Compound control method and system for hydraulic drive unit position control system

A technology of drive unit and control system, which is applied in the directions of fluid pressure actuation system components, fluid pressure actuation devices, program control manipulators, etc., can solve the lack of engineering practicability, the lack of pertinence of dynamic stiffness control compensation, and the complex control method. and other problems, to achieve the effect of simple algorithm, improved robustness, improved accuracy and robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

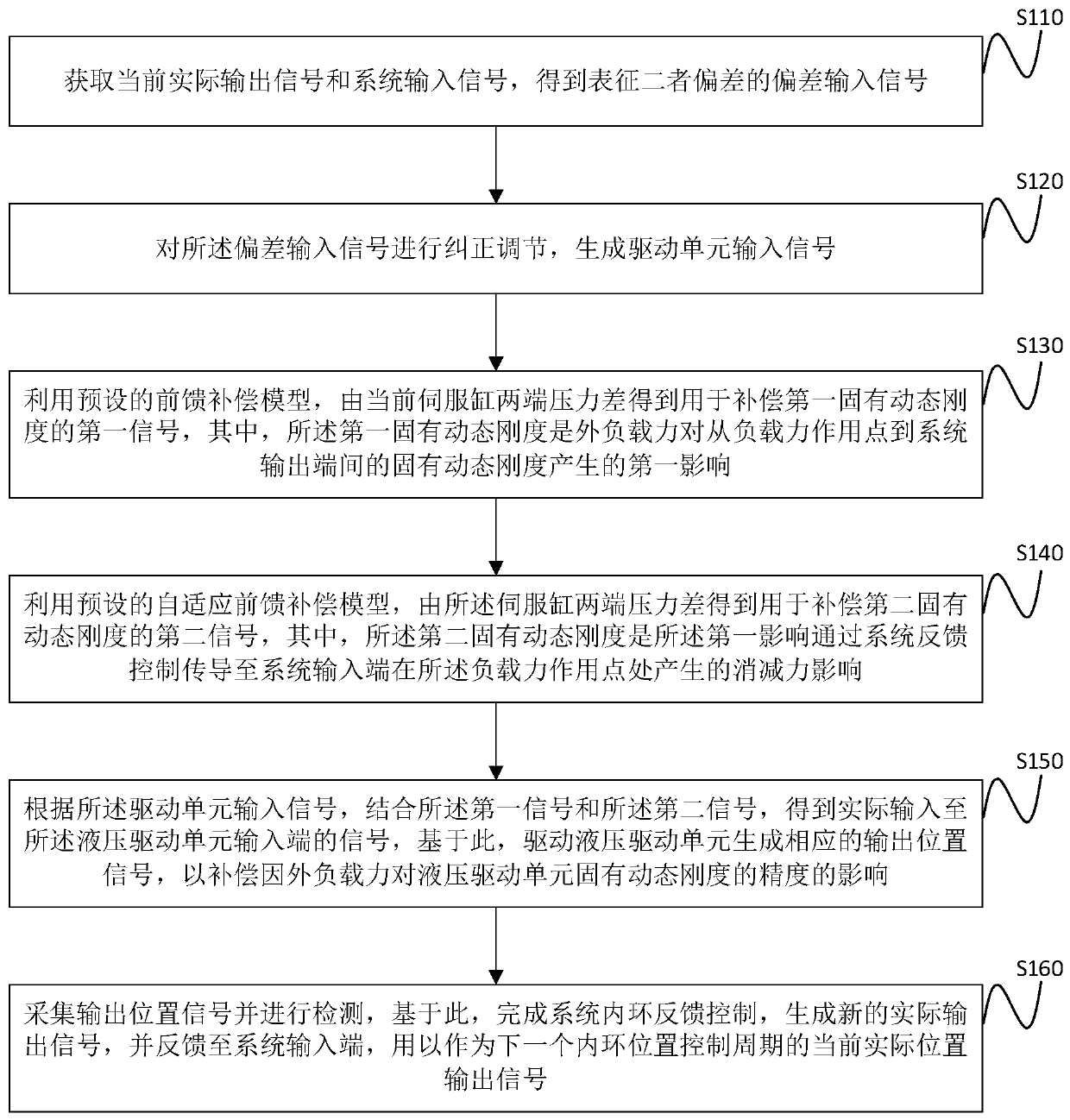

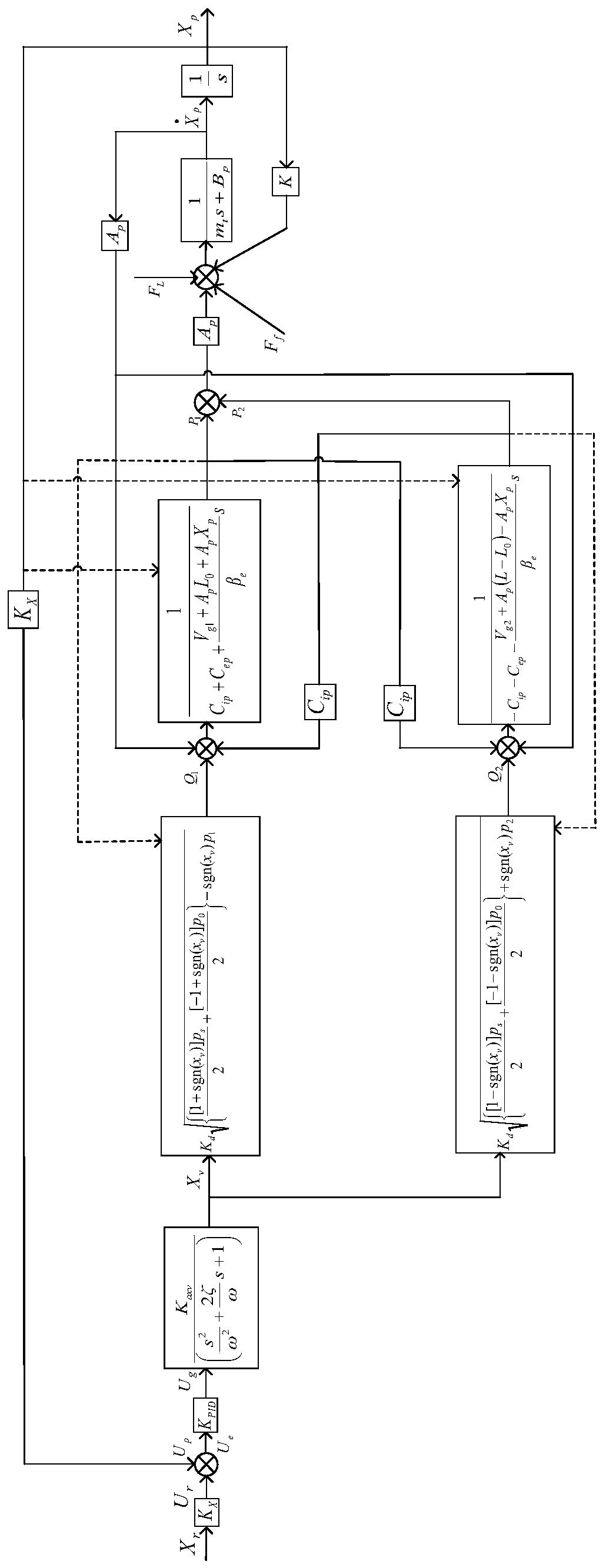

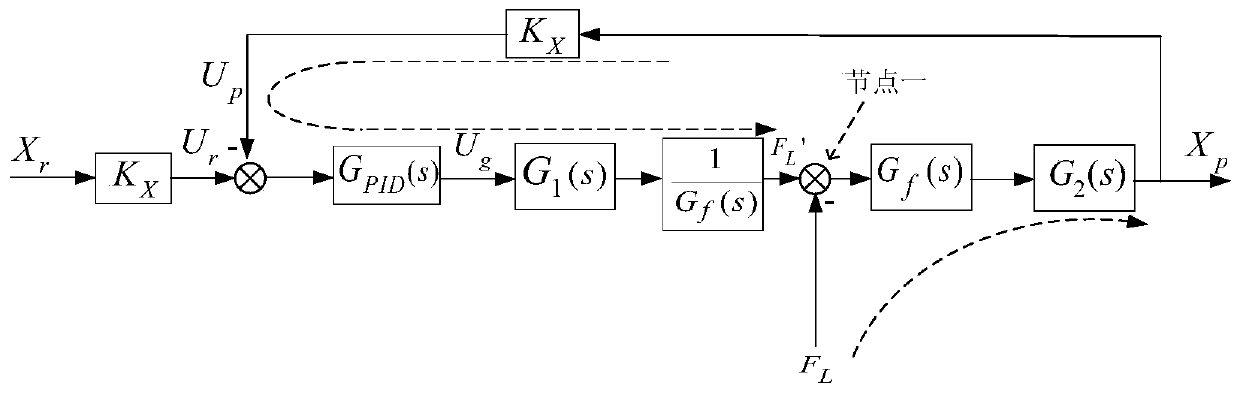

[0046] figure 2 It is a block diagram of the transfer function model of the existing hydraulic drive unit position control system for the composite control method of the hydraulic drive unit position control system according to the embodiment of the present application. The existing hydraulic drive unit (inner ring) position control system includes: system input module 1, position controller 2, hydraulic drive unit 3, and feedback control module 4, figure 2 The transfer functions of the various components of the existing position control system are shown. Among them, the system input module 1 is used to obtain the given voltage input signal (system input signal) of the position control system and the voltage signal (actual output signal) corresponding to the current system output position signal detected by the displacement sensor 11, and obtain the deviation. The position controller 2 obtains the above-mentioned deviation input signal from the system input module 1, and p...

Embodiment 2

