Technological process and apparatus for delinting of cotton seeds

A process method, cottonseed technology, applied in the directions of separating plant fibers from seeds, treating seeds and rhizomes, and producing bast fibers by chemical methods, which can solve the problems of cotton linters that cannot be recycled, poor fluidity of cottonseeds, and waste Unfavorable environmental protection and other issues, to achieve the effect of increasing mechanical operating costs, good fluidity, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0023] a. The cottonseed with 6-7mm short staples is delinted with a mechanical delinting device. After mechanical delinting, the length of the short staples on the cottonseed is 3-4mm, and only remains at the two ends of the vertical cottonseed ,

[0024] b. Quantitatively spray foam dilute sulfuric acid on cottonseeds with 3-4mm short fibers, and mix well. velvet

[0025] c. Send the cottonseed sprayed with foam dilute sulfuric acid into the drying room for drying,

[0026] d. the dried cottonseed is polished, and the described polishing process is carried out in another above-mentioned mechanical delint device,

[0027] e. Clean the polished cottonseed, and the cleaning is carried out by winnowing or screening.

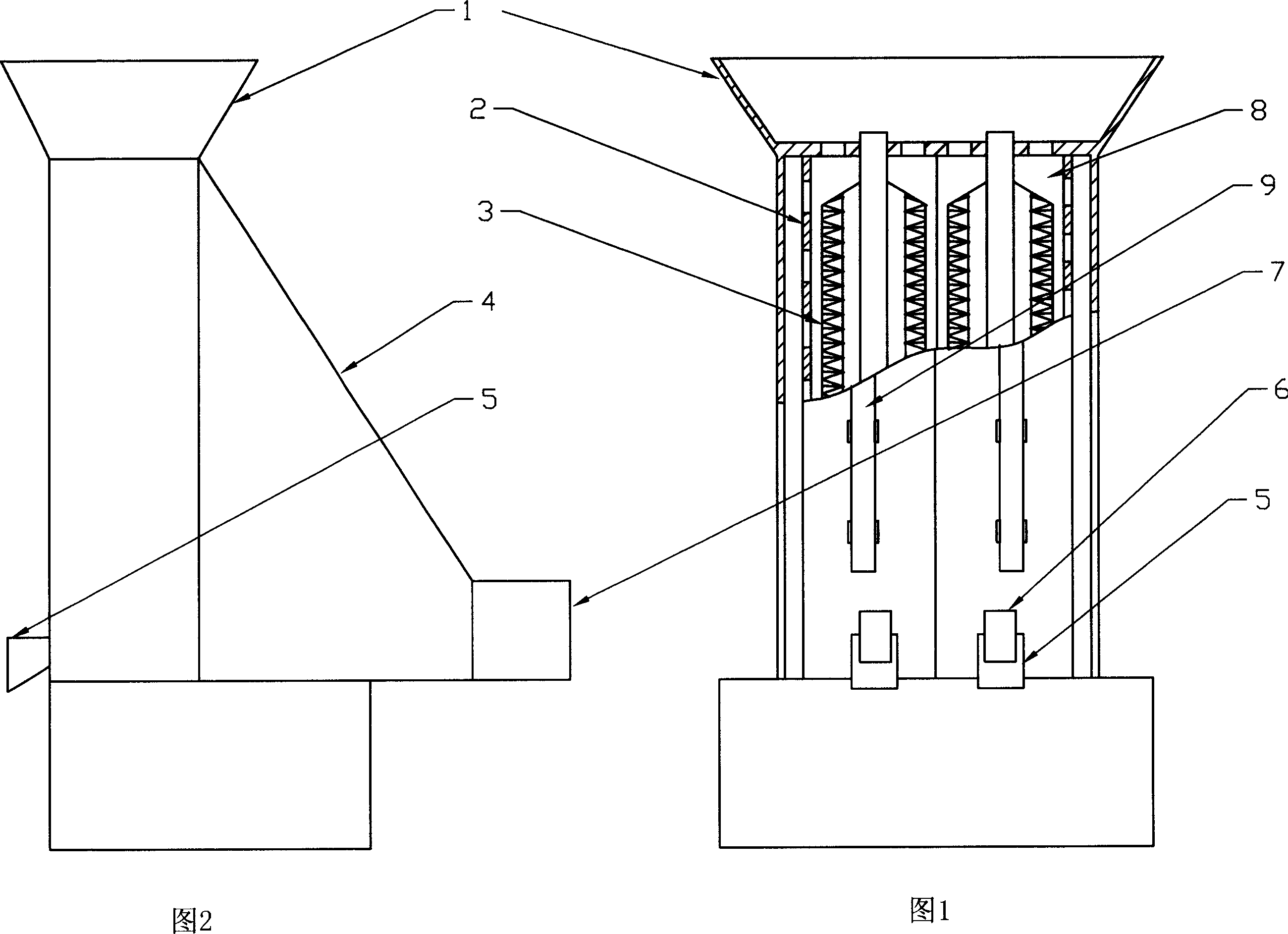

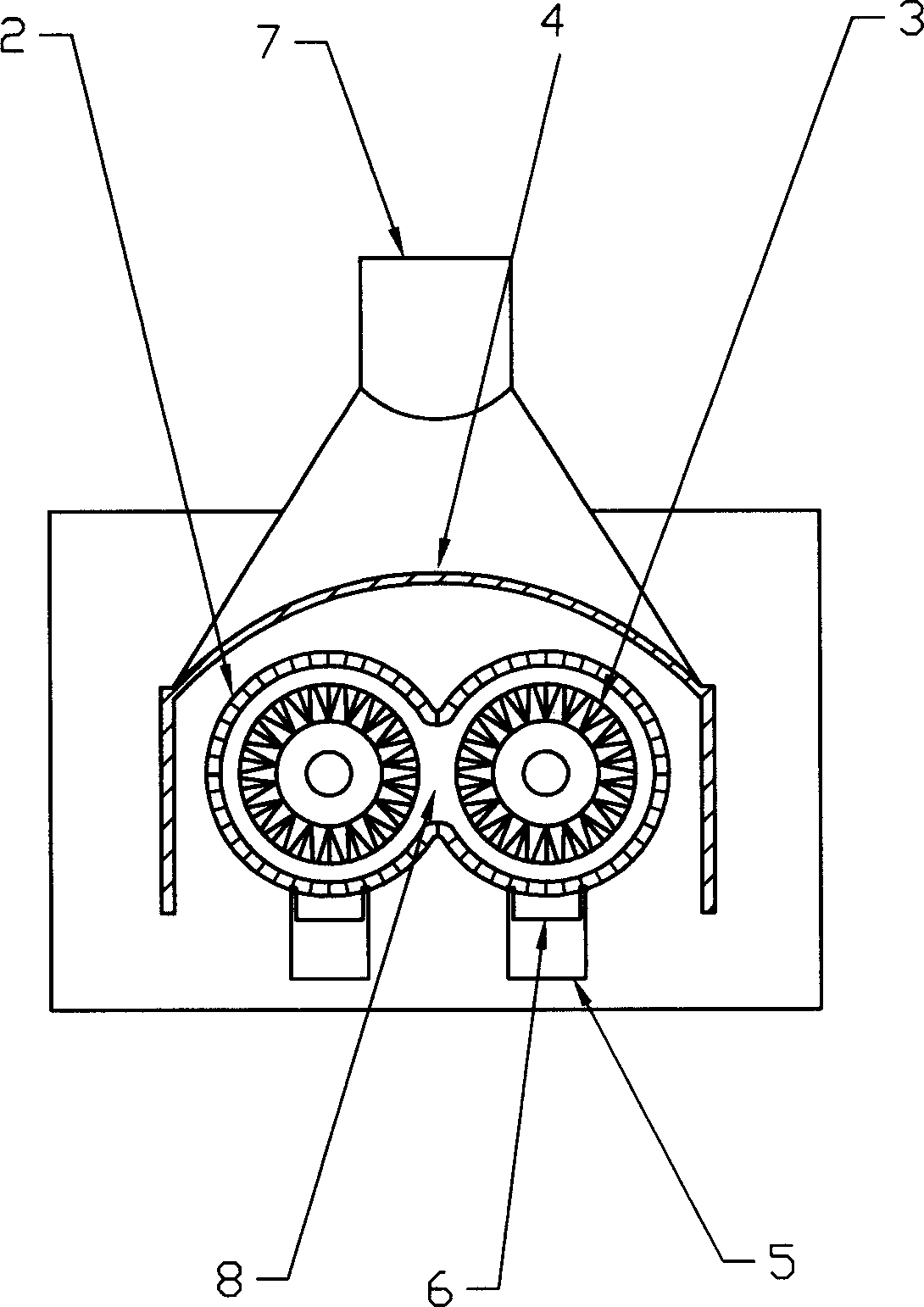

[0028] With reference to Fig. 1, Fig. 2 and Fig. image 3 , which includes a steel wire brush roll 3, a sieve plate 2, and a fleece cover 4, and is characterized in that: the steel wire brush roll 3 is vertically arranged, and the cottonseed falls freely under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com