Polyethylene catalyst component with narrow molecular weight distribution, preparation method and application

A narrow molecular weight distribution and catalyst technology, which is applied in the fields of narrow molecular weight distribution polyethylene catalyst components, preparation and application, can solve the problems of high loading cost, low catalyst activity, reduction and other problems, and achieves low molecular weight distribution and high bulk density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

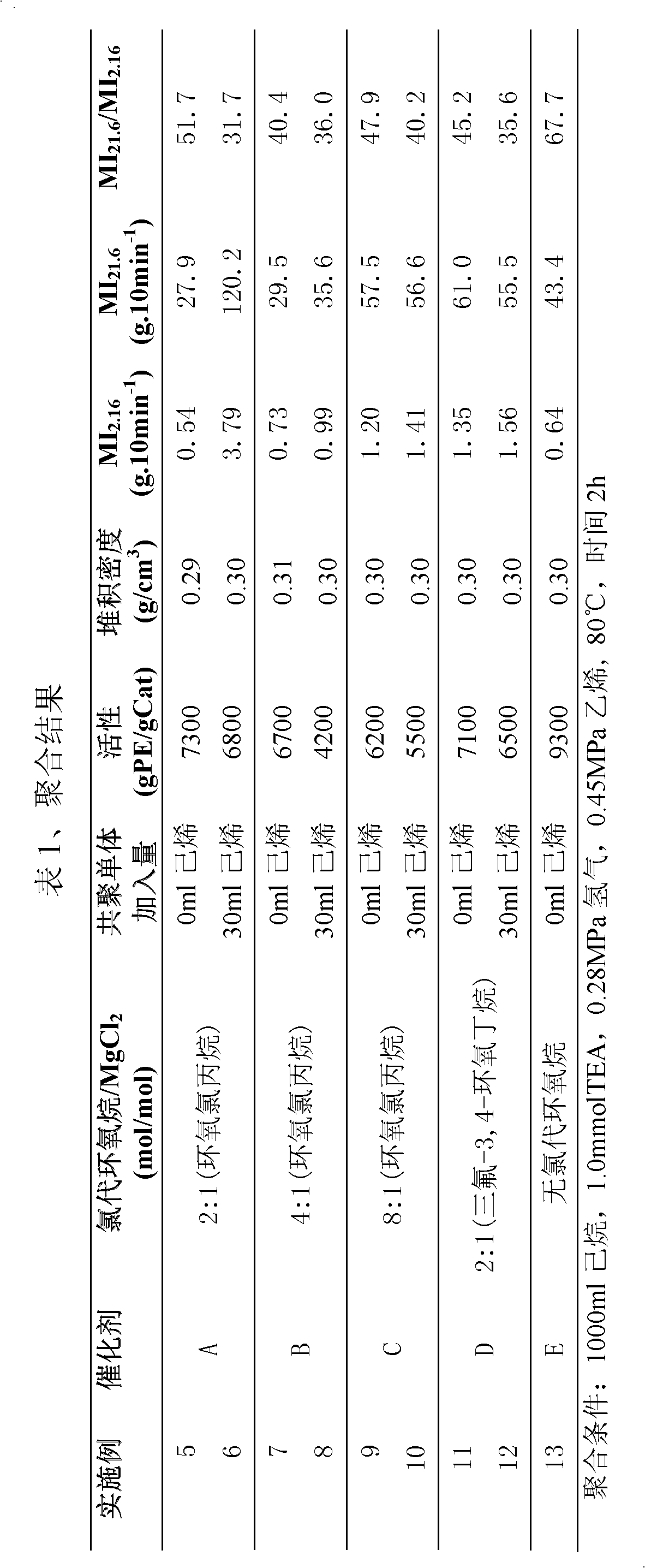

Examples

Embodiment 1

[0056] 1) Preparation of magnesium chloride / silica gel carrier (prepared according to the method of Chinese patent application 200710176589)

[0057] Under nitrogen protection, in a glass reactor, add 1.04 grams of anhydrous magnesium chloride at room temperature, then add 700 milliliters of dried tetrahydrofuran, start stirring, and 2.42 grams of silica gel (GRACESylopol 2485, under nitrogen, roast at 150 ° C for 2.5 hours, heat up to 300°C for 2 hours, then at 600°C for 5 hours) into the reactor, heated to 65°C, stirred and dissolved for 2 hours, then evaporated at 80°C to remove the solvent to obtain a white solid powder. The white solid powder was vacuum-dried at 100° C. for 2 hours, and then vacuum-dried at 300° C. for 10 hours to obtain 3.40 g of solid powder with good fluidity. According to gas chromatography analysis, no tetrahydrofuran was detected.

[0058] 2), the preparation of catalyst component A

[0059] 0.683 grams (2.15mmolMgCl) of magnesium chloride / silica g...

Embodiment 2

[0061] Preparation of Catalyst Component B

[0062] 0.648 grams (2.05 mmol) of magnesium chloride / silica gel carrier obtained with the preparation method in Example 1, under nitrogen protection, was added in 30 milliliters of hexanes, under stirring, was heated to 70 ℃ and reacted for 0.5 hours, then added 0.18 milliliters of normal butanol, stirred for 0.5 hour, removed the supernatant, added 30 milliliters of hexane to the reaction flask, and added 0.98 milliliters of TiCl under stirring. 4 , heated to 70°C and stirred for 1 hour, lowered to room temperature, added 0.630 ml (8.04 mmol) of epichlorohydrin, raised to 50.0°C for 2 hours, then removed the supernatant, and washed the solid with hexane solvent for 3 times When the mother liquor in the upper layer was colorless, it was blown dry with nitrogen gas at 50° C. until it was in a fluid state to obtain a solid B catalyst component. After analysis, the Ti content was 3.78%wt.

Embodiment 3

[0064] Preparation of Catalyst Component C

[0065] 0.737 grams (2.33 mmol) of the magnesium chloride / silica gel carrier obtained by the preparation method in Example 1 was added to 30 milliliters of hexane under nitrogen protection, and heated to 70 ° C for 0.5 hours under stirring, then added 0.21 milliliters of normal butanol, stirred for 0.5 hours, removed the supernatant, added 30 ml of hexane to the reaction flask, and added 1.11 ml of TiCl 4 , heated to 70°C and stirred for 1 hour, lowered to room temperature, added 1.430 ml (18.2 mmol) of epichlorohydrin, raised to 50.0°C for 2 hours, then took off the supernatant, and washed the solid for 3 times with hexane solvent When the mother liquor in the upper layer was colorless, it was blown dry with nitrogen gas at 50°C until it was in a fluid state to obtain a solid C catalyst component. After analysis, the Ti content was 3.80%wt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com