[0093] In the actual application process, due to the simplification and neglect steps in the construction process of the feedforward compensation model and the adaptive feedforward compensation model, only the feedforward compensation control and the adaptive feedforward compensation control can make the hydraulic drive unit receive The stiffness after the external load force is improved, but it may not be possible to fully make the hydraulic drive unit stiffness reach the infinite target state.

[0094] Therefore, in order to further improve the effect of the feedforward compensation control and the adaptive feedforward compensation control in the first embodiment above, a self-tuning position control is designed on the basis of the feedforward compensation control and the adaptive feedforward compensation control method, this method is used to control the forward channel gain of the online control system, and further increase the inherent dynamic stiffness of the position con...

Embodiment 3

[0106] In addition, based on the composite control method in Embodiment 1 of the present invention, the present invention also proposes a composite control system for the position control system of the hydraulic drive unit, which is used to realize the above-mentioned composite control method. Figure 10 It is a structural schematic diagram of a compound control system used for a position control system of a hydraulic drive unit according to an embodiment of the present application. Such as Figure 10 As shown, the above compound control system includes: a system input module 1 , a position controller 2 , a hydraulic drive unit 3 , a feedforward compensation controller 5 , an adaptive feedforward compensation controller 6 and a feedback control module 4 .

[0107] Among them, the system input module 1, which is implemented according to the above step S110, is configured as the current actual output signal and the system input signal, and obtains a deviation input signal repres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com