Method for preparing high-smoothness poly-m-phenyleneisophthalamide paper for insulation

A kind of aramid paper, smoothing technology, applied in papermaking, papermaking machine, paper post-processing and other directions, can solve the problems of high running cost, weak effect, high energy consumption, etc. The effect of tear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

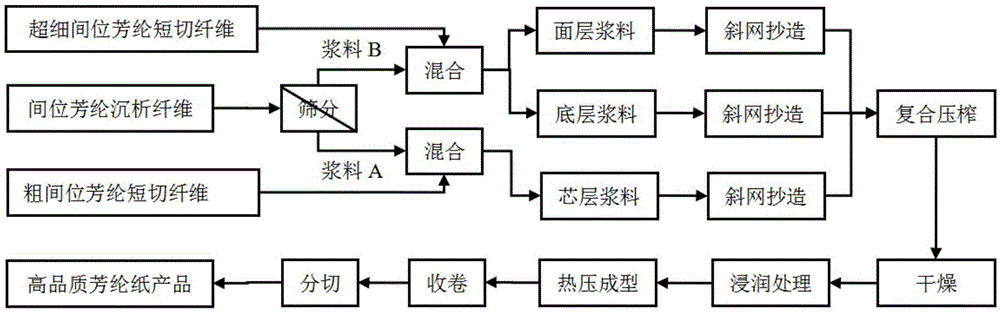

Method used

Image

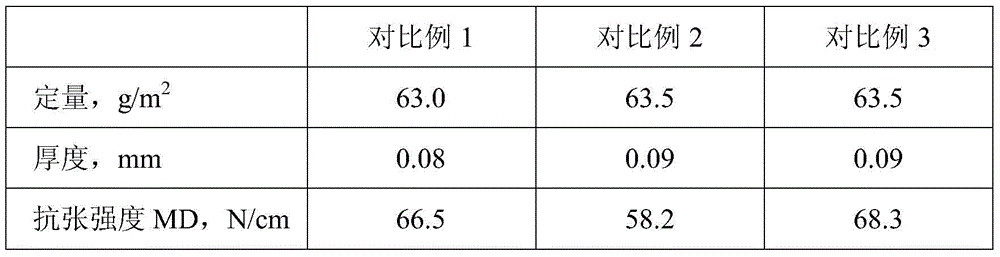

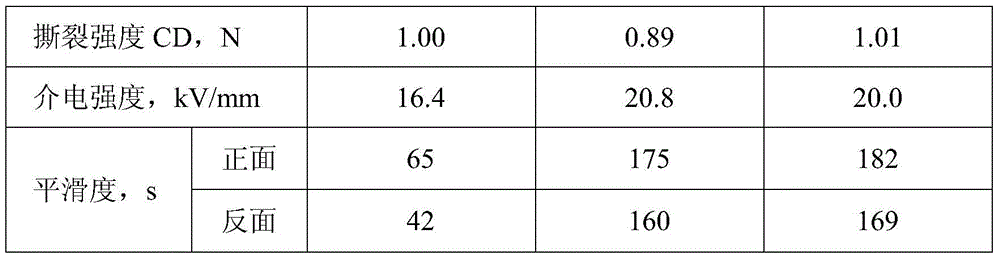

Examples

Embodiment 1

[0038] (1) The meta-aramid fibrids are fully decomposed in water, and the fiber length distribution ≥ 100 mesh pulp A and the fiber length distribution < 100 mesh pulp B are screened out. The mass concentrations of pulp A and pulp B are both 1% g / mL;

[0039](2) The absolute dry mass of the meta-aramid fibrids is 50% of the slurry A relative to the total dry mass percentage of the core fiber, and the coarse meta-aramid is 50% relative to the total dry mass percentage of the core fiber. Aramid chopped fibers are fully mixed and dispersed. The length of coarse meta-aramid chopped fibers is 12mm and the fineness is 2D. The core layer is formed by ultra-low concentration inclined wire forming; the concentration of ultra-low concentration inclined wire forming is 0.05%;

[0040] (3) The absolute dry mass of the meta-aramid fibrids is 80% of the slurry B relative to the total absolute dry mass of the surface layer fibers, and the ultra-fine meta-position is 20% of the relative surfa...

Embodiment 2

[0045] (1) The meta-aramid fibrids are fully decomposed in water, and the fiber length distribution ≥ 100 mesh pulp A and the fiber length distribution < 100 mesh pulp B are screened out. The mass concentrations of pulp A and pulp B are both 3% g / mL;

[0046] (2) The absolute dry mass of the meta-aramid fibrids is 60% of the slurry A relative to the total dry mass percentage of the core fiber, and the coarse meta-aramid is 40% relative to the total dry mass percentage of the core fiber. The aramid chopped fiber is fully mixed and dispersed, the length of the coarse meta-aramid chopped fiber is 8mm, and the fineness is 3D. The core layer is formed by ultra-low concentration inclined wire forming; the concentration of ultra-low concentration inclined wire forming is 0.01%;

[0047] (3) The absolute dry mass of the meta-aramid fibrids is 70% of the slurry B relative to the total absolute dry mass percentage of the surface layer fibers, and the ultrafine meta-position is 30% of th...

Embodiment 3

[0052] (1) The meta-aramid fibrids are fully decomposed in water, and the fiber length distribution ≥ 100 mesh pulp A and the fiber length distribution < 100 mesh pulp B are screened out. The mass concentrations of pulp A and pulp B are both 5% g / mL;

[0053] (2) The absolute dry mass of the meta-aramid fibrids is 40% of the slurry A relative to the total dry mass percentage of the core fiber, and the coarse meta-aramid is 60% relative to the total dry mass percentage of the core fiber. The aramid chopped fiber is fully mixed and dispersed, the length of the coarse meta-aramid chopped fiber is 6mm, and the denier is 4D, and the core layer is formed by ultra-low concentration inclined wire forming; the ultra-low concentration inclined wire forming papermaking concentration is 0.1%;

[0054] (3) The absolute dry mass of the meta-aramid fibrids is 60% of the slurry B relative to the total absolute dry mass percentage of the surface layer fibers, and the ultra-fine meta-position i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com