Preparation method of methyl phenyl silicone oil with high refractive index

A technology of methyl phenyl silicone oil and high refractive index is applied in the field of preparation of high refractive index methyl phenyl silicone oil to achieve the effects of good uniformity, high catalytic activity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

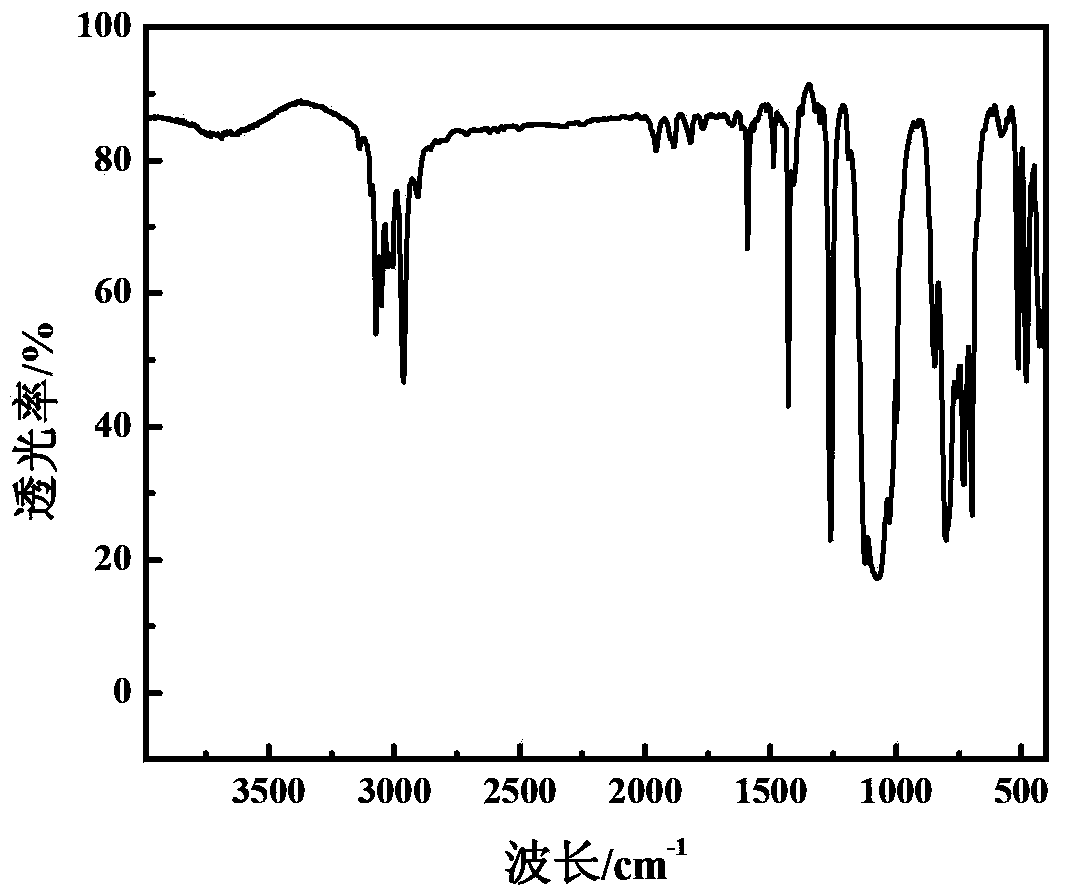

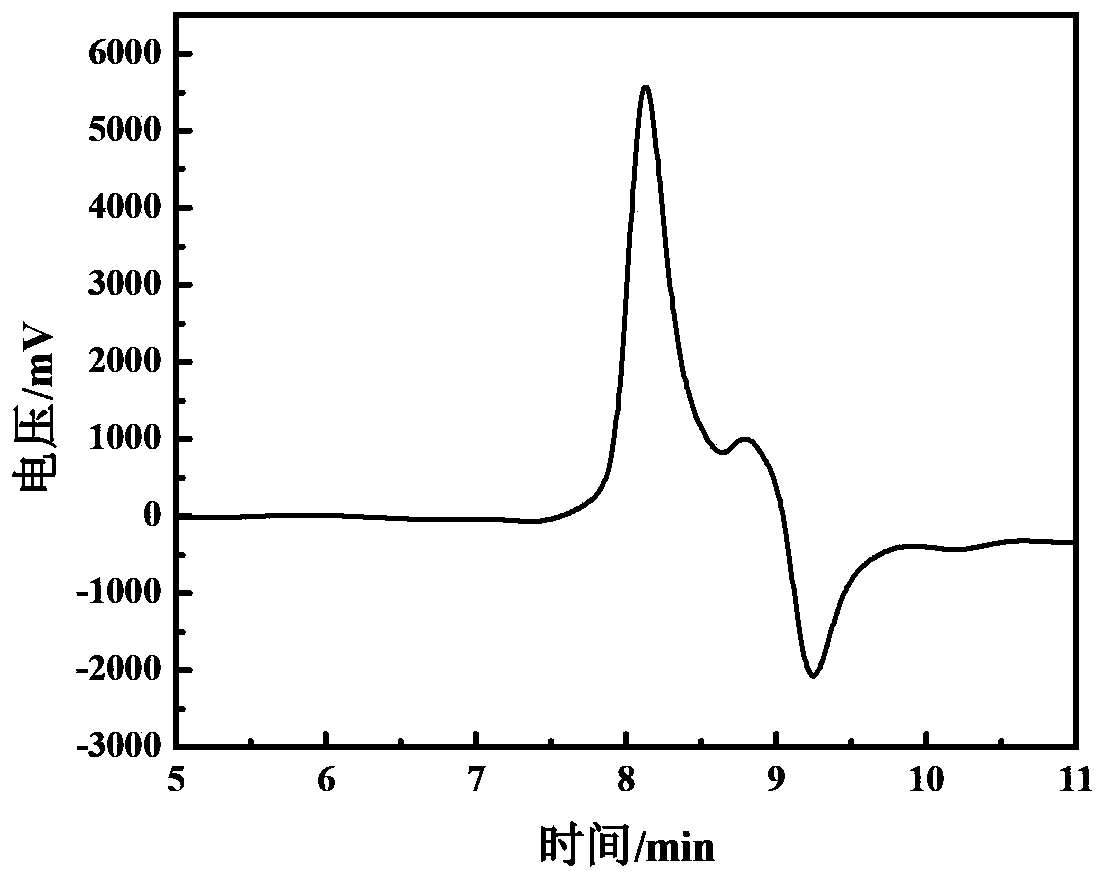

Image

Examples

Embodiment 1

[0028] The Ph / R ratio (molar ratio) was 0.35. Add 80 mL of xylene, 50 mL of acetone, 10.32 g of dimethyldichlorosilane, 19.11 g of methylphenyldichlorosilane, and 5.06 g of diphenyldichlorosilane into a 500 mL three-neck flask, stir and mix at 30 °C Uniform; add 100 mL of acetone and 57.6 g of distilled water to the three-necked flask drop by drop with a constant pressure titration funnel. Continue the reaction for 10 h, and the hydrolysis is completed; let stand to separate the layers, separate the lower layer of acid water, and wash the upper layer of hydrolyzate with distilled water at 50-60 °C until neutral to obtain a siloxane prepolymer, and then add 0.811 g of six Methyldisiloxane and 0.3450 g condensation catalyst stannous octoate (the mass is 1% of the total mass of the monomers) were subjected to condensation reaction for 4 h. After the reaction, the catalyst was washed away with distilled water at 50-60 °C until it was neutral, and then at 130 The solvent xylene an...

Embodiment 2

[0030] The Ph / R ratio (molar ratio) was 0.55. Add 80 mL of xylene, 50 mL of acetone, 5.16 g of dimethyldichlorosilane, 19.11 g of methylphenyldichlorosilane, and 15.19 g of diphenyldichlorosilane into a 500 mL three-neck flask, stir and mix at 30 °C Uniform; add 100 mL of acetone and 