Degumming method and device for bast fibers

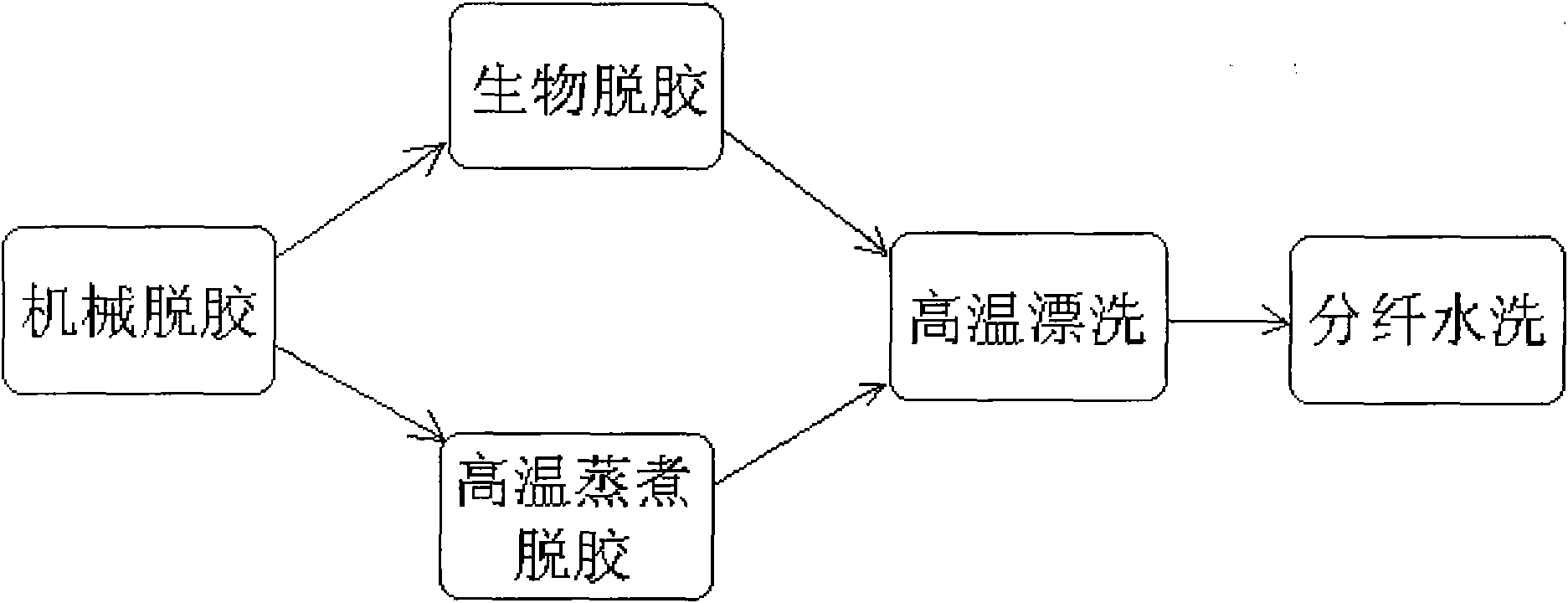

A bast fiber and degumming device technology, which is applied in the directions of separating plant fibers from seeds, fiber processing, and fiber mechanical separation, can solve the problems of unstable bast fiber degumming quality, serious water pollution, and single degumming form. The temperature is stable, the degumming is fully uniform, and the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

