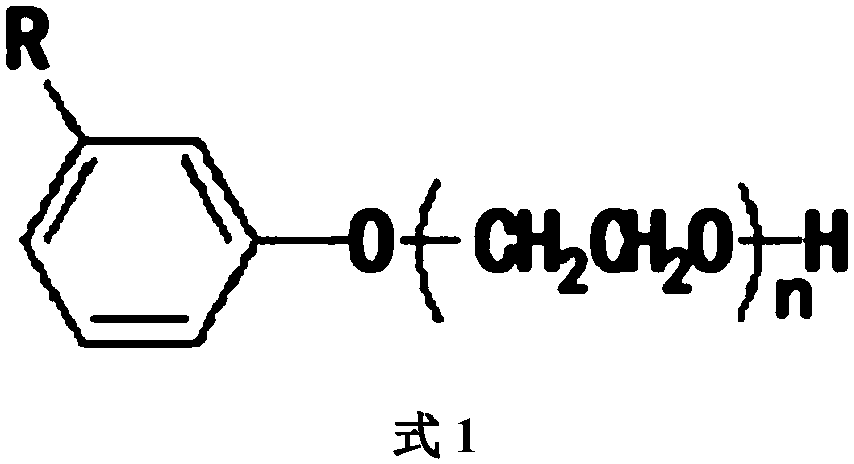

Method for preparing cardanol polyoxyethylene ether

A technology of cardanol polyoxyethylene ether and cardanol, which is applied in the preparation of ether from alkylene oxide, ether preparation, organic chemistry, etc. It can solve the problems of internal quality factors such as product molecular weight distribution, etc., and achieve a stable and controllable reaction , mild process conditions, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

