Automatic-feeding wool slivering machine complete equipment

A technology of automatic feeding and complete sets of equipment, applied in deburring devices, fiber mixing, textiles and papermaking, etc., can solve the problems of uneven entry of wool into the feeding mechanism, unfavorable continuous production, etc., to ensure continuous production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail below in conjunction with the accompanying drawings and specific embodiments:

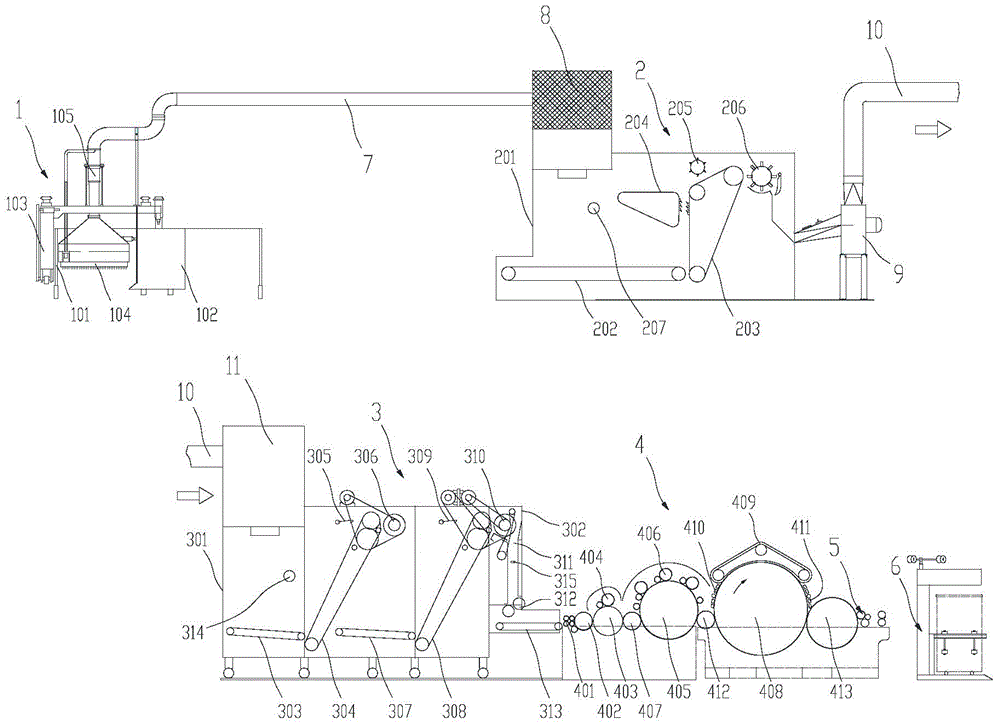

[0026] combine figure 1 As shown, the complete set of wool sliver making equipment for automatic feeding includes a wool grabbing mechanism 1, a wool mixing mechanism 2, a feeding mechanism 3, a carding mechanism 4, a stripping mechanism 5 and a coiling mechanism 6.

[0027] The wool picking mechanism 1 can adopt the existing cotton picking machine in the prior art. Specifically, the hair grasping mechanism 1 includes an outer wall panel 101 , an inner wall panel 102 , a beater frame 103 , a beater 104 and a telescopic tube 105 .

[0028] An annular silo is arranged between the outer wall panel 101 and the inner wall panel 102 . The top of the beater 104 is provided with a bell mouth communicating with the lower end of the telescopic tube 105 , and the upper end of the telescopic tube 105 is connected with the first hair conveying pipe 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com