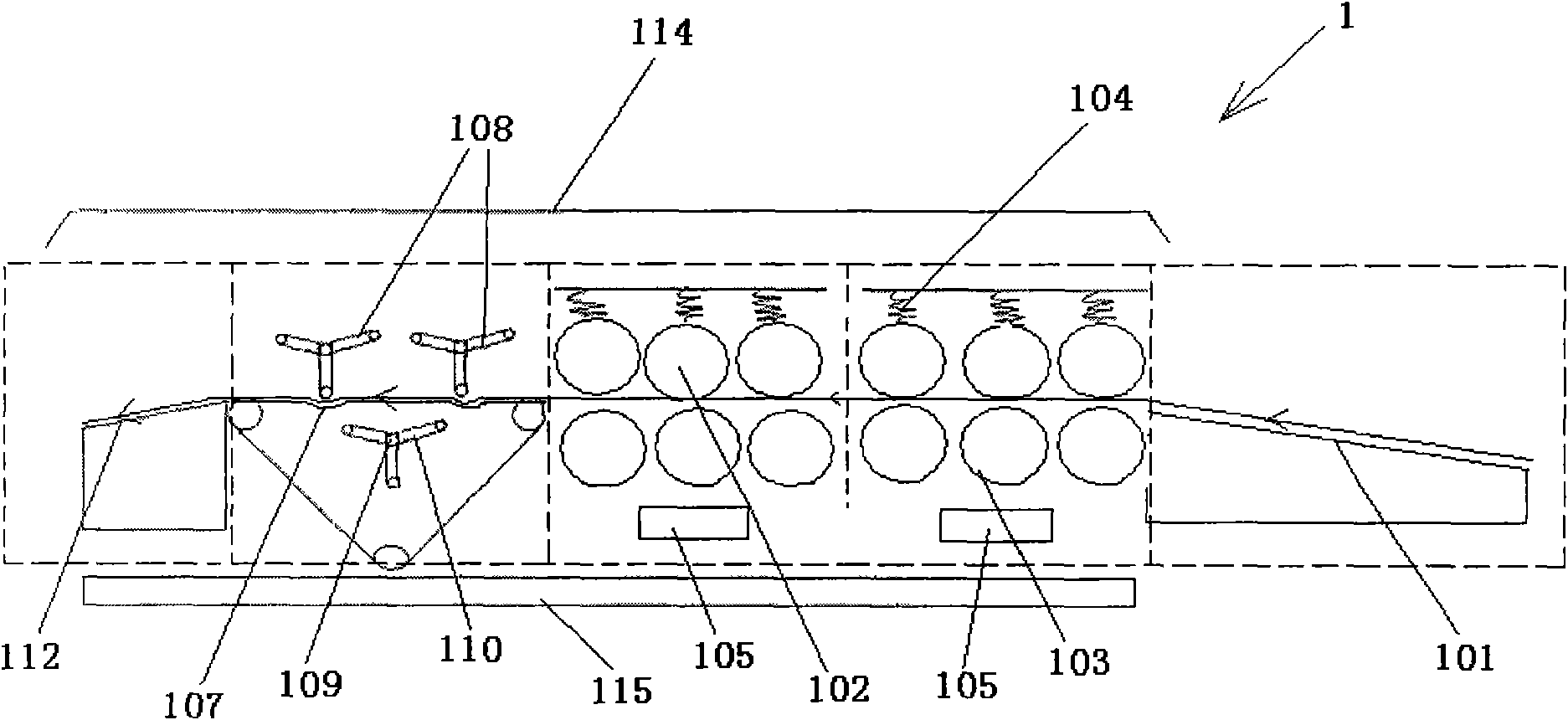

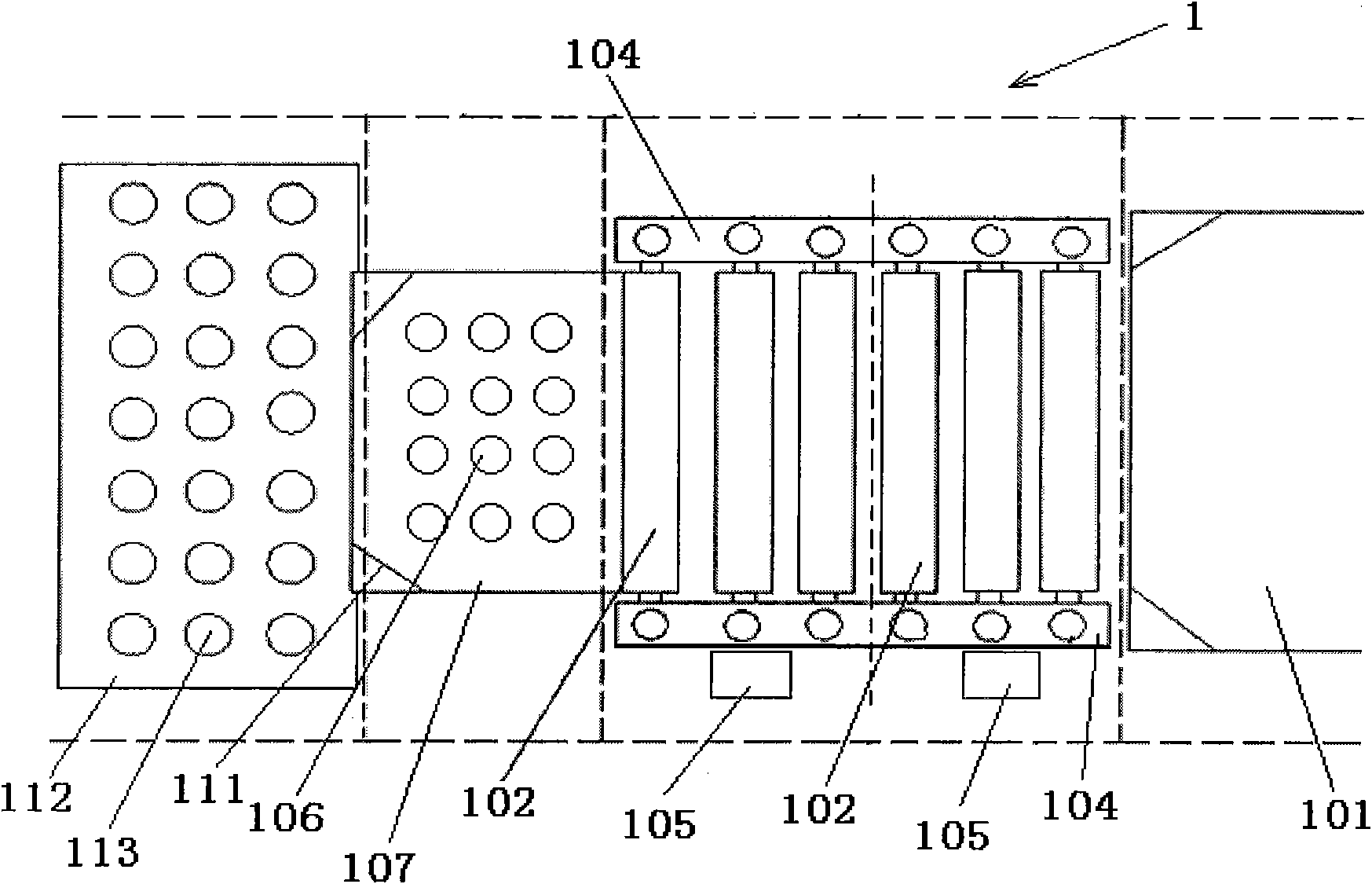

Examples

Embodiment 1

[0094] Embodiment 1, the biological degumming of hemp bast fiber

[0095] Strains: Efficient degumming strain T85-260 (Erwinia sp.): purchased from the Institute of Cannabis, Chinese Academy of Agricultural Sciences, ZL951125648, number CGMCC95 of the National Culture Collection Center.

[0096] Material: hemp hemp skin (hemp raw material hemp skin).

[0097] (1) Seed cultivation

[0098] 1. Primary strain culture

[0099] Medium preparation method: add peptone 0.5%, beef extract 0.1%, yeast powder 0.1%, glucose 0.1%, NaCl 0.1%, KH 2 PO 4 0.01%, adjust the pH value to 7.5, and then sterilize; the sterilization conditions are: 110°C, 5min, to make a culture medium. Pick the strains from the plate, then insert them into the culture medium, and cultivate them. The cultivation process parameters are: 35°C, 3 hours, shaking to make the first-grade strains.

[0100] 2. Secondary strain culture

[0101] Medium preparation method: add peptone 0.5%, beef extract 0.1%, yeast powd...

Embodiment 2

[0123] Embodiment 2, the biological degumming of ramie bast fiber

[0124] Strain: Bacillus alkalophilus strain NTT33-CL301, CCTCC №96009, purchased from China Center for Type Culture Collection (CCTCC).

[0125] Material: ramie hemp skin (ramie raw material hemp skin).

[0126] (1) Seed cultivation

[0127] 1. Primary strain culture

