Coating paper for printing

A technology for coating paper and pulp, applied in papermaking, papermaking machine, wet end of paper machine, etc., can solve the problem of reducing the number of microfibers, and achieve the effect of good texture, strong interlayer strength and excellent printability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

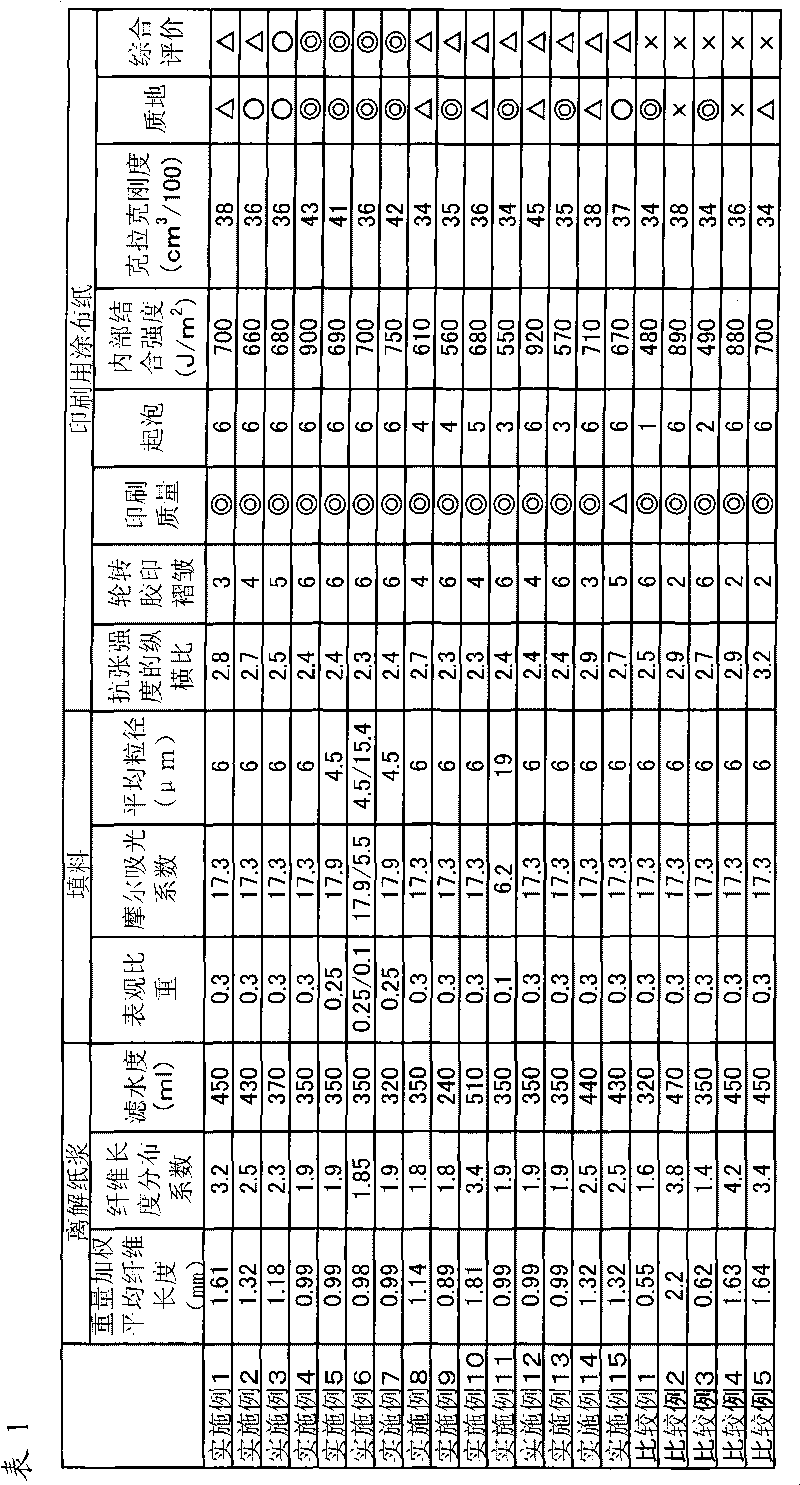

Examples

Embodiment 1

[0123] Production of hardwood pulp

[0124] Using a Lo-Solids cooking kettle (manufactured by Andritz Group), the broad-leaved tree chips formed by Acacia mangium: Eucalyptus grandis=30:70 (mass ratio) were subjected to kraft cooking by Lo-Solids cooking method. At this time, white liquor with a degree of sulfidation of 28 was used. Regarding the white liquor addition rate, 10% of active alkali was added to the chips supply system relative to the absolute dry mass of chips, and 8% was added to the cooking zone, and 2% was added to the In the washing area, cooking is carried out at a cooking temperature of 146°C. After the steamed flakes are disentangled, they are washed, screened, and washed again to obtain unexposed pulp.

[0125] In the aforementioned unexposed pulp, 1.7% caustic soda and 1.8% oxygen were added per dry pulp mass, and two-stage oxygen-alkali bleaching was carried out at a pulp concentration of 10%, 98°C, and 50 minutes. At this time, caustic soda is added...

Embodiment 2

[0144] Production of hardwood pulp

[0145] As a beating treatment condition, in addition to making the pulp concentration 4.3%, it is introduced into a double-action disc refiner connected in parallel with 3 machines (knife material: SUS, knife width: 1.0mm, groove width: 2.0mm 1 machine and knife material : 17 chromium, blade width: 2.4mm, groove width: 2.4mm (2 machines used in combination), beat to CSF450ml, and obtain hardwood pulp in the same manner as in Example 1.

[0146] Production of conifer pulp

[0147] In Example 1, except that the softwood bleached pulp (concentration: 4.4% by mass) was introduced into a 1-unit double-action disc refiner (knife material: 17 chrome, knife width: 4.8mm, groove width: 4.8mm), Beat until CSF was 480 ml, and obtain conifer beating pulp in the same manner as in Example 1.

[0148] Production of base paper

[0149] In the pulp slurry mixed with coniferous trees: broad-leaved trees=10:90 (mass ratio) by the aforementioned beati...

Embodiment 3

[0153] Production of hardwood pulp

[0154] As a beating treatment condition, in addition to making the pulp concentration 4.4%, it is introduced into a double-action disc refiner connected in parallel with 3 machines (knife material: SUS, knife width: 1.0mm, groove width: 2.0mm 1 machine and knife material : 17 chromium, blade width: 2.4mm, groove width: 2.4mm (2 machines used in combination), beat to CSF400ml, and obtain hardwood pulp in the same manner as in Example 1.

[0155] Production of conifer pulp

[0156] As the beating treatment conditions, in addition to making the pulp concentration 4.4%, introducing it into a 1-machine double-action disc refiner (knife material: 17 chrome, knife width: 4.8mm, groove width: 4.8mm), and beating to CSF480ml, Conifer beating pulp was obtained in the same manner as in Example 1.

[0157] Production of base paper

[0158] In the pulp slurry mixed with coniferous trees: broad-leaved trees=5:95 (mass ratio) by the aforementioned ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com