Double-stator axial magnetic flow arc-shaped permanent magnet motor

A permanent magnet motor, axial magnetic flux technology, applied in the direction of magnetic circuit shape/style/structure, electrical components, electromechanical devices, etc., can solve the problems of system vibration, poor dynamic stiffness, slow motion response, etc., and achieve high dynamic stiffness. , the effect of reducing the volume and weight, and improving the response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

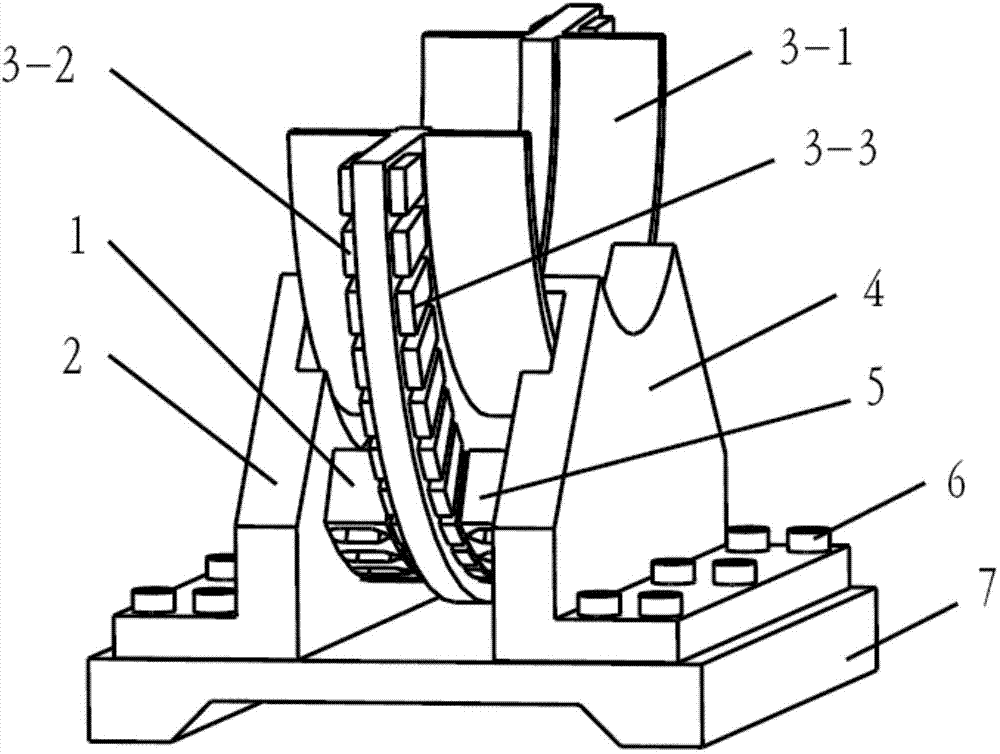

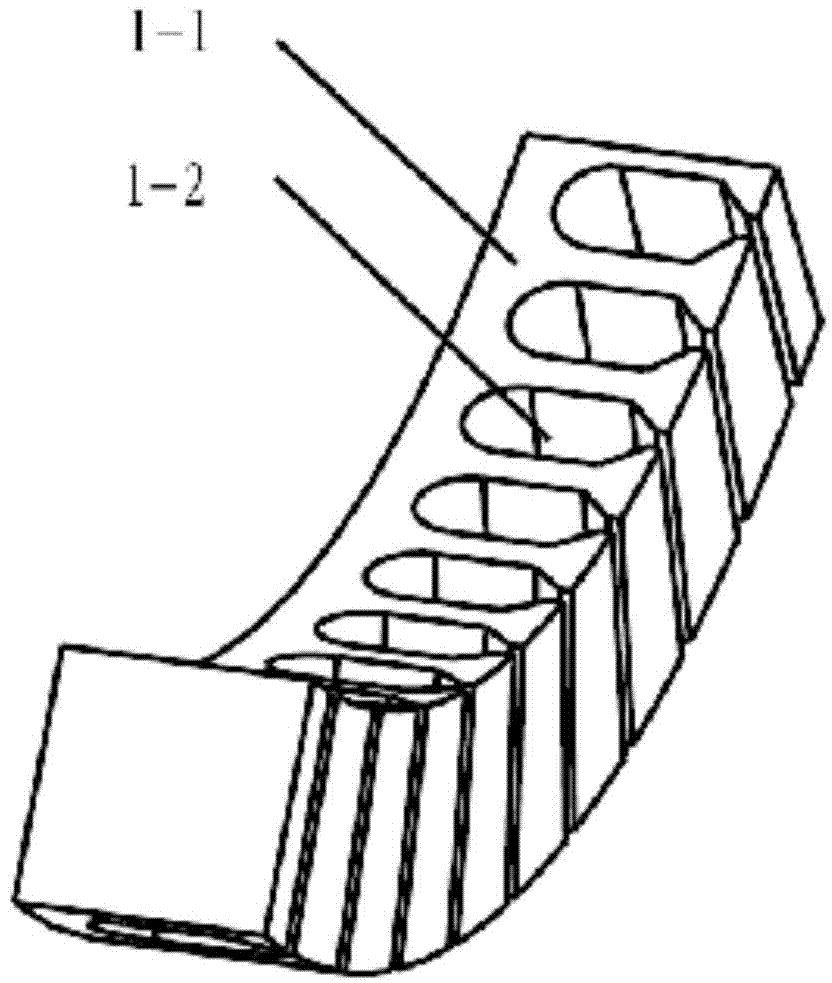

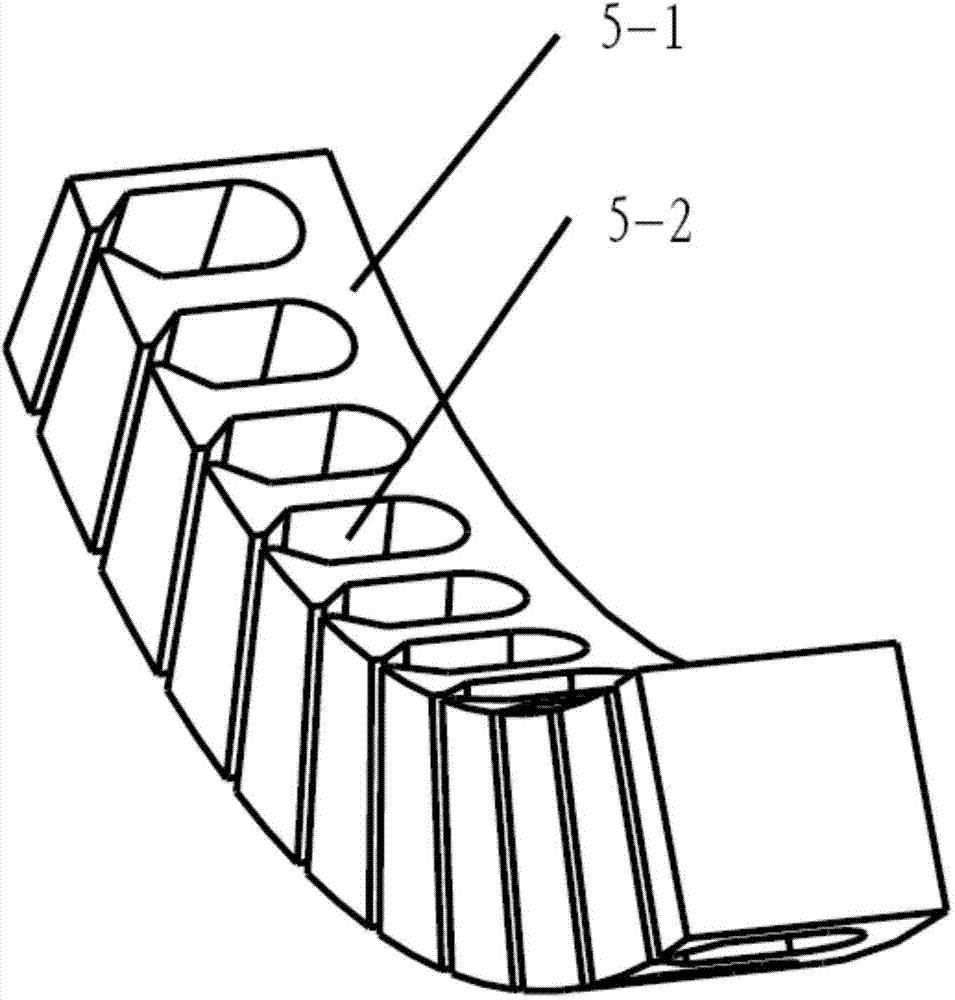

[0018] Specific implementation mode one: combine Figure 1 to Figure 8 Describe this embodiment. This embodiment includes a left side arc stator 1, a left support bracket 2, an arc rotor core 3-1, a left permanent magnet 3-2, a right permanent magnet 3-3, and a right support Bracket 4, right side arc-shaped stator 5, fastening screw 6 and base 7; the section of the arc-shaped rotor core 3-1 is T-shaped, and the arc-shaped rotor core 3-1 includes a supporting part 3-1 -1 and effective working part 3-1-2; arc rotor iron core 3-1, left permanent magnet 3-2 and right permanent magnet 3-3 form arc rotor, wherein the left permanent magnet 3-2 The N and S poles are alternately arranged on the left side of the arc-shaped rotor core 3-1, and the N and S poles of the right permanent magnet 3-3 are alternately arranged on the right side of the arc-shaped rotor iron core 3-1; the left side of the arc-shaped stator 1 Located on the left side of the rotor, the right arc-shaped stator 5 is ...

specific Embodiment approach 2

[0019] Specific implementation mode two: combination figure 1 , figure 2 , image 3 , Figure 4 , Image 6 , Figure 7 , Figure 8 with Figure 9 This embodiment is different from Embodiment 1 in that the permanent magnets are arranged as a series magnetic circuit, and the polarities of the permanent magnets are different at the opposite sides of the arc-shaped rotor core. When the N pole on the left side faces the arc-shaped rotor core 3-1, the right side is the S pole facing the arc-shaped rotor core 3-1, and when the left side is the S pole facing the arc-shaped rotor core 3-1, the right side is the N pole facing the arc-shaped rotor core 3-1, and the two sides The N and S poles are arranged alternately.

Embodiment approach 3

[0020] Embodiment 3: The difference from Embodiment 1 or Embodiment 2 is that the arc of the arc-shaped rotor is larger than that of the stator, and the arc length of the arc-shaped rotor can be designed according to the requirements of the operating angle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com