[0128] Medium preparation method: add peptone 3.0%, beef extract 2.0%, yeast powder 2.5%, glucose 3.0%, NaCl 1.5%, (NH 4 ) 2 HPO 4 0.1%, KH 2 PO 4 0.1%, adjust the pH value to 11.0, and then sterilize; the sterilization conditions are: 130°C, 40min, to make a culture medium. Pick the strains from the plate, insert them into the culture medium, and cultivate them. The cultivation process parameters are: 37°C, 12 hours, shaking to make the first-grade strains.

[0129] 2. Secondary strain culture

[0130] Medium preparation method: add peptone 3.0%, beef extract 2.0%, yeast powder 2.5%, glucose 3.0%, NaCl 1.5%, (NH 4 ) 2 HPO 4 0.1%, K...

Embodiment 3

[0152] Embodiment 3, the biological degumming of flax bast fiber

[0153] Strains: strain CXJZ95-198, purchased from the Institute of Hemp, Chinese Academy of Agricultural Sciences.

[0154] Material: flax hemp skin (flax raw material hemp skin).

[0155] (1) Seed cultivation

[0156] 1. Primary strain culture

[0157] Medium preparation method: add peptone 2.0%, beef extract 1.0%, yeast powder 1.5%, glucose 1.5%, NaCl 1%, (NH 4 ) 2 HPO 4 0.01%, KH 2 PO 4 0.05%, adjust the pH value to 6.5, and then sterilize; the sterilization conditions are: 120°C, 20min, to make a culture medium. Pick the strains from the plate, then insert them into the culture medium, and cultivate them. The cultivation process parameters are: 30°C, 8 hours, shaking to make the first-grade strains.

[0158] 2. Secondary strain culture

[0159] Medium preparation method: add peptone 2.0%, beef extract 1.0%, yeast powder 1.5%, glucose 1.5%, NaCl 1%, (NH 4 ) 2 HPO 4 0.01%, KH 2 PO 4 0.05%, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com