57.6 g of distilled water to the three-necked flask drop by drop with a constant pressure titration funnel. Continue the reaction for 10 h, and the hydrolysis is completed; let stand to separate the layers, separate the lower layer of acid water, and wash the upper layer of hydrolyzate with distilled water at 50-60 °C until neutral to obtain a siloxane prepolymer, and then add 0.811 g of six Methyldisiloxane and 0.3947 g condensation catalyst stannous octoate (mass is 1% of the total monomer mass) were subjected to condensation reaction for 4 h. After the reaction, the catalyst was washed with distilled water at 50-60 °C until it was neutral, and then at 130 The solvent xylene and low boilers wer...

Embodiment 3

[0032] The Ph / R ratio (molar ratio) was 0.65. Add 80 mL of xylene, 50 mL of acetone, 2.58 g of dimethyldichlorosilane, 19.11 g of methylphenyldichlorosilane, and 20.26 g of diphenyldichlorosilane into a 500 mL three-neck flask, stir and mix at 30 °C Uniform; add 100 mL of acetone and 57.6 g of distilled water to the three-necked flask drop by drop with a constant pressure titration funnel. Continue the reaction for 10 h, and the hydrolysis is completed; let stand to separate the layers, separate the lower layer of acid water, wash the upper layer of hydrolyzate with distilled water at 50-60 °C until neutral to obtain a siloxane prepolymer, and then add 0.811g of six at 100 °C Methyldisiloxane and 0.4195 g condensation catalyst stannous octoate (the mass is 1% of the total mass of the monomers) were subjected to condensation reaction for 4 h. After the reaction, the catalyst was washed with distilled water at 50-60 °C until it was neutral, and then at 130 The solvent xylene an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com