Disc type bale plucker

A cotton picker and disc type technology, applied in the field of disc type cotton pickers, can solve the problems of labor-intensive, low sensitivity, complicated structure, etc., and achieve the effect of simple structure and reduction of manual or automatic adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

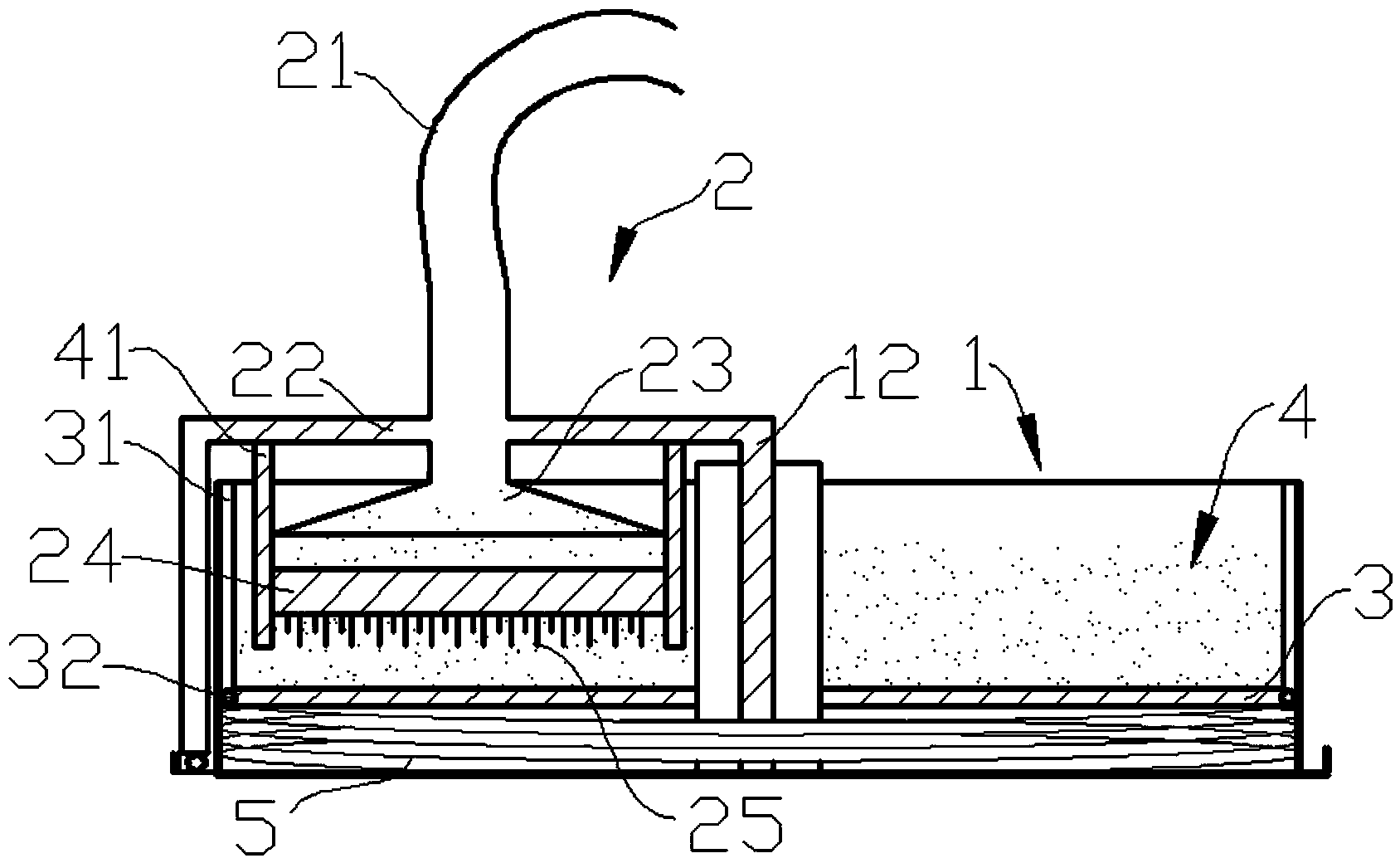

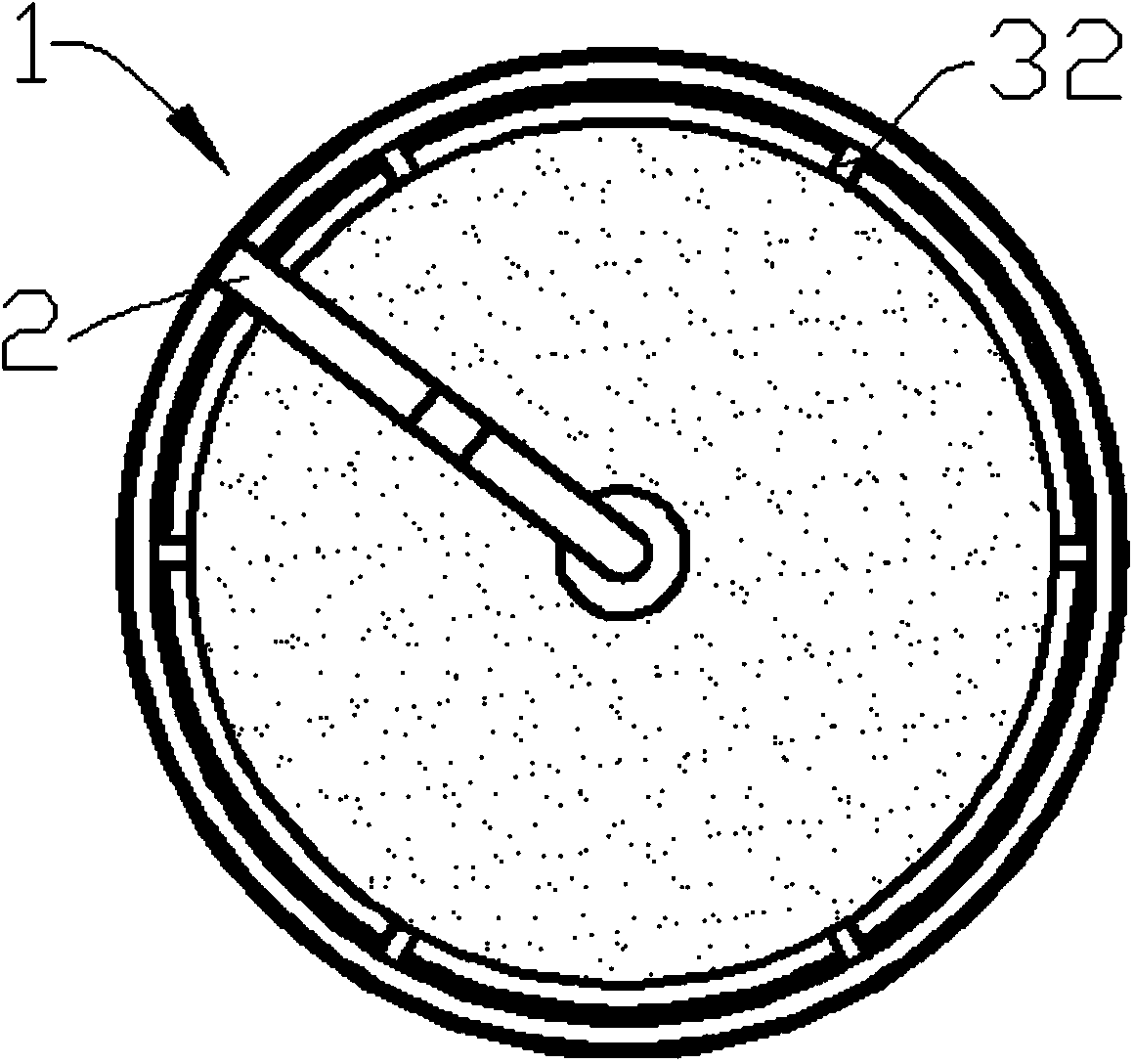

[0011] exist figure 1 In the illustrated embodiment, the disc-type cotton grabbing machine includes a disc base 1 and a cotton picking trolley 2, a rotating shaft 12 is arranged at the axis of the disc base 1, and the cotton picking trolley 2 and the rotating shaft 12 connected, the disc base 1 is divided into upper and lower layers by a baffle plate 3 that can slide in the vertical direction, the upper layer of the disc base 1 places the raw cotton 4 that needs to be taken care of, and the disc base 1 The lower layer is provided with an elastic element 5, which is distributed in a ring shape around the axis of the disc base 1, and the cotton picking trolley 2 includes a cotton feeding tube 21, a cross bar bracket 22, a cotton suction cover 23, and a cotton picking trolley. beaters 24 and ribs 25, the cotton delivery pipe 21 runs through the cross bar bracket 22 and is connected to the cotton suction cover 23, and the cotton grabbing beater 24 is installed on the beater bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com