Novel automatic cotton suction machine

An automatic and new technology, applied in the field of textile machinery, can solve the problems of damage to the card clothing, winding rollers, and no automatic lifting function of the cotton suction machine, and achieve the effect of ensuring quality and uniform spraying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

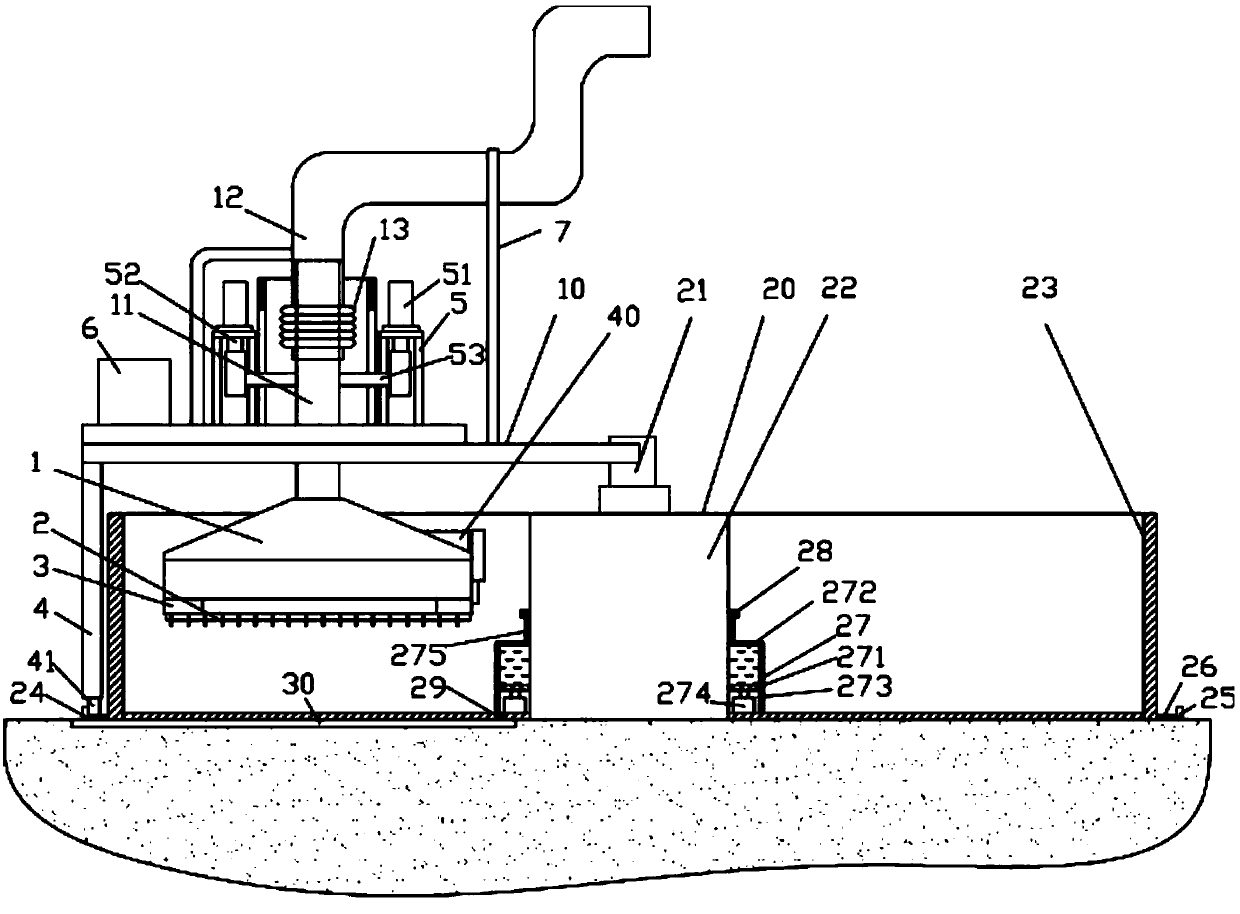

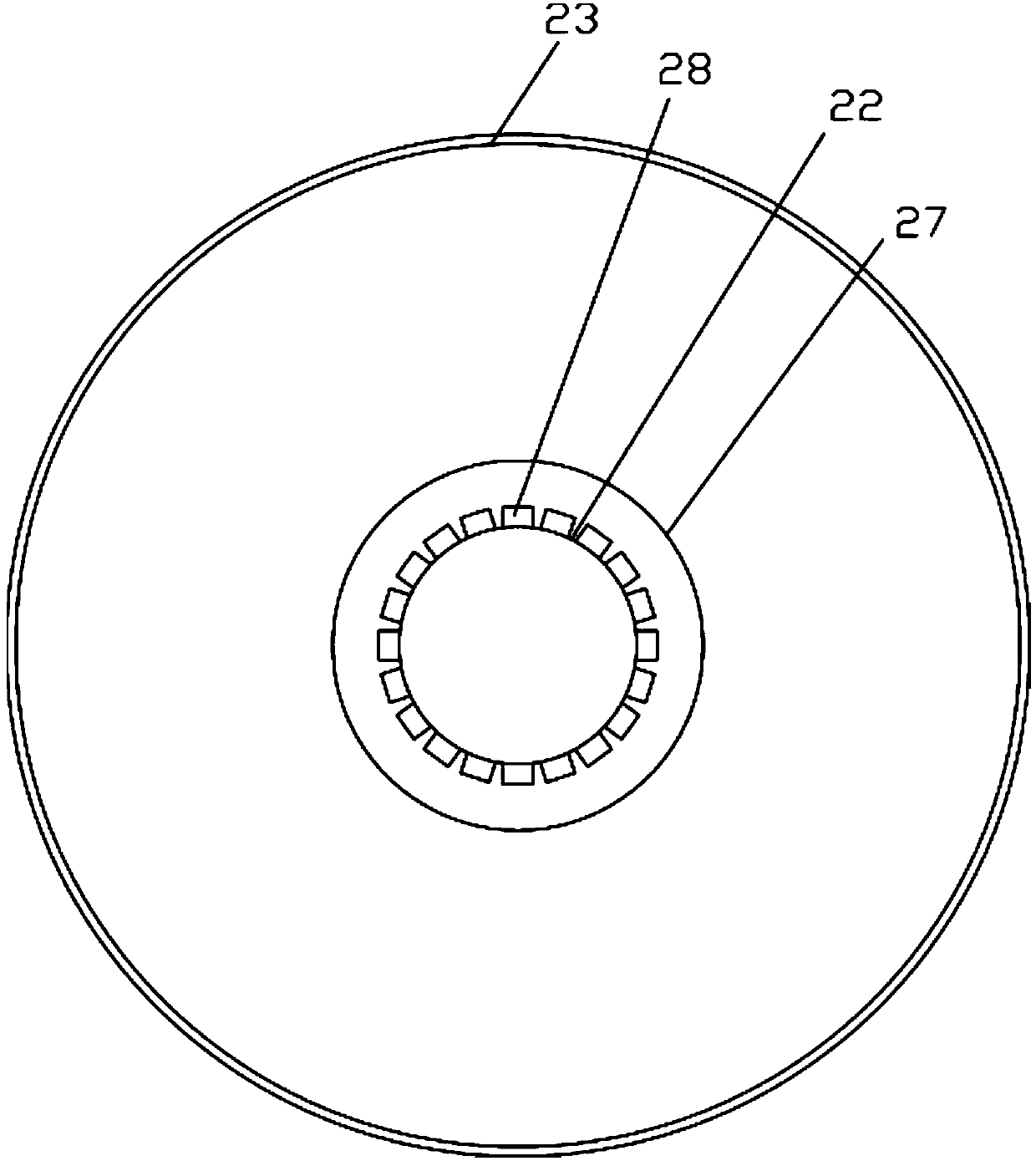

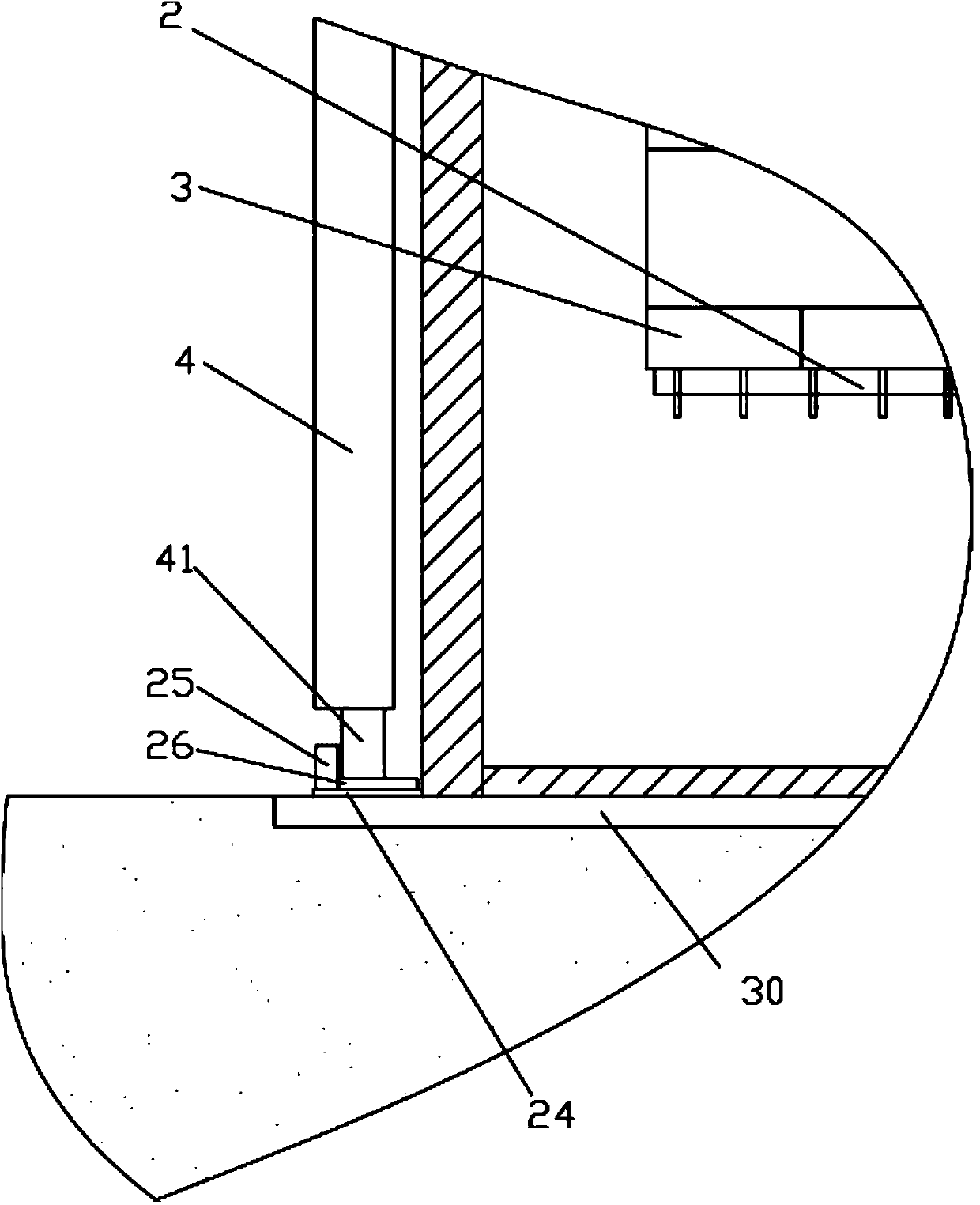

[0020] Examples, see e.g. Figures 1 to 4 As shown, a new type of automatic cotton suction machine includes a cotton picking trolley 10 and an annular silo 20 for placing cotton. The cotton picking trolley 10 includes an inverted funnel-shaped suction cup 1, and a cotton picking trolley is arranged horizontally below the suction cup 1. Beater 2, the both sides of grabbing beater 2 are provided with magnet blocks 3 for removing iron filings, one end of cotton grabbing trolley 10 is fixed on the center shaft 21 of the central shaft mechanism of ring-shaped feed bin 20, the other end of cotton grabbing trolley 10 Support arm 4 bottom ends are fixed with slide block 41, and annular feed bin 20 comprises inner wallboard 22 and outer wallboard 23, and inner wallboard 22 and outer wallboard 23 encircle an annular space that places cotton, and outer wallboard 23 There is an annular guide rail 24 on the outer side, the slider 41 is pressed against the annular guide rail 24, a connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com