High-strength antiflaming polyester industrial filaments and preparation method thereof

A technology of flame retardant polyester and industrial yarn, which is applied in the manufacture of fire-retardant and flame-retardant filaments, single-component polyester rayon, etc. Low strength and other problems, to achieve excellent viscosity increase effect, large melting enthalpy value, high melting point effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

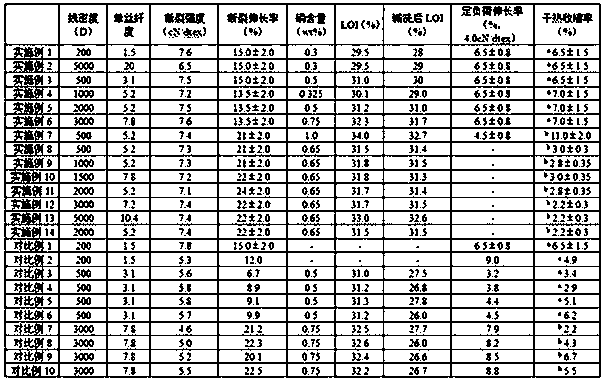

Examples

preparation example Construction

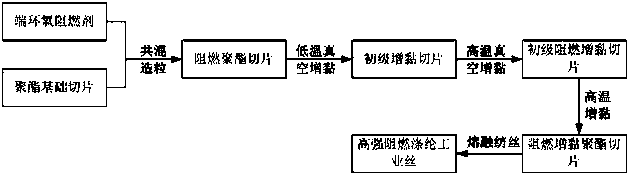

[0038] A kind of preparation method of high-strength flame-retardant polyester industrial yarn, it comprises the following steps,

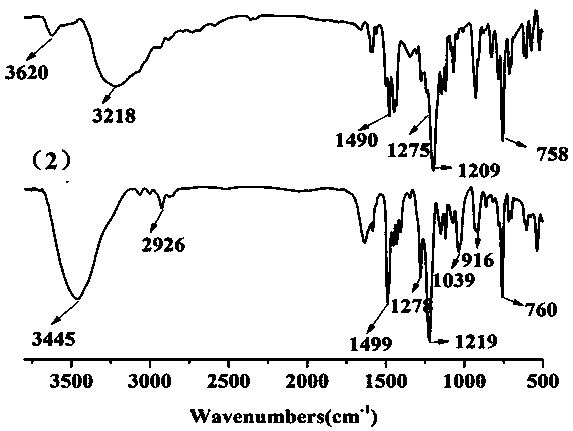

[0039] (1) Preparation of terminal epoxy flame retardant

[0040] According to a certain ratio, the phosphorus-containing flame retardant 10-(2,5-dihydroxyphenyl)-10-hydrogen-9-oxa-10-phosphaphenanthrene-10-oxide (ODOPB) and epichlorohydrin Mix, then add the catalyst benzyltriethylammonium chloride and react at 80-90°C for 60-90 minutes, then add NaOH aqueous solution, stir at room temperature for 30-45 minutes, and then add ethyl acetate and water after the reaction The mixed solvent is extracted to obtain the organic phase, then dried with anhydrous sodium sulfate, and the ethyl acetate is removed by the method of pressure distillation to prepare the terminated epoxy flame retardant, the melting point of the described epoxy terminated flame retardant is 165~168℃.

[0041] The mol ratio of described ODOPB and epichlorohydrin is 1:2; The mass fr...

Embodiment 2

[0058] A kind of preparation method of high-strength flame-retardant polyester industrial yarn, it comprises the following steps,

[0059] (1) Preparation of terminal epoxy flame retardant

[0060] According to a certain ratio, the phosphorus-containing flame retardant 10-(2,5-dihydroxyphenyl)-10-hydrogen-9-oxa-10-phosphaphenanthrene-10-oxide (ODOPB) and epichlorohydrin Mix, then add the catalyst benzyltriethylammonium chloride and react at 80-90°C for 60-90 minutes, then add NaOH aqueous solution, stir at room temperature for 30-45 minutes, and then add ethyl acetate and water after the reaction The mixed solvent is extracted to obtain the organic phase, then dried with anhydrous sodium sulfate, and the ethyl acetate is removed by the method of pressure distillation to prepare the terminated epoxy flame retardant, the melting point of the described epoxy terminated flame retardant is 165~168℃.

[0061] The mol ratio of described ODOPB and epichlorohydrin is 1:10; The massfr...

Embodiment 3

[0078] A kind of preparation method of high-strength flame-retardant polyester industrial yarn, it comprises the following steps,

[0079] (1) Preparation of terminal epoxy flame retardant

[0080] According to a certain ratio, the phosphorus-containing flame retardant 10-(2,5-dihydroxyphenyl)-10-hydrogen-9-oxa-10-phosphaphenanthrene-10-oxide (ODOPB) and epichlorohydrin Mix, then add the catalyst benzyltriethylammonium chloride and react at 80-90°C for 60-90 minutes, then add NaOH aqueous solution, stir at room temperature for 30-45 minutes, and then add ethyl acetate and water after the reaction The mixed solvent is extracted to obtain the organic phase, then dried with anhydrous sodium sulfate, and the ethyl acetate is removed by the method of pressure distillation to prepare the terminated epoxy flame retardant, the melting point of the described epoxy terminated flame retardant is 165~168℃.

[0081] The mol ratio of described ODOPB and epichlorohydrin is 1:5; The mass fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com