Anti-vibration tool rest with adjustable cutter bar extended length for deep hole turning

A deep-hole turning and tool holder technology, applied in the direction of tool holder, etc., can solve the problems of cutting chatter, tool change, efficiency tool setting error, and the inability to automatically adjust the overhang length of the tool holder, so as to improve processing efficiency and ensure consistency. , to facilitate the effect of cutting chatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

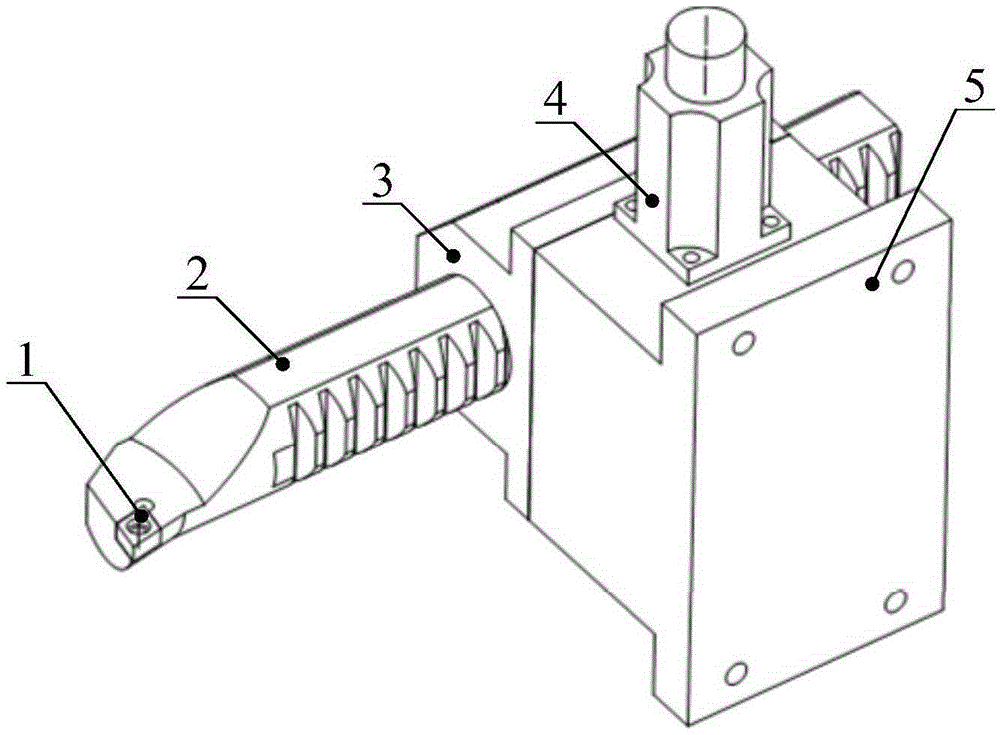

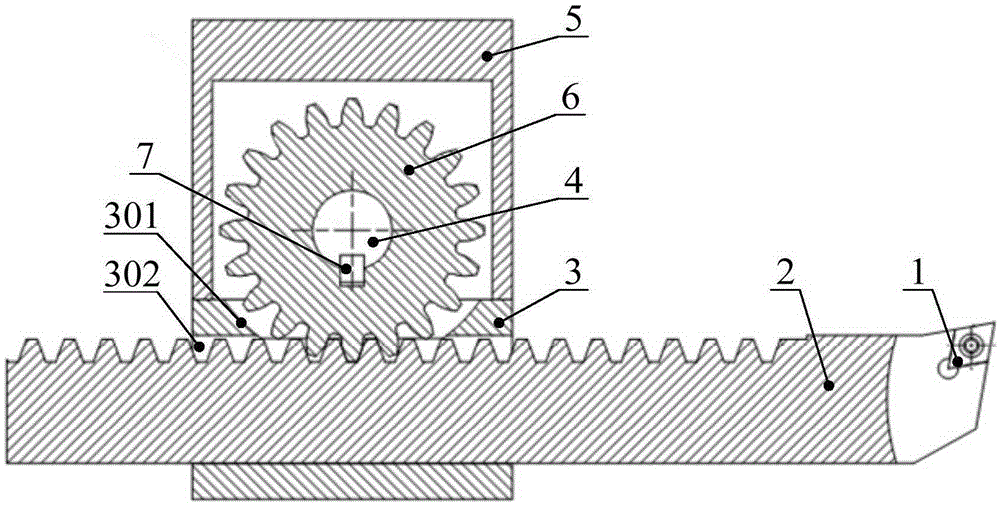

[0024] An anti-vibration tool holder with adjustable length of tool bar for deep hole turning of the present invention comprises a combined blade 1, a tool bar, a tool bar support 3 and a power drive unit; end, the other end of the knife rod passes through the knife rod groove 302 of the knife rod support 3, and the said knife rod realizes expansion and contraction in the length direction through the power drive unit.

