Aqueous UV (ultraviolet)-curable fluorine-alcohol-modified epoxy resin coating and preparation method thereof

A technology of epoxy resin coating and epoxy resin, applied in the direction of epoxy resin coating, coating, etc., can solve the problems of light curing efficiency, slow coating curing speed, high curing temperature, etc., and achieve high UV curing efficiency and molecular weight The effect of small distribution and precise and controllable fluorine content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

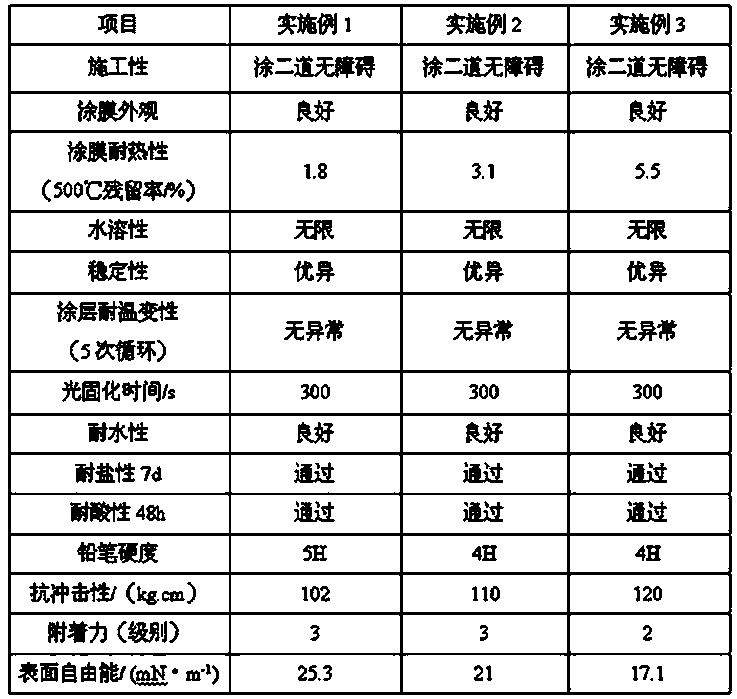

Examples

Embodiment 1

[0030] A waterborne UV curable fluoroalcohol modified epoxy resin coating (F n -EMA) and its preparation method, including the following steps:

[0031] S1. Preparation of monoisocyanate-terminated fluorinated isocyanate

[0032] According to the quantity of the substance, 1 part of 2,4-toluene diisocyanate, 1 part of heptafluorobutanol, 1 part of solvent 1,4-dioxane, 0.3wt% of catalyst dibutyl tin dilaurate, Place it in a four-necked flask filled with nitrogen and equipped with a thermometer, a condenser, and a stirring rod. The temperature is controlled to 20°C by heating in an oil bath, and the reaction is stirred for 3 hours, the reaction is stopped, and it is kept for use.

[0033] S2. Side chain fluorine-containing epoxy resin (F n -EP) Preparation

[0034] The resin prepared in step S1 was slowly added dropwise to 1.1 parts of E-44 epoxy resin dissolved in the solvent butyl acetate under the protection of nitrogen, stirred for 30 minutes, the temperature was...

Embodiment 2

[0040] A waterborne UV curable fluoroalcohol modified epoxy resin coating (F n -EMA) and its preparation method, including the following steps:

[0041] S1. Preparation of monoisocyanate-terminated fluorinated isocyanate

[0042] According to the quantity of the substance, place 1 part of 2,4-toluene diisocyanate, 1 part of nonafluorooctanol, 1 part of solvent butyl acetate, 0.3wt% catalyst stannous octoate, and place them in a nitrogen gas and pack In a four-necked flask with a thermometer, a condenser, and a stirring rod, the temperature is controlled to 20°C by heating in an oil bath, and the reaction is stirred for 3 hours, the reaction is stopped, and the reaction is kept for use.

[0043] S2. Side chain fluorine-containing epoxy resin (F n -EP) Preparation

[0044] The resin prepared in step S1, under the protection of nitrogen, was slowly added dropwise to 1.1 parts of E-44 epoxy resin dissolved in the solvent 1,4-dioxane. After stirring for 30 minutes, the tem...

Embodiment 3

[0050] A water-based UV curable fluoroalcohol modified epoxy resin coating (F n -EMA) and its preparation method, including the following steps:

[0051] S1. Preparation of monoisocyanate-terminated fluorinated isocyanate

[0052] According to the quantity of the substance, 1 part of 2,4-toluene diisocyanate, 1 part of tridecafluorooctanol, 1 part of solvent 1,4-dioxane, 0.3wt% of catalyst dibutyltin dilaurate , Placed in a four-necked flask filled with nitrogen and equipped with a thermometer, a condenser, and a stirring rod, heated in an oil bath to control the temperature to 20°C, stirred and reacted for 3 hours, stopped the reaction, and stood still for standby.

[0053] S2. Side chain fluorine-containing epoxy resin (F n -EP) Preparation

[0054] The resin prepared in step S1, under the protection of nitrogen, was slowly added dropwise to 1.1 parts of E-44 epoxy resin dissolved in the solvent 1,4-dioxane. After stirring for 30 minutes, the temperature was rais...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com