Method for improving embossing quality of sawteeth

A tooth gin and sawtooth technology, applied in textiles and papermaking, separation of plant fibers from seeds, mechanical treatment, etc., can solve the problems of short length of fiber main body, fiber breakage, fiber quality reduction, etc. The effect of reducing fastness and improving the quality of sawtooth ginning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

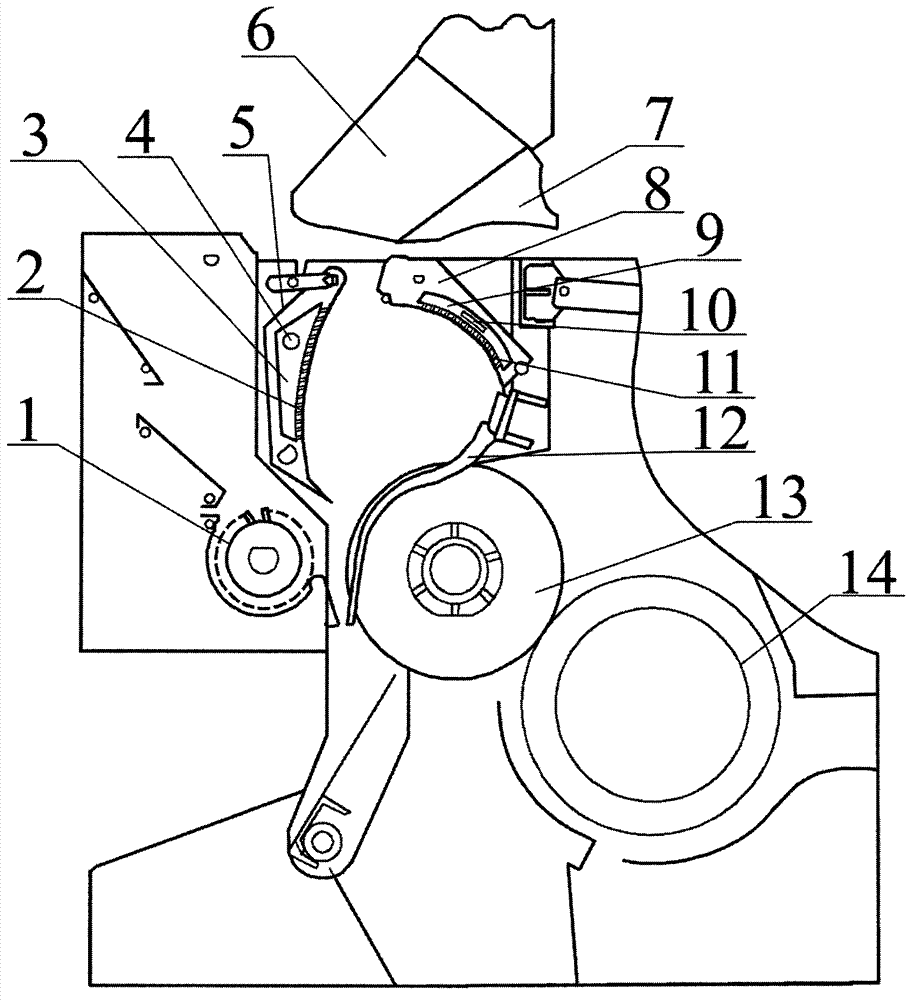

[0008] Combine below figure 1 A method for improving the quality of sawtooth ginning of the present invention is further described in detail.

[0009] See figure 1

[0010] A method for improving the quality of sawtooth ginning, in which evenly distributed air intake micro-holes are arranged on the cotton dripping plate 6 in the feeding area of the sawtooth gin, the cotton dripping plate 6 is connected to a steam channel 7, and the steam channel 7 is externally connected to a steam device, and 100 -200°C high-temperature water vapor or 100-200°C aqueous solution containing 0.1%-6% softener steam is passed into the cotton dripping board 6, and the seed cotton passing through the cotton dripping board is subjected to high temperature heat and humidity treatment, and the cotton fiber on the seed cotton is initially reduced The binding force between cottonseed. After preliminary treatment at high temperature, the seed cotton enters the ginning area composed of the cohesive pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com