V-type cotton gin

A cotton gin and frame technology, applied in the direction of separating plant fibers from seeds, etc., can solve problems such as low safety, affecting the final quality of spinning yarn, and high noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with embodiment the present invention is further described:

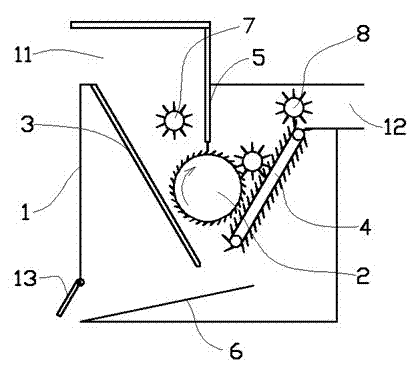

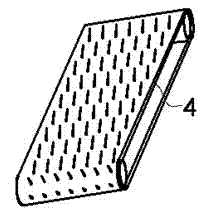

[0014] Such as figure 1 with figure 2 As shown in the embodiment, the V-shaped cotton gin includes a frame 1, an embossed roller 2, a blanking plate 3, and a discharge belt plate 4; 11. The discharge port 12, the blanking plate 3 and the discharge belt plate 4 are placed obliquely. 2 is placed in the middle of the blanking plate 3 and the discharge belt plate 4, and its surface is densely covered with inclined cotton needles. There is a partition 5; the discharge belt plate 4 adopts a belt conveying structure, and the surface of the discharge belt plate 4 is designed with inclined cotton feeding needles.

[0015] The V-gin is used when, as figure 1 As shown, the seed cotton is put into the feed port 11, and the ginning process is completed by the embossing roller 2 inside the frame. Specifically, the partition plate 5 and the embossing roller 2 divide the upper part of the frame 1 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com