Cotton shucking machine

A huller and cotton technology, which is applied in the direction of separating plant fibers from seeds, etc., can solve the problems of cotton fibers peeling in disorder, affecting the quality of cotton, and inability to separate cotton husk residues cleanly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

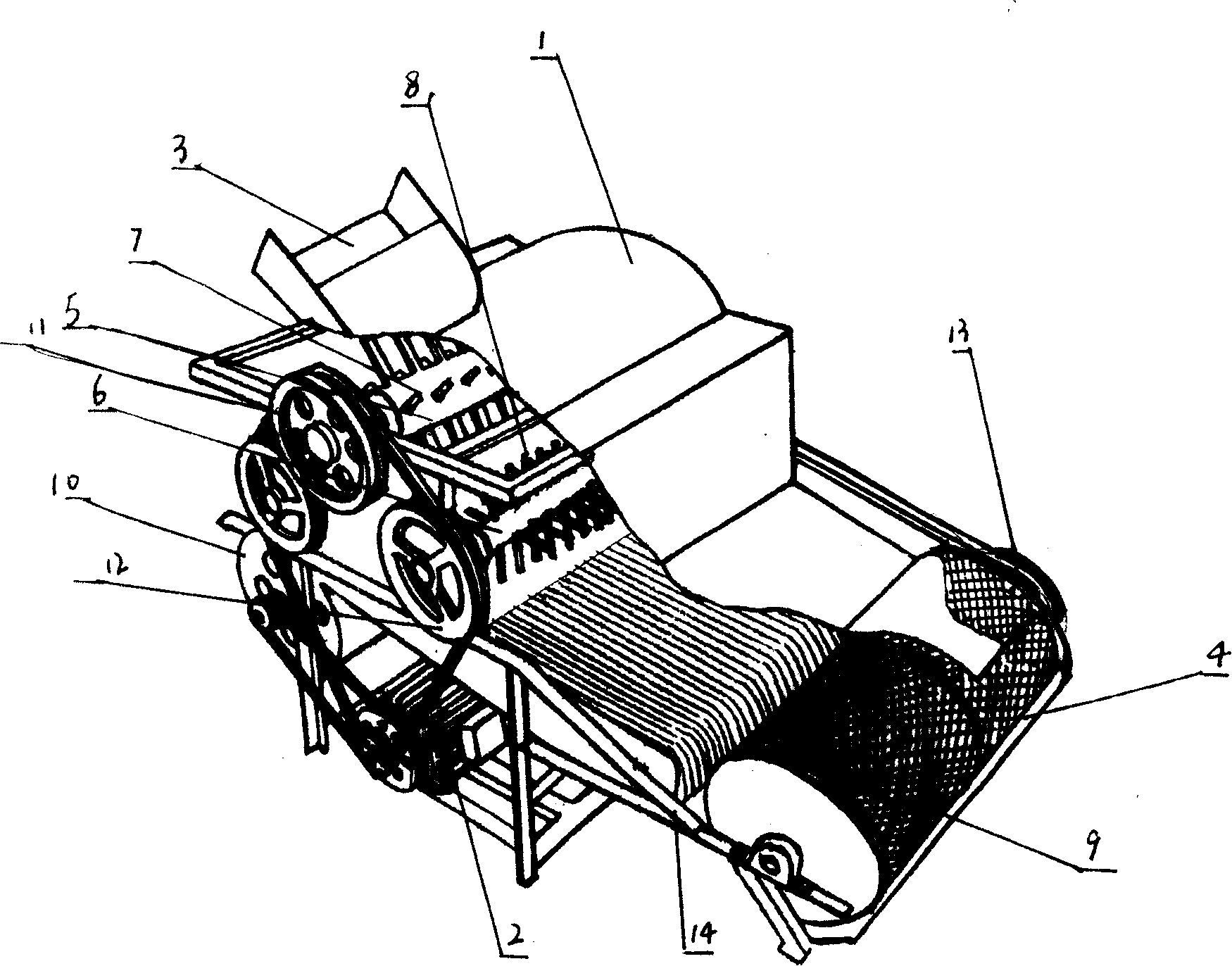

[0010] The following structural drawings further describe the embodiments of the present invention in detail.

[0011] As shown in the figure, the cotton peeling machine is an oblique body with a casing 1 and a motor 2 below the casing 1. The upper end of the inclined body casing 1 has a cotton inlet 3, and the lower end of the casing 1 has a cotton outlet. 4. Install the flower-grabbing main shaft 5 and the flower-grabbing secondary shaft 6 in sequence from the cotton inlet inside the body shell 1. There are several rows of struts on the shaft circumference of the main shaft 5 and the secondary shaft 6, and the struts 7 on the flower-grabbing main shaft 5 The width is greater than the width of the pole 8 on the flower secondary shaft 6. The jacquard cylinder 9 is installed at the 4 cotton outlets. The jacquard cylinder 9 has a cylindrical mesh structure. There is a fan 10 in the body shell 1 below the cotton inlet 3. There is a channel between the secondary axis 6 and the jac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com