Method for preparing multi-wall carbon nanotubes

A technology of multi-walled carbon nanotubes and active components, applied in the direction of multi-walled carbon nanotubes, carbon nanotubes, nanocarbons, etc., can solve the problems of inability to obtain high specific surface area and high-purity multi-walled carbon nanotubes, Achieve the effect of low cost, good effect and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

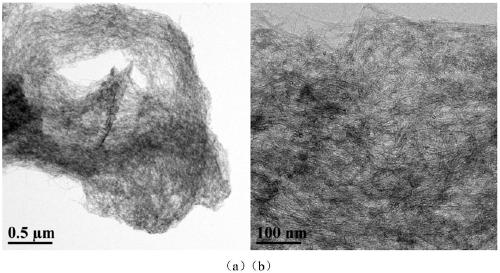

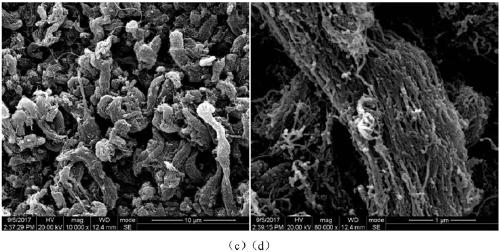

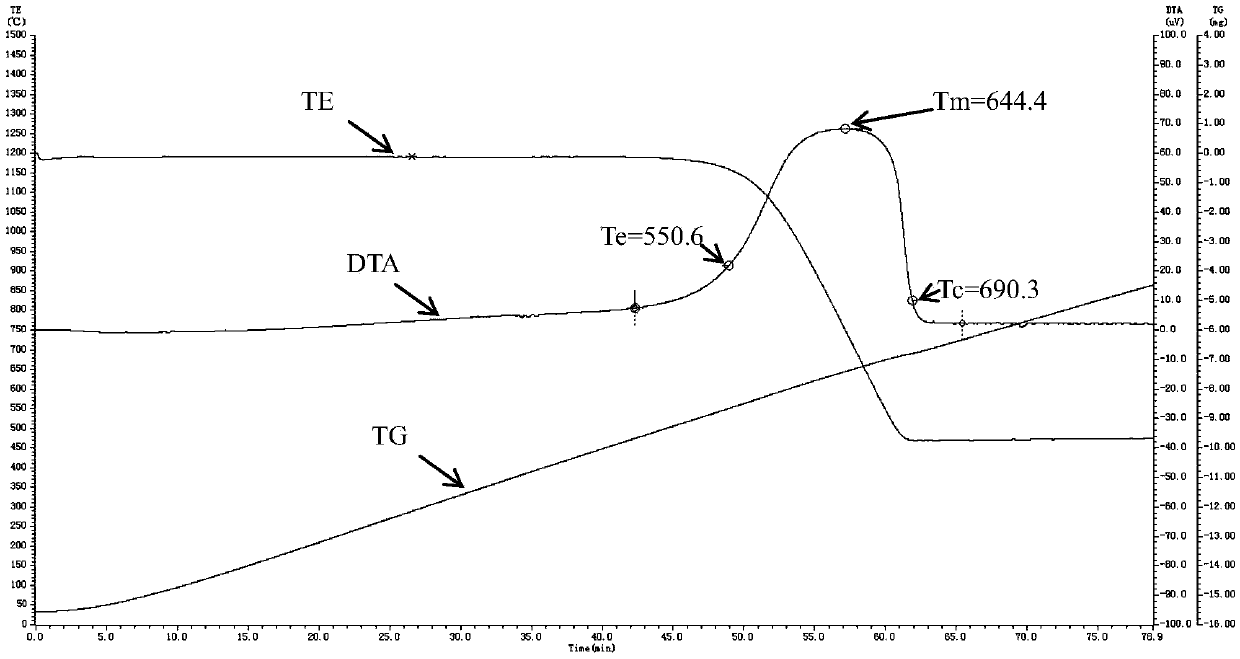

Embodiment 1

[0056] Use Fe, Co, Al and Mg nitrates and urea to prepare 0.3mol / L mixed salt solution and 10mol / L alkaline solution, wherein the atomic ratio of Fe and Co is 10:1, and the atomic ratio of Mg and Al Ratio is at 2, and the consumption of urea is 15 times (mol ratio) of metal ion, and the content of active component is 15% of catalyst gross weight, and above-mentioned two kinds of solutions are mixed at room temperature, under stirring state, with 3 ℃ / The temperature was slowly raised to 103° C. at a rate of 1 min, and the stirring was continued for 12 h, and then the reaction was stopped. The resulting suspension was placed in an oven at 95° C. for 12 h, then cooled and filtered, washed three times with deionized water, and freeze-dried. The catalyst was loaded into a fixed-bed reactor, and first reduced with nitrogen containing 30% hydrogen at 800°C for 10 min. Then the gas was switched to 100% methane and reacted at 800 °C for 1 h. Switch the gas to nitrogen, and cool down...

Embodiment 2

[0058] Use Fe, Ni, Al and Mg sulfate and urea to prepare 0.2mol / L mixed salt solution and 10mol / L alkaline solution, wherein the atomic ratio of Fe and Ni is 12:1, and the atomic ratio of Mg and Al Ratio is at 3, and the consumption of urea is 18 times (molar ratio) of metal ion, and the content of active component is 12% of catalyst gross weight, and above-mentioned two kinds of solutions are mixed at room temperature, under agitation, with 3 ℃ / Slowly raise the temperature to 100°C at a rate of min, continue to keep stirring for 12 hours, and then stop the reaction. The resulting suspension was placed in an oven at 95° C. for 12 h, then cooled and filtered, washed three times with deionized water, and freeze-dried. The catalyst was loaded into a fixed-bed reactor, and first reduced with nitrogen containing 30% hydrogen at 760°C for 10 min. Then the gas was switched to 100% natural gas, and the reaction was carried out at 760° C. for 1 h. Switch the gas to nitrogen, and coo...

Embodiment 3

[0060] Use Fe, Co, Al and Mg nitrate and ammonium molybdate to make 0.15mol / L mixed salt solution, use ammonium bicarbonate and ammonium carbonate to make 2mol / L alkaline precipitant solution, in which Fe, Co The atomic ratio of Mo and Mo is 10:1:0.5, the atomic ratio of Mg and Al is 2, the consumption of ammonium bicarbonate and ammonium carbonate is 2 times (molar ratio) of metal ion, and the content of active component is 1% of the total weight of catalyst 15%, add the mixed salt solution dropwise to the stirring alkaline precipitant solution. After the dropwise addition, slowly raise the temperature to 80°C at a rate of 3°C / min, continue to keep warm and stir for 2h, and then stop the reaction. The suspension was left to stand in an oven at 90° C. for 12 h, then cooled and filtered, washed three times with deionized water, and freeze-dried. The catalyst was loaded into a fixed-bed reactor, and first reduced with nitrogen containing 20% hydrogen at 780° C. for 5 minutes. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com