High-precision constant-transmission-ratio transmission mechanism based on ball screws

A technology of ball screw and fixed transmission ratio, which is applied in the field of precision transmission, can solve the problems of lack of position stability, looseness of flexible transmission, and low dynamic stiffness of flexible transmission, and achieve long-term position stability, high dynamic stiffness, The effect of high transmission precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

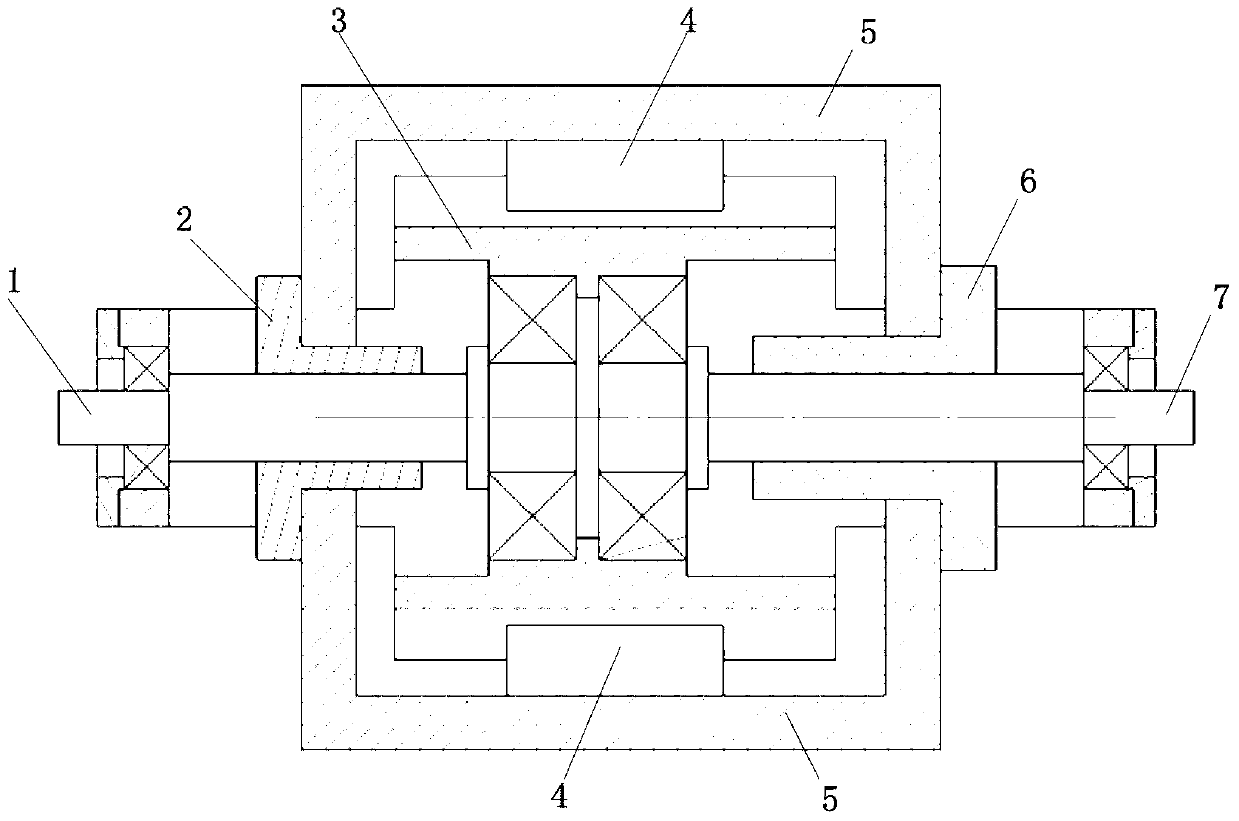

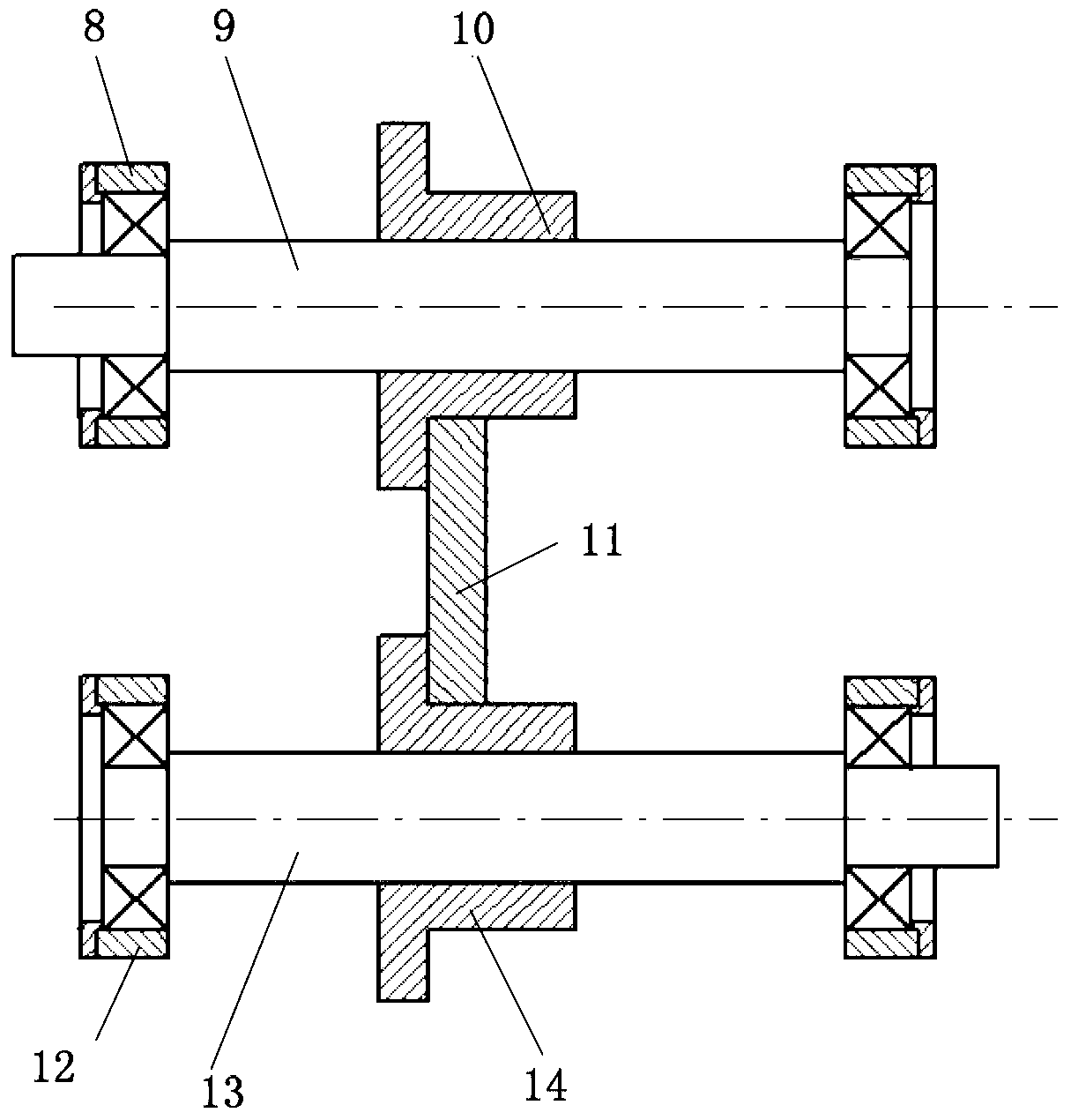

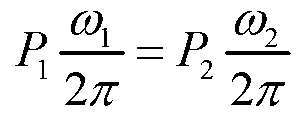

[0016] The inventive idea of the present invention is to select a suitable ball screw and its length according to the space of the used occasion and the range of rotation angle of the transmission, and to select the leads and precision grades of the two screw screws according to the required transmission ratio and transmission accuracy. The screw shaft is installed on the fixed seat through two angular contact ball bearings. During assembly, the bearing end cover is repaired to eliminate the axial gap, so as to improve the overall rigidity of the transmission mechanism. One lead screw shaft is connected with the input end, and the other lead screw is connected with the output end, so that a constant transmission ratio transmission from the input end to the output end can be realized. The rotation direction of the two screw rods can be flexibly selected to realize transmission in different rotation directions.

[0017] The present invention will be described in detail below i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com