Reciprocating bale plucker automatic bag detecting and flatting system and control method

A cotton picker and reciprocating technology, which is applied to the automatic bale detection and flat bale system and control field of the reciprocating cotton picker, can solve the problems of inability to evenly grasp, damage, and large amount of cotton, so as to eliminate equipment damage. and safety hazards, avoid visual errors, and improve the quality of sliver

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail below in conjunction with accompanying drawing:

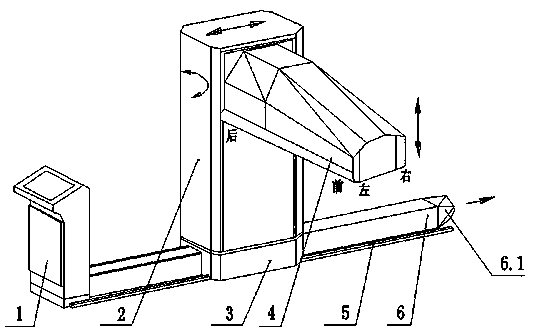

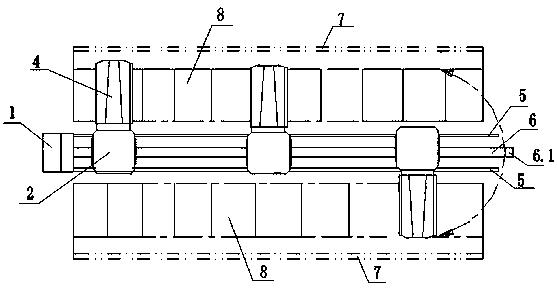

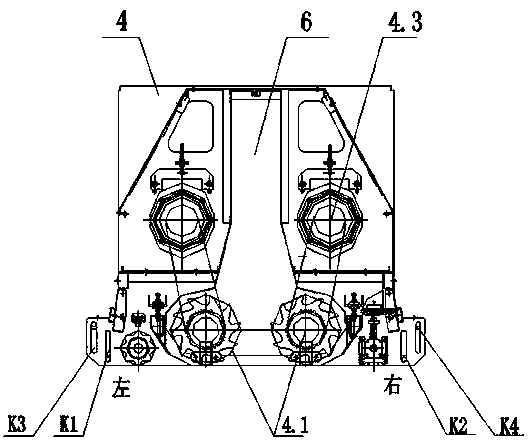

[0026] see Figure 1-Figure 5 , an embodiment of a reciprocating plucking machine automatic bale detection and flat bale system of the present invention, comprising: an electrical console 1, a tower body 2, a tower base 3, a grabbing arm 4, a cotton grabbing roller 4.1 and a cotton grabbing roller blade group 4.2 , track 5, suction tank 6, retaining wall 7. Two pairs of automatic detection photocontrollers are respectively installed on the left and right sides of the grabbing arm 4 along the front and rear length directions of the grabbing arm 4, respectively: lower left photocontroller K1, lower right photocontroller K2, upper left photocontroller K3, and upper right photocontroller. The controller K4, the lower left photocontroller K1 and the lower right photocontroller K2 are installed on the same low plane, the upper left photocontroller K3 and the upper right pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com