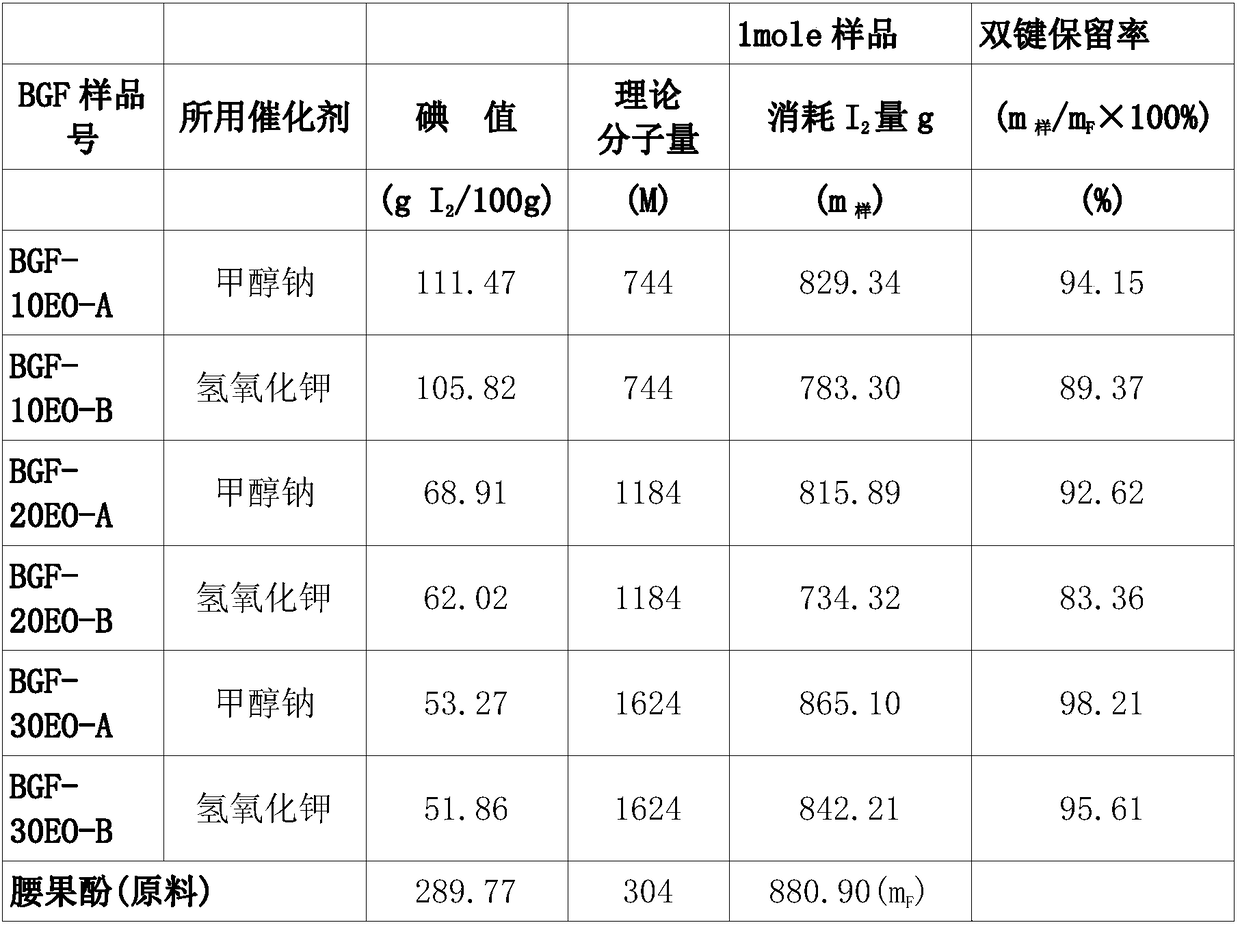

[0014] Embodiment 1 (preparation of BGF-10EO-A)

[0015] 304 grams of cardanol and 1.116 grams of sodium methoxide were put into the autoclave, and then the air in the autoclave was replaced by nitrogen filling and vacuuming for 3 times. Heat the material under stirring, and dehydrate it under vacuum at 90-120°C for 45min. Then start adding ethylene oxide under negative pressure, maintain the reaction temperature at 130-165°C, and pressure -0.08-0.26MPa, and finish adding 440 grams of ethylene oxide within 2.5 hours. Then carry out aging reaction 50MIN. to negative pressure in the kettle. Then remove the residual gas in the kettle at 125°C and -0.08MPa vacuum. Cool down to 80°C and add 1.9 g of lactic acid to neutralize the material to pH ~ 6, and discharge to obtain 734 g of product BGF-10EO-A.

Embodiment 2

[0016] Embodiment 2 (preparation of BGF-20EO-A)

[0017] 250 grams of cardanol and 1.5 grams of sodium methylate were dropped into the autoclave, and then the air in the autoclave was replaced by nitrogen filling and vacuuming for 3 times. Heat the material under stirring, and dehydrate it under vacuum at 90-120°C for 45min. Then start adding ethylene oxide under negative pressure, maintain the reaction temperature at 130-165°C, and pressure -0.08-0.25MPa, and finish adding 735 grams of ethylene oxide within 2.5 hours. Then carry out aging and heat preservation reaction for 1h to negative pressure in the kettle. Then remove the residual gas in the kettle at 125°C and -0.08MPa vacuum. Cool down to 80°C and add 2.5 grams of lactic acid to neutralize the material to pH ~ 6, and discharge to obtain 976 grams of product BGF-20EO-A.

Embodiment 3

[0018] Embodiment 3 (preparation of BGF-30EO-A)

[0019] 220 grams of cardanol and 1.8 grams of sodium ethylate were dropped into the autoclave, and then the air in the autoclave was replaced by nitrogen filling and vacuuming for 3 times. Heat the material under stirring, and dehydrate it under vacuum at 90-120°C for 45min. Then start adding ethylene oxide under negative pressure, maintain the reaction temperature at 130-165°C, and pressure -0.08-0.24MPa, and finish adding 968 grams of ethylene oxide within 3.0 hours. Then carry out aging and heat preservation reaction for 1h to negative pressure in the kettle. Then remove the residual gas in the kettle at 125°C and -0.08MPa vacuum. Cool down to 85°C and add 2.4 grams of lactic acid to neutralize the material until slightly acidic, and discharge to obtain 1178 grams of the product BGF-30EO-A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com