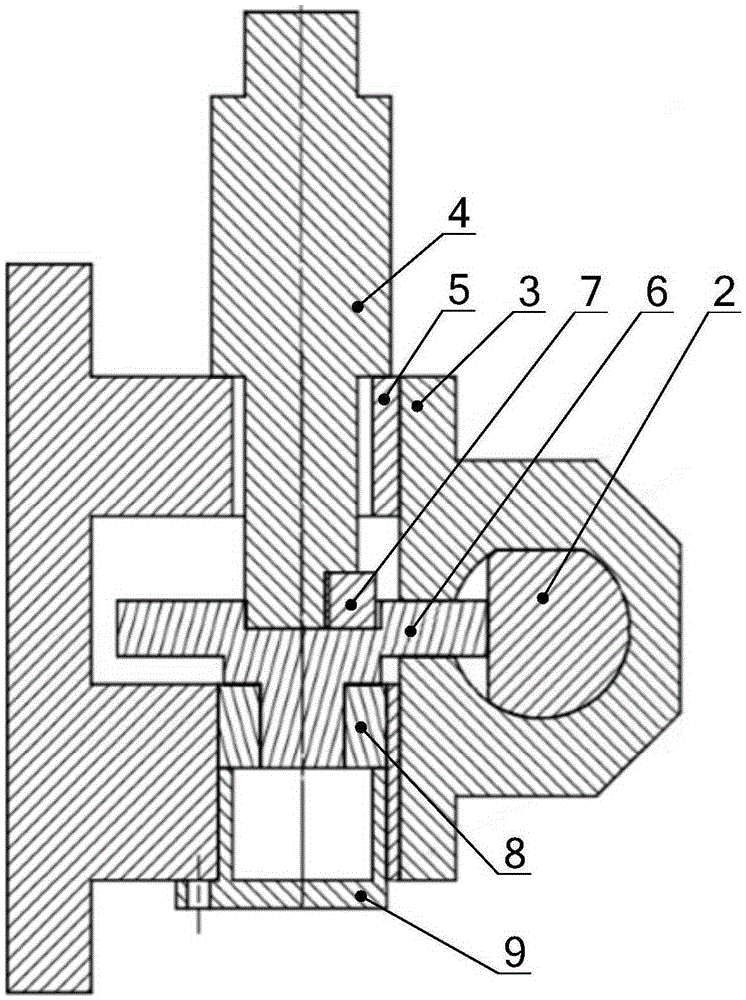

[0025] See attached figure 1 , attached figure 2 And attached image 3 , the cutter bar is a rack-type cutter bar 2, and the power drive unit includes a stepper motor 4, a motor base 5 and a drive gear 6; the motor base 5 is connected to the cutter bar support 3, and the The driving gear 6 is arranged inside the motor base 5, the driving gear 6 is engaged with the rack on the rack type knife bar 2, the stepping motor 4 is fixed on the motor base 5, the The output shaft of the stepping motor 4 is fixedly connected with the drive gear 6 .

[0026] The output...

Embodiment 2

[0032] The difference between this embodiment and the first embodiment is that the adjustment of the suspension length of the tool rod of the anti-vibration tool post is realized in the form of a screw guide.

Embodiment 3

[0034] See attached Figure 7 , The difference between this embodiment and Embodiment 1 is that the adjustment of the suspension length of the tool bar of the anti-vibration tool post is realized in the form of a differential hydraulic cylinder 13 .

[0035] The cutter rod is a hydraulic rod type cutter rod 11, and both the hydraulic rod type cutter rod 11 and the differential hydraulic cylinder 13 are installed on the hydraulic cylinder base 12 fixed on the servo tool holder of the machine tool, and the differential pressure is controlled by the servo valve. Type hydraulic cylinder 13 drives hydraulic rod type knife bar 11 telescopic, can realize the adjustment of knife bar suspension length equally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com