Fiber micronaire testing system

A technology of fiber fineness, micronaire, applied in the field of cotton ginning treatment method and device for optimizing cotton quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] DESCRIPTION OF THE PREFERRED EMBODIMENT

[0064] 【Processing Process System】

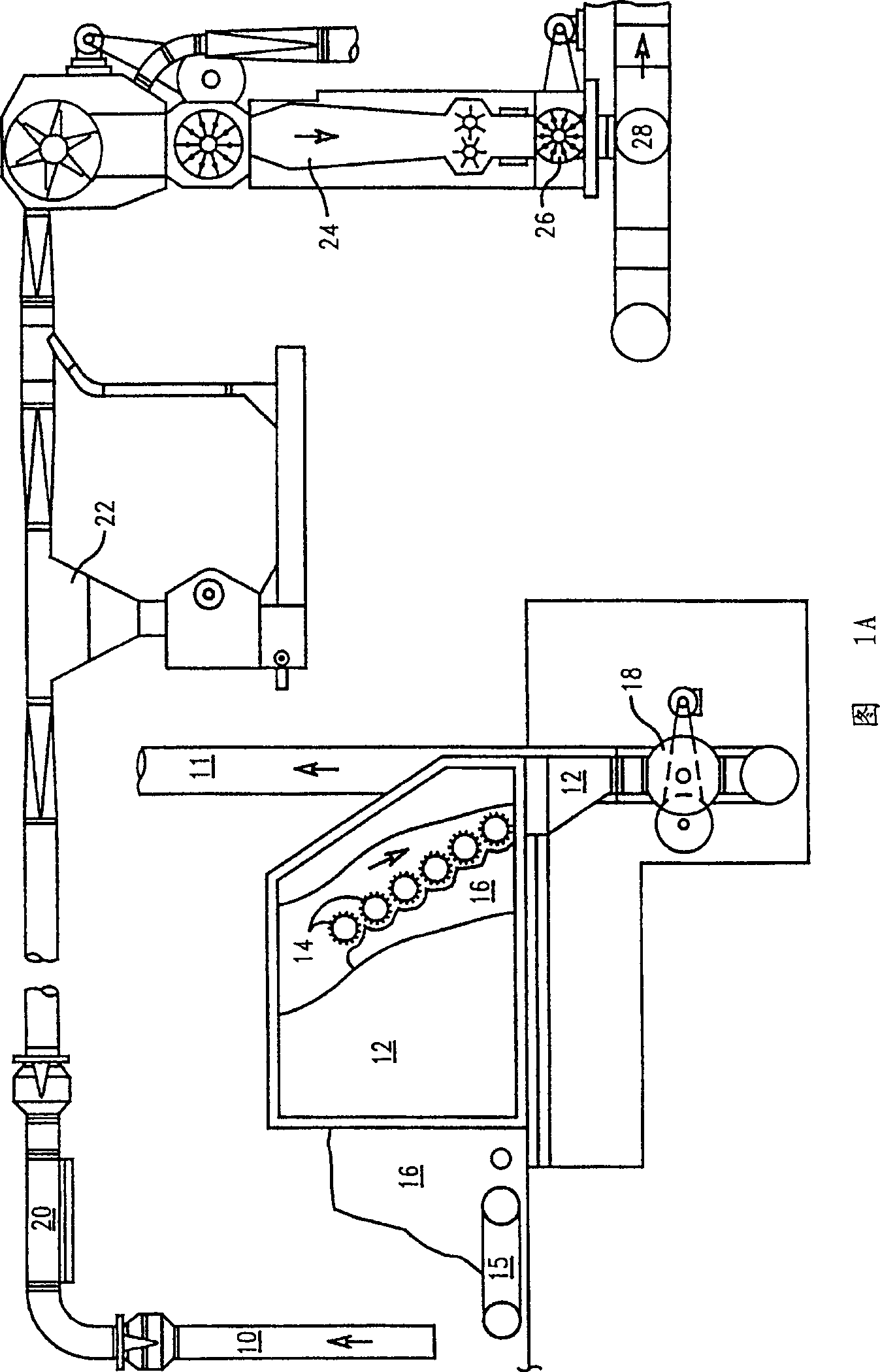

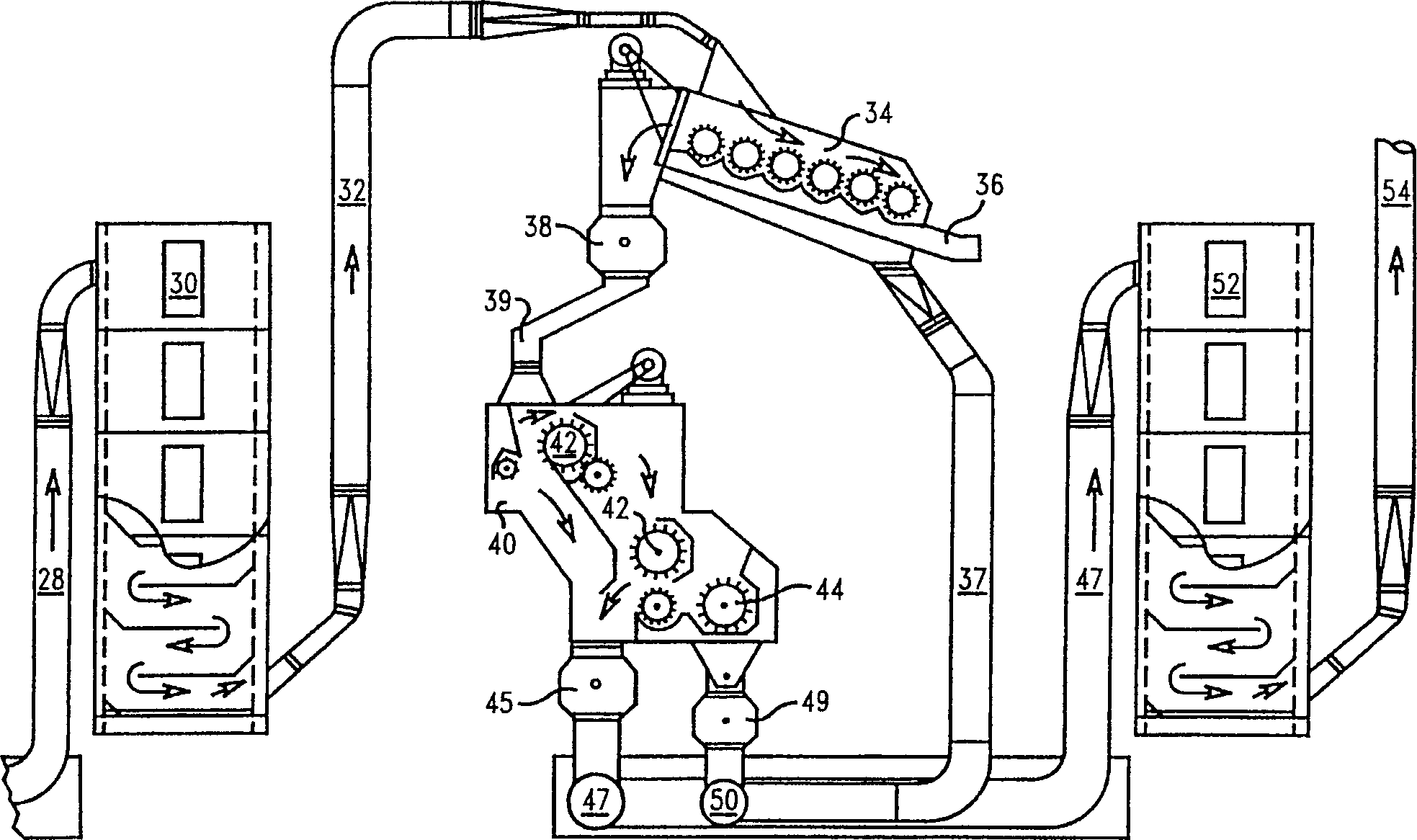

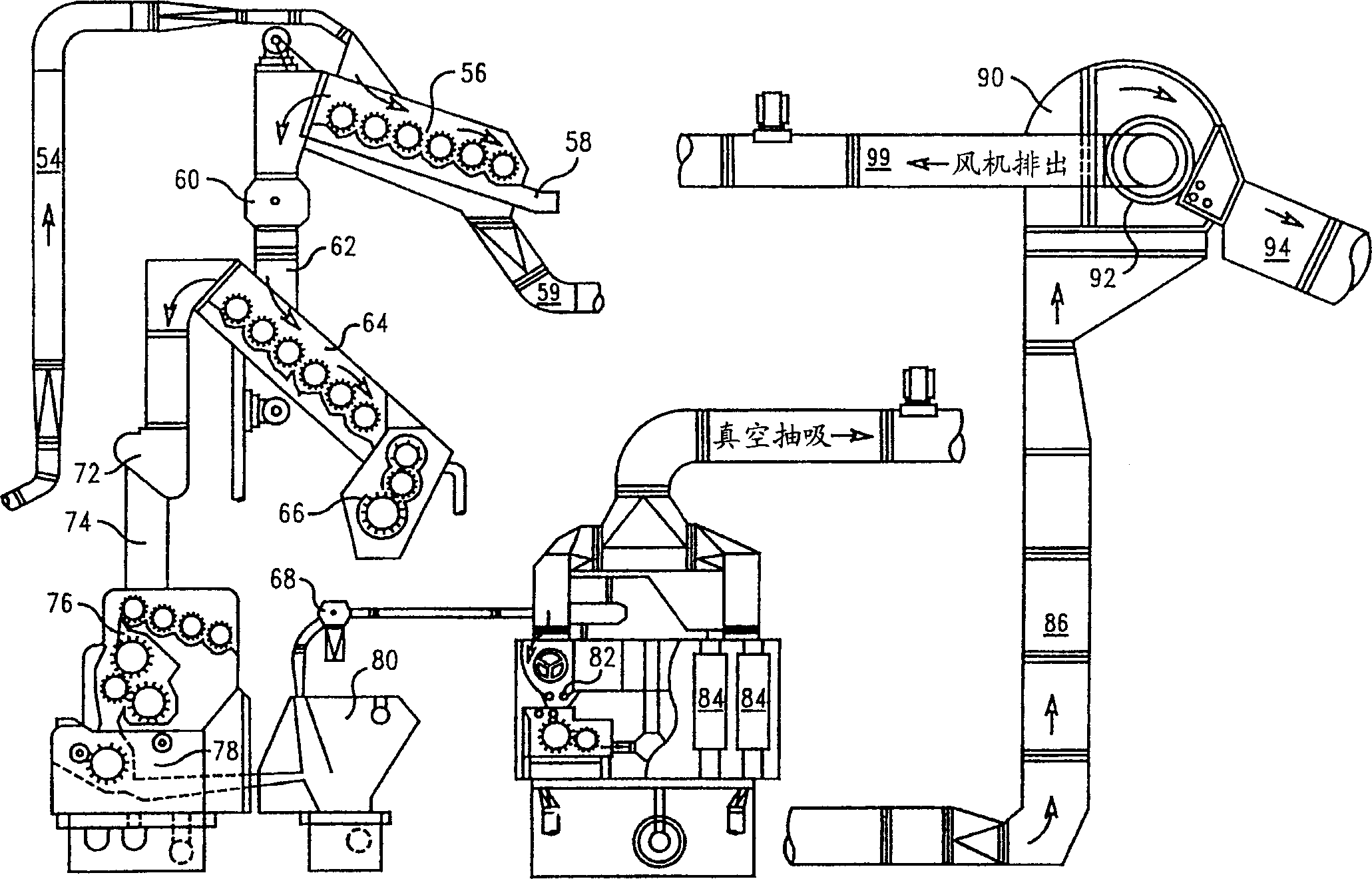

[0065] Figures 1A-1D illustrate a typical cotton ginning system, wherein like reference numerals designate like or similar equipment or components throughout the drawings. Typically, the cotton is conveyed sequentially through and between each treatment station in the airflow enclosed within the air duct. The air flow rate in a telescoping pickup delivery system for seed cotton fluid delivery can be 5500-6000 ft / min (feet per minute). The air flow rate for lint fluid transfer is about 2000-3500 ft / min.

[0066] Cotton can be transported from the growing field in loose chunks or in compacted modules. The conveyance of loose chunks can be sucked into the supply conveying pipe 20 through the telescopic pick-up conveying pipe 10 by means of vacuum suction. Additionally, a railroad car or road caravan sized compaction module 16 is placed on an infeed conveyor 15 for controllably feeding into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com