Mudar floss silver used for spinning, processing method and equipment thereof

A technology of horn melon fiber and processing equipment, which is applied in the textile field, can solve the problems of difficult removal of seeds, difficult spinning, and difficult distortion, and achieve the effects of improving the ecological environment, convenient planting, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

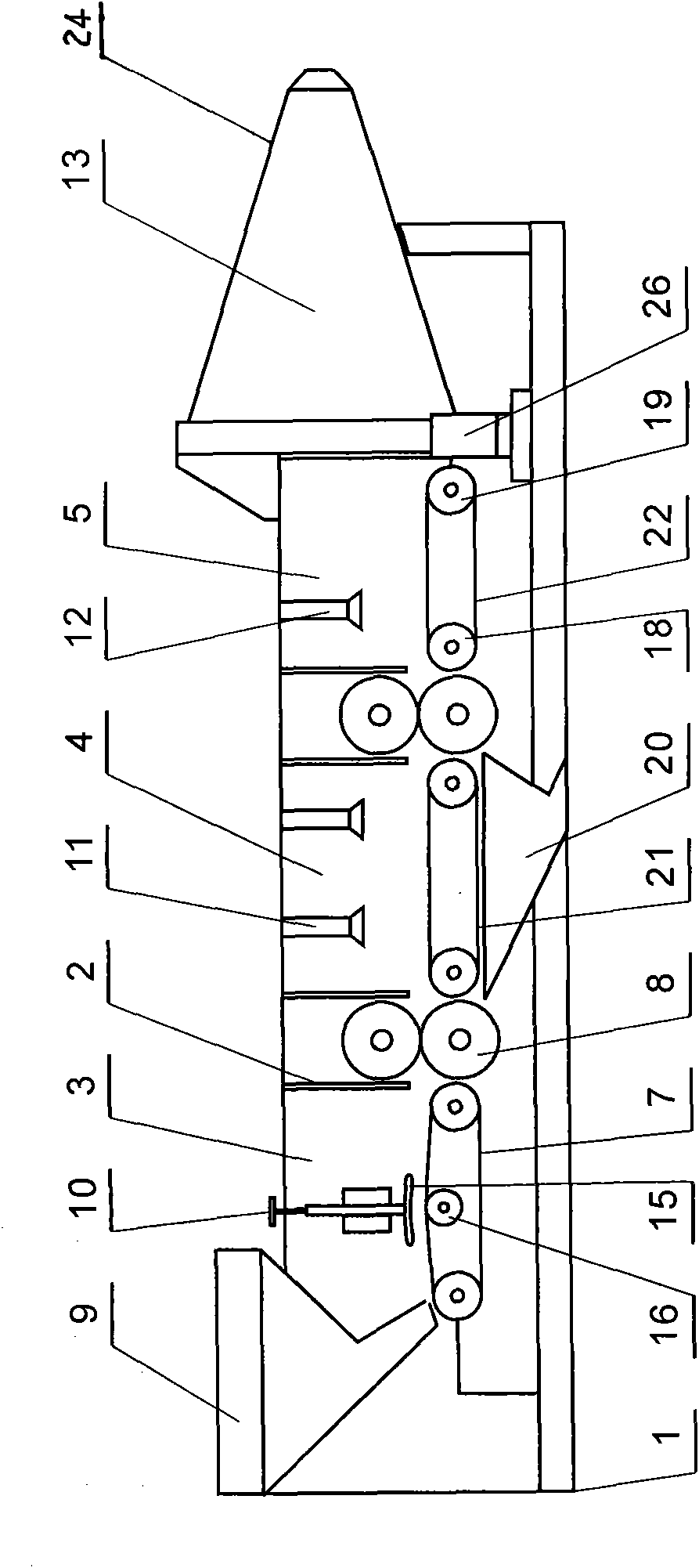

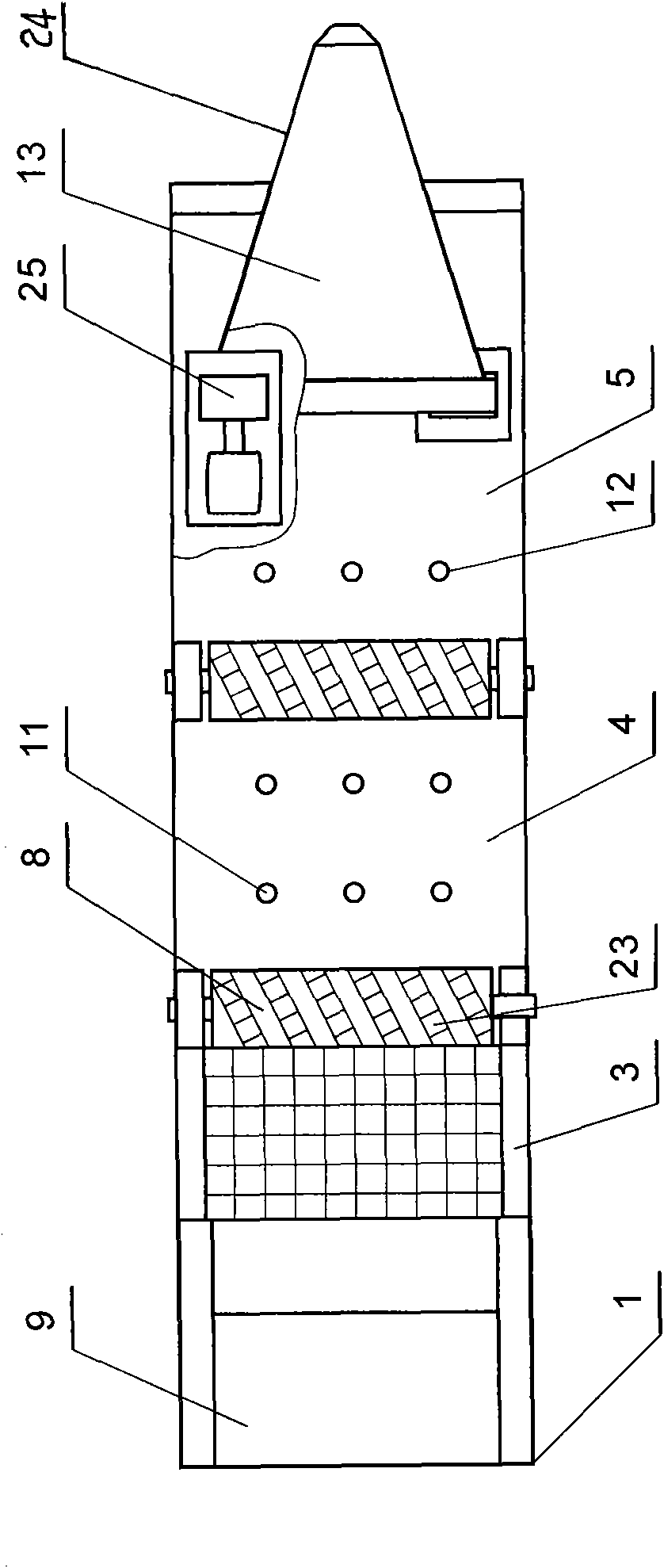

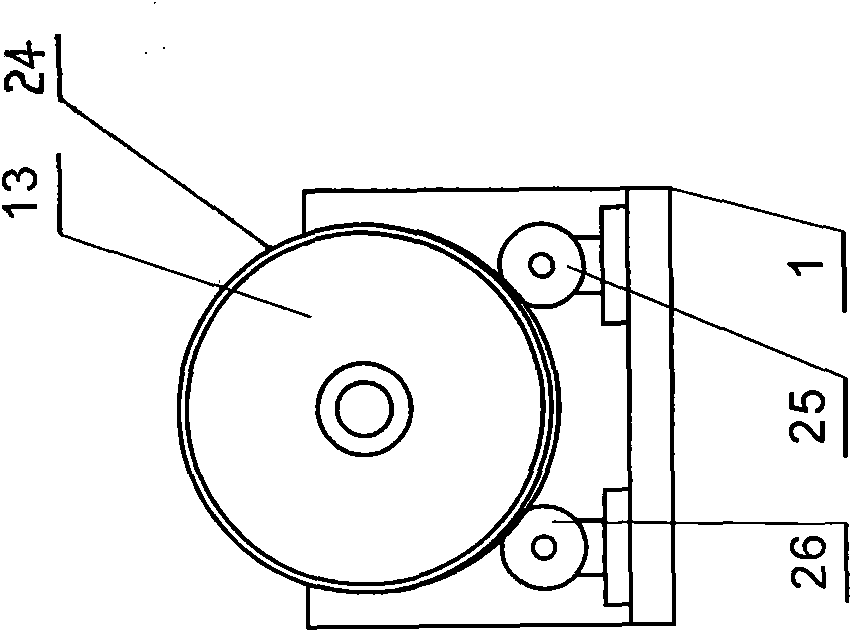

[0031] See attached Figure 5 , using mature croissanthus fruit, taking the pappus fiber with seeds at one end, that is, the croissant fiber is processed into cotton slivers for spinning through deseeding and tanning, which specifically includes the following steps:

[0032] a. Deseeding and cashmere extraction

[0033] Get the croissant melon fiber 17 that is seeded at one end in the mature and cracked croissant melon fruit, put it into the feed hopper 9 of the sliver processing equipment of the present invention, enter the wadding chamber 3 by the flat mesh conveyor belt 7, pass through the thickness limiter Hand wheel on 10 adjusts the gap between the limit plate 15 and the limit wheel 16, so that the horn melon fiber 17 is controlled at 1 to 2mm through the wadding thickness limiter 10 on the metal flat mesh conveyor belt 7, so that It becomes a thin floc, laid flat on the flat mesh conveyor belt 7 and sent to the first pair of rollers 8 for rolling, and the horn melon fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com